How to make a floor screed correctly? This question worries not only numerous new residents, but also people who have decided to make a major renovation. Installation of floor screed.It is undeniable that only professional craftsmen can make a perfect screed. However, their work costs money, and it is not a fact that the hired team will consist of high-class professionals. Therefore, some people decide to do the screed themselves. There is nothing particularly difficult in this work. It is enough to follow the instructions to arrange a correct, durable and reliable base for laying the floor.

Installation of floor screed.It is undeniable that only professional craftsmen can make a perfect screed. However, their work costs money, and it is not a fact that the hired team will consist of high-class professionals. Therefore, some people decide to do the screed themselves. There is nothing particularly difficult in this work. It is enough to follow the instructions to arrange a correct, durable and reliable base for laying the floor.

What does the properly made screed mean?

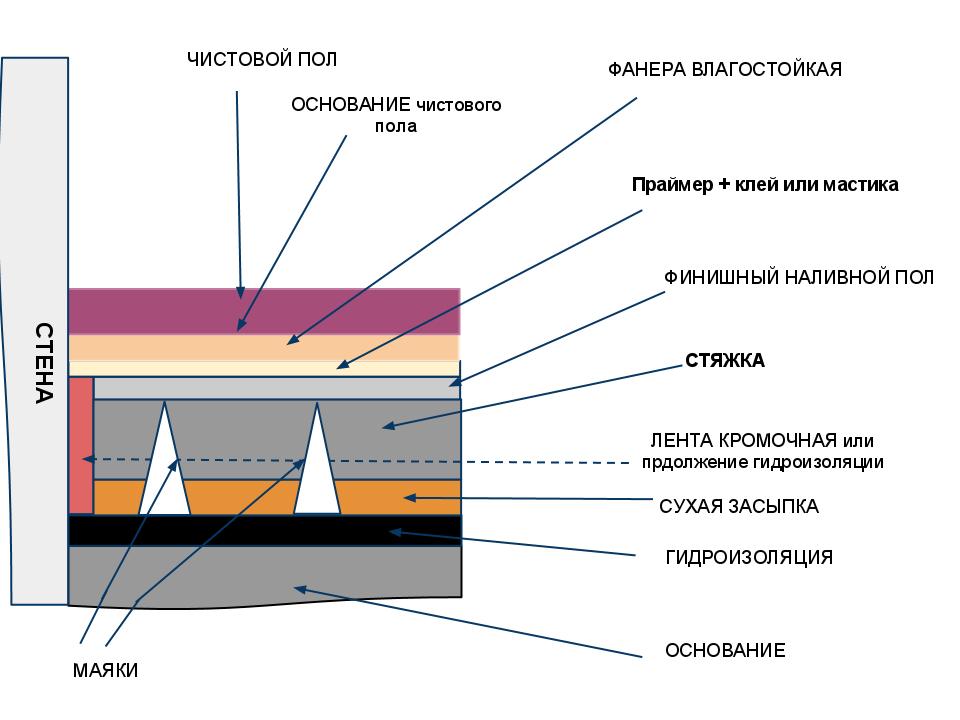

Dry floor screed installation diagram. This means:

Dry floor screed installation diagram. This means:

