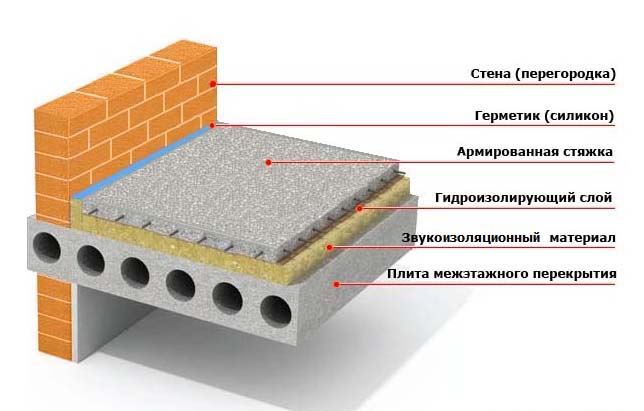

The most common method of alignmentfloors today is the installation of screeds. This is due to the fact that the vast majority of finishing coatings, including, for example, parquet, laminate or tiles, require a flat and durable base. Scheme of reinforced floor screed.The decision to install a screed is made in one of several cases, such as: the need to obtain a monolithic surface, the use of soil as a base for the screed, the requirement to bring the floor to the desired level or the need to arrange a certain slope. In addition, a concrete screed allows you to save money, since such a technology is the most budget option among others. You can fill the screed using expanded clay concrete, as well as foam concrete or perlite concrete, mixtures with such compositions allow you to reduce the weight of the floor and make it thermally insulating.

Scheme of reinforced floor screed.The decision to install a screed is made in one of several cases, such as: the need to obtain a monolithic surface, the use of soil as a base for the screed, the requirement to bring the floor to the desired level or the need to arrange a certain slope. In addition, a concrete screed allows you to save money, since such a technology is the most budget option among others. You can fill the screed using expanded clay concrete, as well as foam concrete or perlite concrete, mixtures with such compositions allow you to reduce the weight of the floor and make it thermally insulating.

Tools and materials

Tools for floor screed: beacons, basin, spatula, level, tape measure, roller, cutter.

Tools for floor screed: beacons, basin, spatula, level, tape measure, roller, cutter.

- Master OK;

- profiles;

- armature;

- Scotch;

- cement;

- sand;

- concrete mixer;

- capacity;

- level;

- rule;

- putty knife;

- roulette;

- Master OK;

- the trowel;

- rope;

- pliers;

- wire;

- self-tapping screws;

- metal grid;

- film;

- profiles.

Return to Contents</a>

Preparation of a mixture for pouring screed

The ratio between the components of the concrete mixture for floor screeds. In order to prepare a mixture for pouring the floor, it is necessary to use materials in the following proportions:

The ratio between the components of the concrete mixture for floor screeds. In order to prepare a mixture for pouring the floor, it is necessary to use materials in the following proportions:

- 3 parts of sand;

- 1 part of cement;

- 1/10 pieces of calcareous dough.

As an alternative, the following material proportions can be used:

- 2 parts of sand;

- 1 part of cement;

- 3 pieces of rubble, replace the last one with gravel.

To prepare a light mixture you shoulduse M-400 cement and expanded clay. The mixture should be homogeneous and have a thick consistency for any recipe. It is not recommended to add excess water to the composition, as this will reduce the strength of the screed. The solution must be used within 2 hours after preparation. Return to contents</a>

