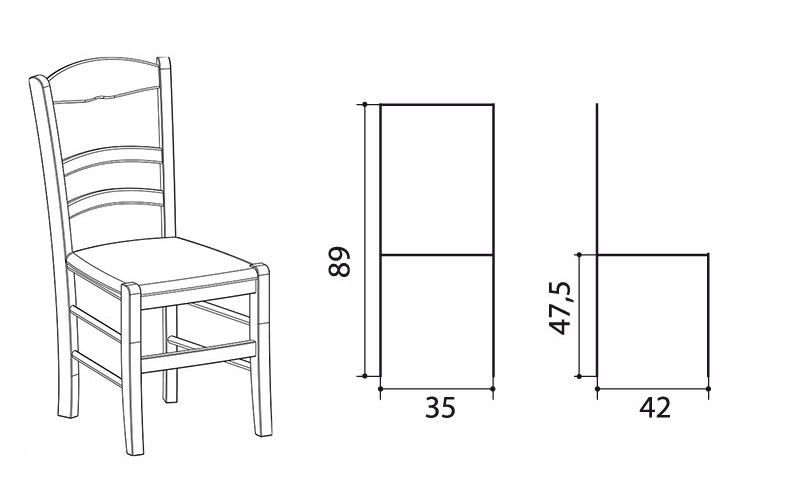

Chairs can be found in modern furniture storesin a large assortment, but it is not always possible to find what you need. That is why it is possible, which will not only cost less and have the required dimensions, but also fit the style of the interior. The easiest way is to make a chair based on chipboard. If the intention is not to produce chairs in bulk for sale, then it is impractical to purchase a whole sheet.  Drawing of a wooden chair. Among other materials, the work will require a soft edge in 18 mm, which has a U-shape. To fix it, you need the glue "Moment". As fasteners should use confirmats with dimensions of 5x70. You will also need self-tapping screws with dimensions - 4х16 mm. In the process of sawing, it is recommended to use a jigsaw that is equipped with clean saws for working on chipboard. The saws must be narrow, designed for the realization of figured cuts. At the base of the chair will lie a chipboard of 18 mm, from which it is necessary to cut out the blanks with the following dimensions, each of them must be prepared in an amount of 2 pieces:

Drawing of a wooden chair. Among other materials, the work will require a soft edge in 18 mm, which has a U-shape. To fix it, you need the glue "Moment". As fasteners should use confirmats with dimensions of 5x70. You will also need self-tapping screws with dimensions - 4х16 mm. In the process of sawing, it is recommended to use a jigsaw that is equipped with clean saws for working on chipboard. The saws must be narrow, designed for the realization of figured cuts. At the base of the chair will lie a chipboard of 18 mm, from which it is necessary to cut out the blanks with the following dimensions, each of them must be prepared in an amount of 2 pieces:

- 850х450 (for sidewalls);

- 500х450 (for the seat, the lower rim and the backrest).

This number of blanks will be necessary in order to make 1 chair with your own hands.

Tools and materials

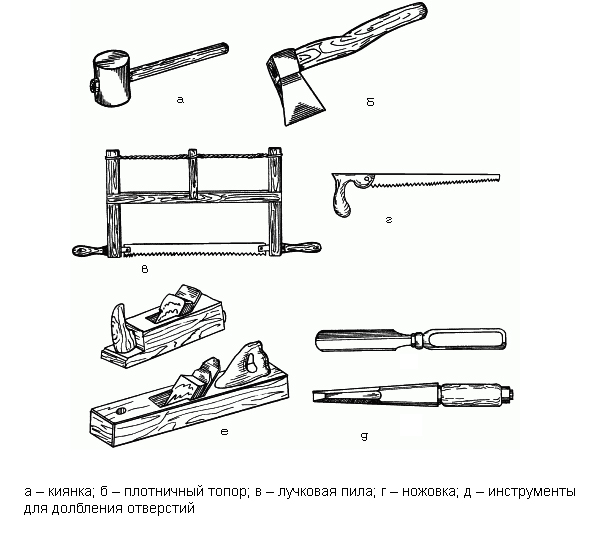

Tools for making wooden chairs.