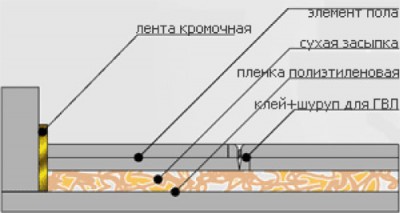

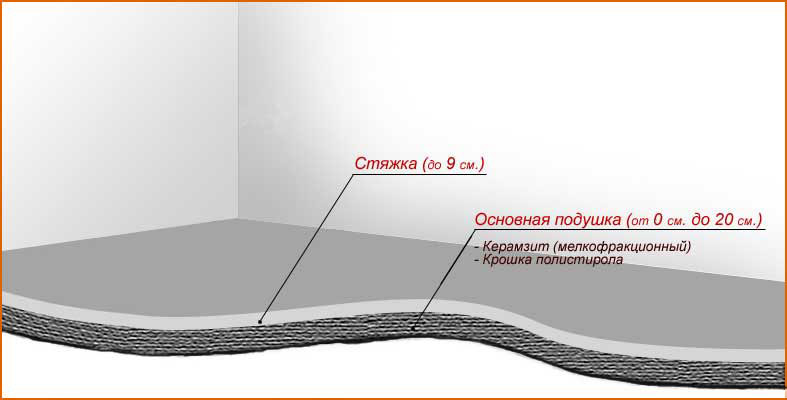

When laying a floor screed, you need to start by assessing the conditionold floor. First, remove the old floor covering, if there is one. It doesn't matter what it is: modern laminate, old parquet or regular floorboards. All of this needs to be removed. Scheme of laying materials for dry floor screed.Now it is necessary to inspect the old screed. If only small chips or depressions are visible on it, then it can be left, and a new one can be made on top of the old one. If the concrete base is crumbling, swells or has large "holes", then the most reliable solution will be complete removal of the old screed, down to the concrete slab. The exposed concrete slab also requires close attention. When inspecting it, you need to do the following:

Scheme of laying materials for dry floor screed.Now it is necessary to inspect the old screed. If only small chips or depressions are visible on it, then it can be left, and a new one can be made on top of the old one. If the concrete base is crumbling, swells or has large "holes", then the most reliable solution will be complete removal of the old screed, down to the concrete slab. The exposed concrete slab also requires close attention. When inspecting it, you need to do the following:

The preliminary work is finished, we can move on to the main work: constructing a new screed. Return to the table of contents</a>

How to properly make a floor screed in a "grandfather's way"?

Floor scheme with cement-sand screed. "The old-fashioned way" is to use a regular concrete-cement mixture to level the floor. The work is divided into 3 stages:

Floor scheme with cement-sand screed. "The old-fashioned way" is to use a regular concrete-cement mixture to level the floor. The work is divided into 3 stages:

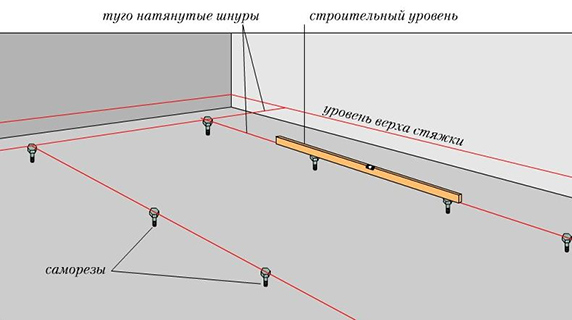

Why is it important to follow this particular order?Why can't you first prepare the mixture, then install the beacons, or do without them altogether and just pour the screed right away? The fact is that the concrete mixture dries relatively quickly. And in order to install the beacons necessary for leveling, a certain skill is needed. Therefore, experienced craftsmen recommend this particular work algorithm. To place the beacons, you need to follow several simple rules:

Scheme of installation of beacons.When all the marks are in place, the floor is lightly moistened. You can use a roller or a sprayer: whichever is more convenient. Experience shows that the best composition of a traditional concrete mix consists of one part cement and three parts sand. Attention! The sand must be well sifted and cleaned of impurities. For this, use a construction sieve or pieces of fine mesh. It is impossible to make a screed using unprepared sand: the heterogeneity of the fractions will prevent the formation of a smooth surface. Preparing a solution for a floor screed is similar to kneading dough. The more thoroughly the solution is mixed, the stronger the result will be. The process should go according to the following scheme:

Scheme of installation of beacons.When all the marks are in place, the floor is lightly moistened. You can use a roller or a sprayer: whichever is more convenient. Experience shows that the best composition of a traditional concrete mix consists of one part cement and three parts sand. Attention! The sand must be well sifted and cleaned of impurities. For this, use a construction sieve or pieces of fine mesh. It is impossible to make a screed using unprepared sand: the heterogeneity of the fractions will prevent the formation of a smooth surface. Preparing a solution for a floor screed is similar to kneading dough. The more thoroughly the solution is mixed, the stronger the result will be. The process should go according to the following scheme:

Return to Contents</a>

Why is it better to do a floor screed together?