The preparatory work process

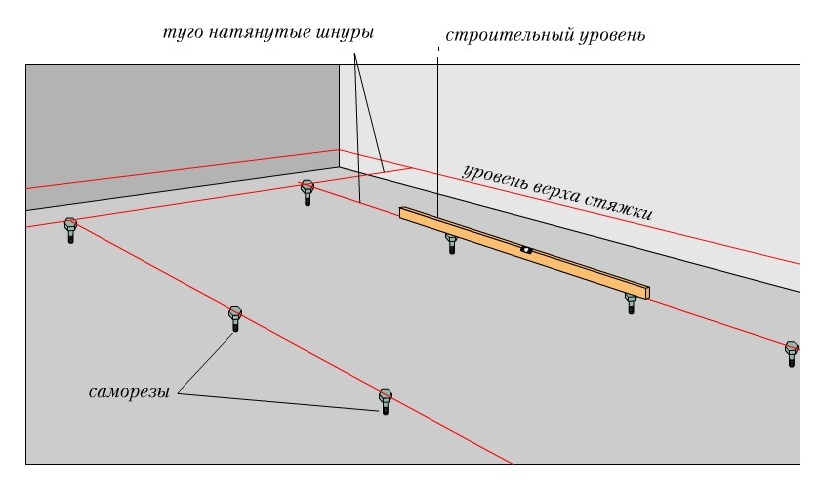

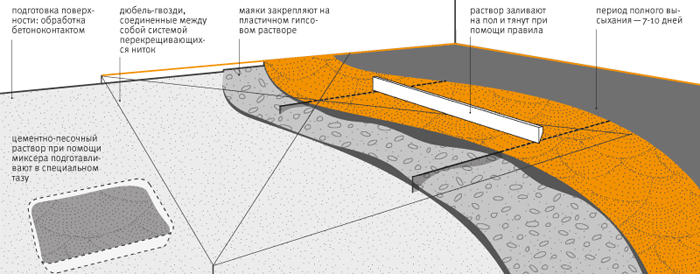

Before starting work, you should decide whichthe floor screed will have a thickness. If there are differences in height on the base that exceed 5 cm, then first you should level it using a concrete base made of M-150 concrete, which can be replaced with M-200 concrete. If the concrete is supposed to be poured onto compacted soil, it will be necessary to arrange a floor screed with a thickness of 150 mm. If the work is carried out on an existing concrete base, about 80 mm of screed thickness will be required. Scheme of beacon installation.In order to get a level concrete floor, it is necessary to put marks in the corners and on the walls of the room in advance using a level. The smaller the step with which these marks are put, the more convenient it will be to mark the level of the screed. After placing the marks, it is necessary to connect them along the perimeter of the room. Self-tapping screws will simplify the process; they need to be screwed into the walls and a cord pulled between them. This will allow you to mark the zero level. The surface of the floors, before pouring the screed, should be waterproofed to prevent the floor slabs from getting wet and water from leaking from the concrete composition downwards. Polyethylene can act as a waterproofing agent, its thickness can vary from 100 to 300 microns, roofing felt, as well as bitumen paper, polymer membranes will also do. The material should be laid with an overlap, connecting the joints with tape. The film should be laid so that its edges extend above the zero level. You can waterproof floors with hydrostekloizol. It must be applied in 2 layers, and the total thickness of the waterproofing agent in this case should be 5 mm. This will also insulate the floor. The strength characteristics of the floors can be increased by laying reinforcement. This can be either a mesh or a volumetric frame. It is also permissible to use steel fiber, but it should be added to the mixture during the mixing of concrete. The best option is to use combined reinforcement.