Tools for making wooden chairs.

- edging;

- glue;

- Chipboard;

- confirmations;

- metal furniture corners;

- self-tapping screws;

- a jigsaw;

- drill-screwdriver;

- roulette;

- pencil;

- construction right angle;

- primer.

Back to contents</a>

Preparatory work

The most interesting in the model of the chairis that you can choose the design of the sidewalls, which are also legs. To do this, they have to be depicted by hand, giving any form. Then you can start sawing the elements with a jig saw. For the sidewalls to be the same, you must first cut out one of them, using it as a template for preparing the other. In the process of sawing, do not be afraid of the fact that chipped on the butt-ends may appear, since the edge announces them.  Scheme of assembling a wooden chair. Making a chair with your own hands, you should observe the following dimensions: the height of the seat from the floor surface is within 420-450 mm, the backrest inclination is 10 ° from the vertical, the step from the seat to the bottom of the back is 200 mm. From the bottom of the seat to the arch that forms the legs, the minimum should be 150 mm. At this distance, the lower karga will be installed. The legs must not be less than 100 mm wide. The seat inclination should be 5 ° from the horizontal. In this case, the slope should be back. You can make a chair with your own hands with such dimensions from plywood. However, its thickness should be equal to 16 or 18 mm, otherwise it will be necessary to process the ends, which is very troublesome. When using plywood as a material, you can make the legs thinner, since this material is more durable. The width of the seat, the yoke and the backrest must be 500 mm. Curvatures of the above elements can be drawn according to the traditional hula-hoop. One piece should be used to make the seat, the other will form the backbone and lower the rim. The 1st will have a width of 260 mm (in the wide part), the second will have 145 mm at the edges. Back to contents</a>

Scheme of assembling a wooden chair. Making a chair with your own hands, you should observe the following dimensions: the height of the seat from the floor surface is within 420-450 mm, the backrest inclination is 10 ° from the vertical, the step from the seat to the bottom of the back is 200 mm. From the bottom of the seat to the arch that forms the legs, the minimum should be 150 mm. At this distance, the lower karga will be installed. The legs must not be less than 100 mm wide. The seat inclination should be 5 ° from the horizontal. In this case, the slope should be back. You can make a chair with your own hands with such dimensions from plywood. However, its thickness should be equal to 16 or 18 mm, otherwise it will be necessary to process the ends, which is very troublesome. When using plywood as a material, you can make the legs thinner, since this material is more durable. The width of the seat, the yoke and the backrest must be 500 mm. Curvatures of the above elements can be drawn according to the traditional hula-hoop. One piece should be used to make the seat, the other will form the backbone and lower the rim. The 1st will have a width of 260 mm (in the wide part), the second will have 145 mm at the edges. Back to contents</a>

The process of manufacturing a chair

Picture 1. Folding chair is a very convenient part of the interior, as it is convenient to transport and store. In the sidewalls need to equip the through holes, the diameter of each of which should be equal to 8 mm. These holes will be required for the installation of confirmations. It is more convenient to make a marking of 1 sidewall, and on the 2nd to make holes on the 1st, this will ensure complete coincidence of the elements. At the ends of the inner blanks, it is necessary to drill holes with a diameter of 5 mm, while the minimum depth is 60 mm. The construction should be tightened to confirmations, fixing the seat from below with the help of corners. If the width of the structure is 500 mm too small, a larger number of corners can be installed from below. Before snapping the edge, the ends of the elements should be primed. As the most suitable composition will emulsify, which should not be confused with the traditional clerical glue PVA. As soon as the emulsion dries, the "Moment" glue must be applied along the axis of the butt and the edge is snapped. In this case, the structure must be laid on its side. The edge of the edge will not be visible at the top of the arch. Laminated chipboard has many advantages and disadvantages, but its use eliminates the need for paintwork and other processing operations after the construction. This chair will last a long time if it is not subjected to excessive mechanical stress and moisture. Back to contents</a>

