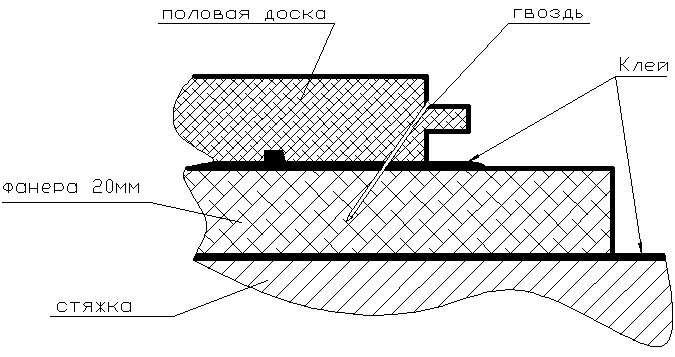

It is recommended to use natural materials for the floor.materials that are not only attractive, but also environmentally friendly, durable, resistant to heavy loads and abrasion. Solid wood boards have these properties, and they are distinguished by their elegant and solid appearance and extreme durability. Laying such boards is not difficult. The work is easier to cope with than laying traditional parquet. Although solid wood boards do not have the luxury of artistic parquet, their appearance is more solid. Most often, solid wood boards are laid on a screed, but not directly on a concrete base, but on joists or plywood covering. Instructions for .Why is it so? The board is subject to temperature deformations and negative impact of humidity, therefore it is not recommended to lay it directly on concrete. But a layer of moisture-resistant plywood or floors on logs provide the necessary qualities. In this way, it is possible to level the base, give it exactly those properties that are required by the installation technology. Such work involves additional costs, and more time is spent. If you lay the coating directly on the screed, you may encounter deformation of the boards, the formation of cracks, creaking and other negative factors.

Instructions for .Why is it so? The board is subject to temperature deformations and negative impact of humidity, therefore it is not recommended to lay it directly on concrete. But a layer of moisture-resistant plywood or floors on logs provide the necessary qualities. In this way, it is possible to level the base, give it exactly those properties that are required by the installation technology. Such work involves additional costs, and more time is spent. If you lay the coating directly on the screed, you may encounter deformation of the boards, the formation of cracks, creaking and other negative factors.

Hardboard options

Types of fastening parquet boards. completely different, you can choose the best option. There are many options for such installation:

Types of fastening parquet boards. completely different, you can choose the best option. There are many options for such installation:

Return to Contents</a>

Preparing the board for work

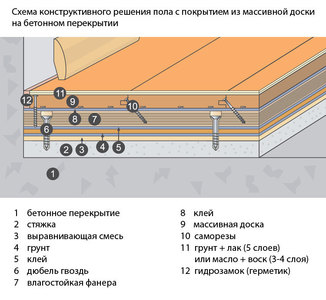

How to perform the work correctly?Preparation of the covering involves work with the base. Solid boards cannot be laid directly on a concrete base, the screed must be covered with a layer, and joists must be installed. Plywood is laid directly on the screed only when it is not possible to reduce the height of the ceiling. This is usually typical for city apartments. In this case, a layer of waterproofing is laid on the concrete, after which moisture-resistant plywood is laid. Joists are preferable, as they are more reliable, they perfectly protect the board from various negative phenomena, including deformation, cracking, drying out or swelling. Construction of a floor on logs. Floors on logs are made in this way:

Construction of a floor on logs. Floors on logs are made in this way:

Return to Contents</a>

Laying a massive board

Laying solid wood boards on a screed.After the joists are installed and the finished floor is sheathed, you can start laying the solid wood boards. You can use one of two methods - glue and the locking method. Before doing the work, you need to clean the floor, dry it, and check its horizontality. After that, the surface is additionally treated with a special mastic, which gives the base water-repellent properties. After that, the plywood should dry. The board is kept for about 4 days until the plywood dries. This should be done in the room where it will be installed. The material is stored horizontally, you can lay a film under it. When the floor has dried and the board has settled, you can start installing. A layer of glue is applied to the back of each board, after which it is tightly pressed to the base. The second board is covered with an adhesive composition. You need to snap the lock tightly, do this at an angle, and then press the board to the surface of the base. Laying solid wood boards continues in the same way until the entire floor is covered. First, whole boards are laid, then trimmed, and small pieces are laid. The glue-free method involves laying directly on the surface, but without glue. This is done for floors under joists, the space between which can be filled with insulation. Such a floor turns out to be floating, i.e. the solid board is not connected to the base at all. This method is the most preferable, but everything depends on external conditions. Fastening is carried out by means of a tongue-and-groove locking connection. The board is laid on the surface, after which the second is inserted into the groove at an angle and lowered onto the surface. The process itself is almost no different, but glue is not used. Return to contents</a>