Scheme of beacon installation.In order to get a level concrete floor, it is necessary to put marks in the corners and on the walls of the room in advance using a level. The smaller the step with which these marks are put, the more convenient it will be to mark the level of the screed. After placing the marks, it is necessary to connect them along the perimeter of the room. Self-tapping screws will simplify the process; they need to be screwed into the walls and a cord pulled between them. This will allow you to mark the zero level. The surface of the floors, before pouring the screed, should be waterproofed to prevent the floor slabs from getting wet and water from leaking from the concrete composition downwards. Polyethylene can act as a waterproofing agent, its thickness can vary from 100 to 300 microns, roofing felt, as well as bitumen paper, polymer membranes will also do. The material should be laid with an overlap, connecting the joints with tape. The film should be laid so that its edges extend above the zero level. You can waterproof floors with hydrostekloizol. It must be applied in 2 layers, and the total thickness of the waterproofing agent in this case should be 5 mm. This will also insulate the floor. The strength characteristics of the floors can be increased by laying reinforcement. This can be either a mesh or a volumetric frame. It is also permissible to use steel fiber, but it should be added to the mixture during the mixing of concrete. The best option is to use combined reinforcement. Screed filling diagram.The reinforcing mesh should be laid with an overlap and then tied with wire. For this, you can use a welded steel mesh with a cell size of 100x100 or 150x150 mm. If you plan to arrange a thin layer of screed, the mesh should be laid on mounting stands. If you mount it directly on the surface of the subfloor, this can lead to cracking of the concrete. Next, you can install beacons that will allow you to level the poured concrete. To do this, you should use profiles that should be set at zero level. This stage involves the initial arrangement of the bases-supports on which the profiles will be mounted. For a strong fastening of the profiles, you can use gypsum. These works must be carried out a day before you plan to carry out the screed of the floors. You can also use another option for fastening the guides, which involves the use of self-tapping screws. Correcting their position will allow you to adjust the height of the beacons. The step between the beacons will be determined by the length of the rule. Return to Contents</a>

Screed filling diagram.The reinforcing mesh should be laid with an overlap and then tied with wire. For this, you can use a welded steel mesh with a cell size of 100x100 or 150x150 mm. If you plan to arrange a thin layer of screed, the mesh should be laid on mounting stands. If you mount it directly on the surface of the subfloor, this can lead to cracking of the concrete. Next, you can install beacons that will allow you to level the poured concrete. To do this, you should use profiles that should be set at zero level. This stage involves the initial arrangement of the bases-supports on which the profiles will be mounted. For a strong fastening of the profiles, you can use gypsum. These works must be carried out a day before you plan to carry out the screed of the floors. You can also use another option for fastening the guides, which involves the use of self-tapping screws. Correcting their position will allow you to adjust the height of the beacons. The step between the beacons will be determined by the length of the rule. Return to Contents</a>

Pour concrete tie

Concrete should be laid on the floor with a shovel, afterwhich you can start leveling it with a rule. Then the base can be leveled with a trowel and get rid of the beacons. The scheme for laying the screed may involve following different technologies. One of them involves starting work from the far corner of the room, the resulting strips will need to be connected to each other, and then filling the spaces left by the beacons with mortar. It is permissible to lay several strips at a distance from each other, after which the distance between them will also need to be filled with the mixture. The screed will harden within half a day, after which its surface will need to be sprayed with water for several days. This is necessary for a slower drying process of the solution, which will allow you to get a greater strength of the base. If you are wondering how to properly pour the screed, then you should also know that the technology involves the need for final leveling of the floor, which has already hardened. This stage is called grinding, and it is carried out using a grinding machine. During the process of hardening of the screed, it can acquire cracks. Even during operation, the floor can crack, which can lead to deformation of the house. This can be avoided by eliminating the rigid adhesion of the floor and walls. Therefore, it will be necessary to make seams, which will be located along the perimeter of the room and around the columns. The seams can be cut using a seam-forming strip, which must be used in a non-hardened base, cutting can also be done after the concrete has hardened. This should be done 12 hours after grouting the surface. The seams should be straight, their width should be 1.3 cm, and the depth - 1/3 of the thickness of the concrete. In the arranged seams, it is necessary to lay cords like Viloterm, and then fill them with polyurethane sealant. The screed will harden within 25 days, this process can be extended using polyethylene film. If you follow all the above rules for installing a concrete floor screed, you can get a fairly strong surface that will act as a reliable base for any finishing coating offered by the market. It should be remembered that the quality of the work and the durability of the final floor finish will depend on how well the concrete screed is installed, as well as whether it retains its quality and strength characteristics.