Picture 1. Folding chair is a very convenient part of the interior, as it is convenient to transport and store. In the sidewalls need to equip the through holes, the diameter of each of which should be equal to 8 mm. These holes will be required for the installation of confirmations. It is more convenient to make a marking of 1 sidewall, and on the 2nd to make holes on the 1st, this will ensure complete coincidence of the elements. At the ends of the inner blanks, it is necessary to drill holes with a diameter of 5 mm, while the minimum depth is 60 mm. The construction should be tightened to confirmations, fixing the seat from below with the help of corners. If the width of the structure is 500 mm too small, a larger number of corners can be installed from below. Before snapping the edge, the ends of the elements should be primed. As the most suitable composition will emulsify, which should not be confused with the traditional clerical glue PVA. As soon as the emulsion dries, the "Moment" glue must be applied along the axis of the butt and the edge is snapped. In this case, the structure must be laid on its side. The edge of the edge will not be visible at the top of the arch. Laminated chipboard has many advantages and disadvantages, but its use eliminates the need for paintwork and other processing operations after the construction. This chair will last a long time if it is not subjected to excessive mechanical stress and moisture. Back to contents</a>

Technology of manufacturing stool

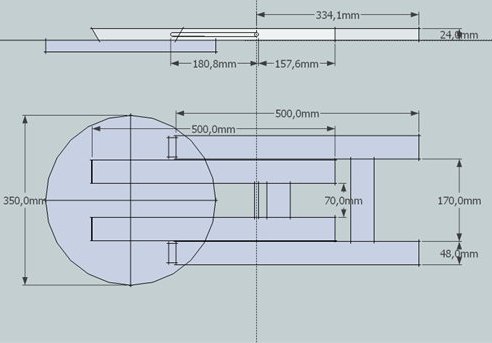

Figure 2. Scheme of dimensions and elements of a folding stool. The stool is no less useful in the household than the stool. You can make it yourself. And it can look like it is shown in Fig. 1. For the works you will need:

Figure 2. Scheme of dimensions and elements of a folding stool. The stool is no less useful in the household than the stool. You can make it yourself. And it can look like it is shown in Fig. 1. For the works you will need:

- manual frezer;

- electric jigsaw;

- Screwdriver;

- grinding machine;

- Clamps;

- roulette;

- pencil.

Material for the construction can be furnitureshield. In Fig. 2 you can see the diagram with the dimensions of the elements. The legs in the upper part should be sawed, giving them an angle of 30 °. The bridges located between the legs must be installed by means of dowels mounted on the glue. All adjacent surfaces must be carefully treated with glue, a drop of which must fall and into the holes intended for the installation of dowels. The components of the legs need to be pulled off by means of clamps and leave, until the glue dries, from its surpluses it will be necessary to get rid of. Folding stool should be mounted, observing the dimensions that are indicated on the diagram. This will eliminate the occurrence of problems with the described construction. The hinges are to be screwed using self-tapping screws with dimensions of 3.5x16 mm. The piece that remains from the shield can be used to prepare the tube that closes the middle of the hairpin. If in the arsenal of the master there is a small lathe, then this workpiece can be made with a circular section. However, you can do with a plane, which will make the tube multifaceted, it does not spoil the appearance of the element. It is not enough just to make a stool or chair with your own hands, it is important that it is also beautiful. To do this, you can make the color of the design even more intense, emphasizing the natural texture of the wood. To do this, the surface of the chair and all its elements must be treated with fine-grained emery paper (x300), as a final step it is possible to cover the surface of the construction with a toning varnish, having done this in at least 2 approaches. This will give you a comfortable and elegant piece of furniture. This stool can be used not only in the interior space, but also outside it, setting, for example, in the garden. In view of the fact that the described stool is folding, it easily fits in the trunk of the car. This will make it easy to transport it for a convenient pastime outside the city.