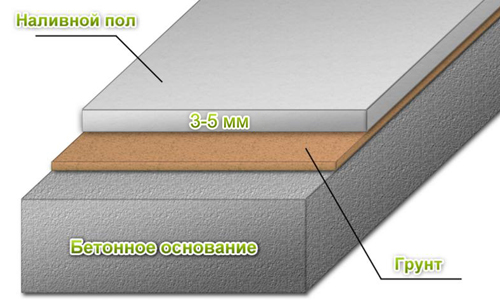

Floor pouring is carried out in both utility and residential areas.premises. In terms of cost, durability and strength, none of the other types of floors used in homes can compare with self-leveling ones. As for the technology of pouring, it is quite simple. Scheme of self-leveling floor.

Scheme of self-leveling floor.

How to fill the floors in the house?

The process of pouring floors can be divided into the following stages:

- the construction of a pillow made of sand and rubble;

- the device of waterproofing;

- laying reinforcing mesh;

- pouring concrete and leveling;

- grouting surface;

- Finishing.

in the house can be done even by a person without experience, but it is advisable to invite an assistant. This will save your own time and energy. Variants of self-leveling floors. Preparatory work is carried out as follows:

Variants of self-leveling floors. Preparatory work is carried out as follows:

The tamping tool can be madehouses. For this, you will need a log 0.5 or 1 m long, which must be nailed to the board. A 10 cm thick layer of sand is poured onto the compacted bottom of the site, watered, and tamped. Next, the same layer of crushed stone with a fraction of 40-50 mm is laid, and tamped again. To level the surface, it is good to pour a little crushed stone chips or sand on top of the crushed stone. Return to the table of contents</a>

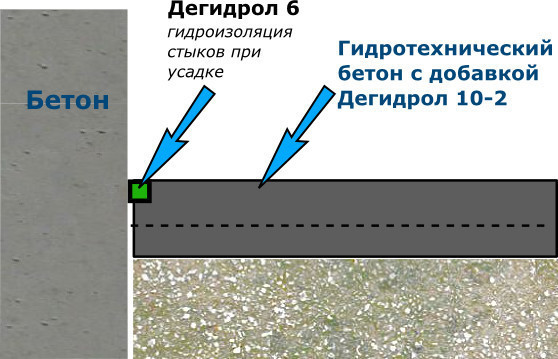

Waterproofing of floors and construction of formwork

To make a waterproofing layerroll materials are used, for example, polyethylene film. To make waterproofing more reliable, it is better to lay polyethylene in several layers. Its sheets should be laid out overlapping, the edges should overlap each other by 15-20 cm. The edges of the film are folded onto the walls to the height at which the pouring is supposed to be done, and fixed there. If the area to be poured is large, the work is carried out using "cards", i.e. rectangular sections of a certain size. The size of such sections is set depending on the productivity of the workers. Formwork is arranged along the perimeter, for which wet, freshly sawn wood or laminated plywood is used. The size of the formwork is calculated depending on how much the workers can pour in one shift. To pour the floor in the house evenly, its thickness should be the same everywhere. Floor waterproofing scheme.To comply with this rule, guides are used, along which the upper boundary of the fill will be set. Rectangular pipes are most often used for this purpose: they can be purchased at construction markets. Edged boards and timber with smooth edges are also suitable. Before pouring the floors, it is better to lubricate the guides with a special agent. Thanks to this treatment, the guides will be easier to separate from the hardened concrete, and the cement milk will be easier to remove. If there is no agent, you can use used machine oil instead. The guides are installed on special pins and brought to a horizontal position, for which a water level, optical level, and building level are used. Return to contents</a>

Floor waterproofing scheme.To comply with this rule, guides are used, along which the upper boundary of the fill will be set. Rectangular pipes are most often used for this purpose: they can be purchased at construction markets. Edged boards and timber with smooth edges are also suitable. Before pouring the floors, it is better to lubricate the guides with a special agent. Thanks to this treatment, the guides will be easier to separate from the hardened concrete, and the cement milk will be easier to remove. If there is no agent, you can use used machine oil instead. The guides are installed on special pins and brought to a horizontal position, for which a water level, optical level, and building level are used. Return to contents</a>

Why reinforce the floor?