Scheme of cement-sand screed on wooden joists. It is better if at least two people participate in the construction of the screed. This is explained by several reasons:

Scheme of cement-sand screed on wooden joists. It is better if at least two people participate in the construction of the screed. This is explained by several reasons:

Now the mixture is spread out in small portionsconcrete base and level it first with a trowel, then with a rule, using the beacons as a guide. It is better to start work from the far corner, gradually moving towards the exit. It is important to remember:

If the solution is prepared correctly, the work algorithm is followed precisely, then after 20-35 days:

Return to Contents</a>

The cost of a self-leveling compound

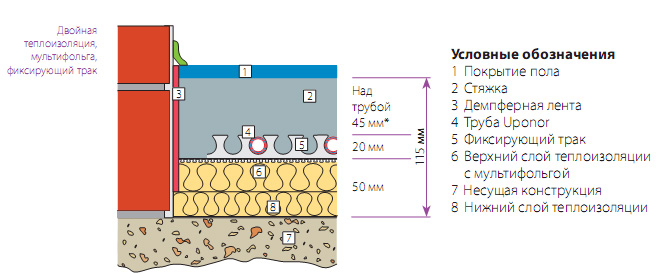

Scheme of floor screed with expanded clay.How to make a screed using a self-leveling mixture? The first stages of work, up to the placement of beacons, are no different from pouring ordinary cement. As soon as the base is prepared, it is best to make an estimate. A self-leveling mixture is much more expensive than a regular one, for the following reasons:

Scheme of floor screed with expanded clay.How to make a screed using a self-leveling mixture? The first stages of work, up to the placement of beacons, are no different from pouring ordinary cement. As soon as the base is prepared, it is best to make an estimate. A self-leveling mixture is much more expensive than a regular one, for the following reasons:

There are very few people whoarrange a full-fledged thick screed from a self-leveling mixture. Usually they use a trick: pour the "fast" mixture onto a regular screed. Its consumption will decrease several times, and the effect will be very good: the screed will be even, smooth, durable. If it is decided to use a self-leveling mixture, then the slab should be covered with two layers of primer. Usually the packaging indicates which primer is preferable. Naturally, the second layer is applied after the first one has completely dried, and the solution is poured no earlier than a day after the primer has dried. While the primer is drying, you should carefully study the instructions for using the mixture. It will indicate:

It is good if this data is studied before purchase, and just refreshed in memory before pouring. The technology of laying self-leveling mixture is quite simple:

The floors are left for 6-8 hours. After this time, you can walk on the screed. Return to the table of contents</a>

Self-leveling mixture: bad or good?

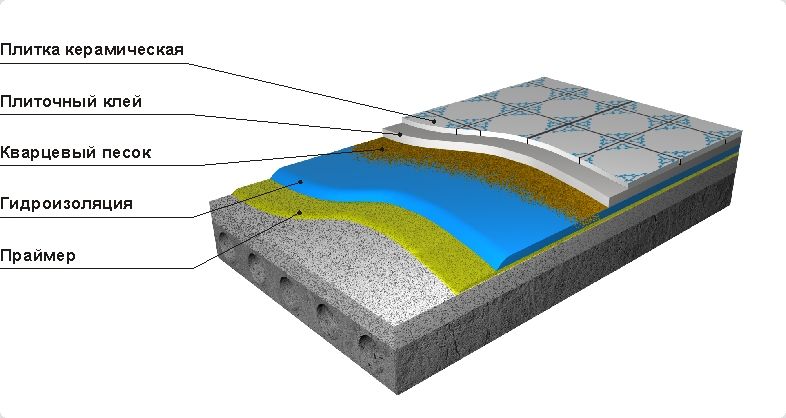

Floor screed scheme for floor tiles. Like any material, this composition has its "pros" and "cons". Pros:

Floor screed scheme for floor tiles. Like any material, this composition has its "pros" and "cons". Pros:

Cons:

Now you know how to properly construct a floor screed from different materials. All you have to do is stock up on them and get to work.