Laying solid wood boards on a screed.After the joists are installed and the finished floor is sheathed, you can start laying the solid wood boards. You can use one of two methods - glue and the locking method. Before doing the work, you need to clean the floor, dry it, and check its horizontality. After that, the surface is additionally treated with a special mastic, which gives the base water-repellent properties. After that, the plywood should dry. The board is kept for about 4 days until the plywood dries. This should be done in the room where it will be installed. The material is stored horizontally, you can lay a film under it. When the floor has dried and the board has settled, you can start installing. A layer of glue is applied to the back of each board, after which it is tightly pressed to the base. The second board is covered with an adhesive composition. You need to snap the lock tightly, do this at an angle, and then press the board to the surface of the base. Laying solid wood boards continues in the same way until the entire floor is covered. First, whole boards are laid, then trimmed, and small pieces are laid. The glue-free method involves laying directly on the surface, but without glue. This is done for floors under joists, the space between which can be filled with insulation. Such a floor turns out to be floating, i.e. the solid board is not connected to the base at all. This method is the most preferable, but everything depends on external conditions. Fastening is carried out by means of a tongue-and-groove locking connection. The board is laid on the surface, after which the second is inserted into the groove at an angle and lowered onto the surface. The process itself is almost no different, but glue is not used. Return to contents</a>

Finishing Coating

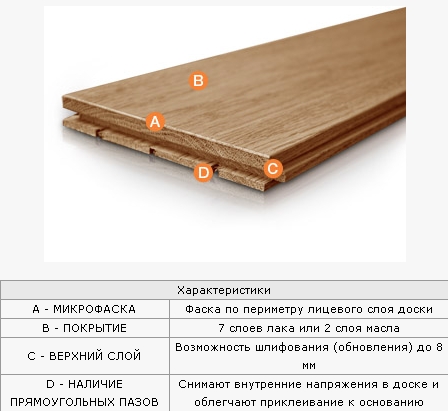

Characteristics of solid wood boards.After the laying of the solid board is finished, it is necessary to proceed to the finishing work. To do this, the surface is processed with a grinding machine, all dust is removed from the surface. Further work may consist of covering the boards with a layer of varnish, painting them or impregnating them with special oils. It all depends on what exactly is required from the coating. After the varnish dries, a beautiful, glossy or matte coating is obtained. The varnish is applied in 2-3 layers, each of them must dry completely. The varnish itself can be transparent or tinted. It all depends on the wood, the presence of a beautiful natural pattern on it. Before varnishing the surface, you can use a stain. This composition can give the wood any desired shade. It perfectly protects wood from various negative effects. For example, from moisture, insects, rot. The stain is applied with a brush or roller, 1-2 layers are enough, but it all depends on what effect is needed. After complete drying, you can start varnishing, two layers are enough. Solid wood boards can also be impregnated with special oil. This option is the most preferable, as the wood acquires a noble appearance. The cost of oils is usually quite significant, varnishing is cheaper. You need to start finishing about a day after the coating is completely ready. The consumption of varnish is about 150 g per 1 m², but everything depends on the composition, you need to pay attention to it. You can walk on the floor after 2 days, and more serious loads are possible no earlier than in a week. Solid wood boards are distinguished by a stylish and solid appearance, which will give the room a certain charm. Laying such a floor covering is not so difficult, most often it is mounted on logs. This provides the necessary conditions for the wood, protects it from moisture, sudden temperature changes and expansion.

Characteristics of solid wood boards.After the laying of the solid board is finished, it is necessary to proceed to the finishing work. To do this, the surface is processed with a grinding machine, all dust is removed from the surface. Further work may consist of covering the boards with a layer of varnish, painting them or impregnating them with special oils. It all depends on what exactly is required from the coating. After the varnish dries, a beautiful, glossy or matte coating is obtained. The varnish is applied in 2-3 layers, each of them must dry completely. The varnish itself can be transparent or tinted. It all depends on the wood, the presence of a beautiful natural pattern on it. Before varnishing the surface, you can use a stain. This composition can give the wood any desired shade. It perfectly protects wood from various negative effects. For example, from moisture, insects, rot. The stain is applied with a brush or roller, 1-2 layers are enough, but it all depends on what effect is needed. After complete drying, you can start varnishing, two layers are enough. Solid wood boards can also be impregnated with special oil. This option is the most preferable, as the wood acquires a noble appearance. The cost of oils is usually quite significant, varnishing is cheaper. You need to start finishing about a day after the coating is completely ready. The consumption of varnish is about 150 g per 1 m², but everything depends on the composition, you need to pay attention to it. You can walk on the floor after 2 days, and more serious loads are possible no earlier than in a week. Solid wood boards are distinguished by a stylish and solid appearance, which will give the room a certain charm. Laying such a floor covering is not so difficult, most often it is mounted on logs. This provides the necessary conditions for the wood, protects it from moisture, sudden temperature changes and expansion.