To fill the floor correctly, it is necessaryperform reinforcement. This operation helps to make the structure stronger and extends its service life. Fine-mesh mesh is used for reinforcement. Special plastic products can be purchased at building materials markets. It cannot be laid on the ground, since it will have no effect. The mesh must be raised by a third of the screed thickness, this is done using supports. They should be placed on rectangles cut out of asbestos-cement sheets. If the mesh is soft, pins are driven into the ground and the mesh is pulled over them. If it is assumed that the concrete floor will be subject to increased loads, a reinforcement frame is installed. It is made by tying metal rods with a thickness of 8-16 mm. In this case, the concrete mixture will need to be compacted more intensively. Return to contents</a>

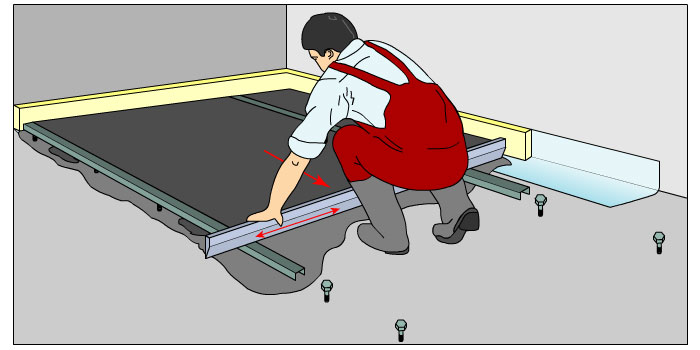

How to fill a concrete floor and level it?

Concrete is poured according to the specifiedbeacons. When pouring the floor, you should try to avoid long breaks in work. When pouring floors for houses, the sites are not very large. If the volumes are large, it is better to rent a concrete mixer than to mix the solution yourself. It should be prepared from cement, crushed stone, sand and water, mixing them in proportions of 1:4:2:0.4. It is better to choose a cement grade of at least M400 or M500. In this case, sand must be taken without any impurities, dirt, clay. To mix the solution, you can use a construction mixer or even a shovel, if the mixing volumes are small. The prepared concrete mixture is dumped into a prepared map, fenced off with formwork, and leveled with a shovel. The movements should be stabbing: this allows you to compact the mass and remove excess air from the concrete mixture. It is more convenient to use a deep vibrator for this. It is lowered into the concrete mixture in a checkerboard pattern. When the cement milk comes to the surface and the crushed stone moves down, the vibration should be transferred to another place. Leveling procedures above the surface should be performed using a rule, resting it on the previously installed guides. Then, using a float, more thorough leveling is carried out. The movements should be semicircular, with a small amplitude. The screed will need to be looked after: its surface should be moistened with water for three days. After that, it is covered with polyethylene film. This will make the concrete dry more uniformly. The screed should be protected from drafts and direct sunlight. Return to contents</a>

Concrete is poured according to the specifiedbeacons. When pouring the floor, you should try to avoid long breaks in work. When pouring floors for houses, the sites are not very large. If the volumes are large, it is better to rent a concrete mixer than to mix the solution yourself. It should be prepared from cement, crushed stone, sand and water, mixing them in proportions of 1:4:2:0.4. It is better to choose a cement grade of at least M400 or M500. In this case, sand must be taken without any impurities, dirt, clay. To mix the solution, you can use a construction mixer or even a shovel, if the mixing volumes are small. The prepared concrete mixture is dumped into a prepared map, fenced off with formwork, and leveled with a shovel. The movements should be stabbing: this allows you to compact the mass and remove excess air from the concrete mixture. It is more convenient to use a deep vibrator for this. It is lowered into the concrete mixture in a checkerboard pattern. When the cement milk comes to the surface and the crushed stone moves down, the vibration should be transferred to another place. Leveling procedures above the surface should be performed using a rule, resting it on the previously installed guides. Then, using a float, more thorough leveling is carried out. The movements should be semicircular, with a small amplitude. The screed will need to be looked after: its surface should be moistened with water for three days. After that, it is covered with polyethylene film. This will make the concrete dry more uniformly. The screed should be protected from drafts and direct sunlight. Return to contents</a>

Surface grinding

During the process of concrete hardening on the surfaceCement milk is released and hardens in the form of a smooth film. In the future, this may create problems with the adhesion of the finishing coat and the concrete floor, which will be fragile. Therefore, some time after pouring (from several hours to a day), it is necessary to grind the surface. This will help get rid of the film. This operation is easier to perform using special grinding devices, but you can also do it with a hand grinder, for which you should purchase corundum meshes. The resulting surface must be regularly moistened for about a week so that the concrete does not dry out and crack. The floor reaches maximum strength in 4-5 weeks. If the surface is not very smooth when pouring the concrete mixture, you will need to apply a screed. For this, it is better to choose a self-leveling compound, which is poured onto the base and leveled using a special brush. After this, the mixture is rolled with a needle roller to remove air bubbles. Such a screed will dry for 7-14 days. After this, you can proceed to the execution of the finishing coat.