Laying the floor on joists is done independently. The ease of installation and a number of advantages make this material indispensable for laying on the floor surface. What determines the popularity of joists? Installation of plywood floor on joists.Firstly, the load on the floor (structure or floor) is distributed evenly along the entire perimeter. Secondly, laying the floor with joists means providing the interior of the apartment with heat and sound insulation properties.

Installation of plywood floor on joists.Firstly, the load on the floor (structure or floor) is distributed evenly along the entire perimeter. Secondly, laying the floor with joists means providing the interior of the apartment with heat and sound insulation properties.

Some advantages

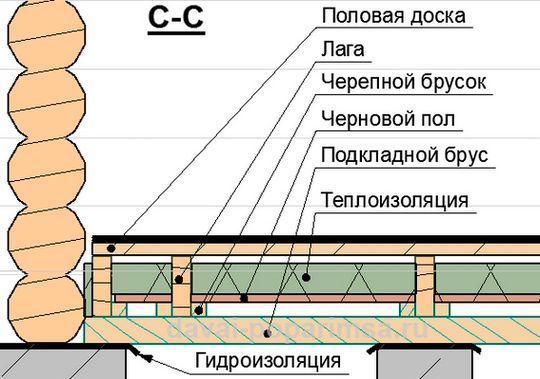

Scheme of installation of logs. Laying the floor on logs has the following technical features:

Scheme of installation of logs. Laying the floor on logs has the following technical features:

What is lag?These are beams made of wood or polymer, which are laid on the finishing coating. The versatility of such a beam is due to the fact that it can be mounted on a wooden, reinforced concrete and earthen base. What are the logs made of? A log is a beam that is made of metal, wood, plastic, reinforced concrete. However, wooden ones are especially popular. Return to contents</a>

Construction and installation of logs

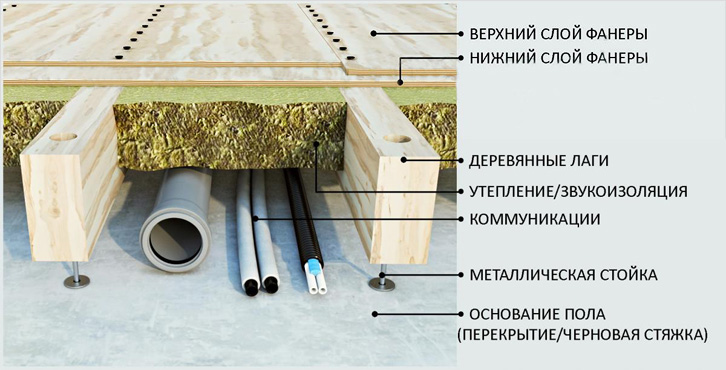

Installation of a floor using joists.If the surface is made of wood, it will be difficult to achieve a smooth surface. To get the smoothest possible floor, you should attach the floor beams to the side beams. Using this method does not require a special lining that regulates the height of the beams. The joists must be fastened with screws that should be 2.5 times longer than the width of the beam with a diameter of at least 6 mm. To avoid cracks in the wood, experts recommend making a hole in the beam and joist with a diameter 2.5 mm smaller than the diameter of the screw. With a large distance between the beams, repeated laying is required, which is perpendicular to the first masonry. However, the distance should be smaller. Another option is to use thicker boards intended for finishing. If you have concrete floors, then the floor structure on the joists looks completely different:

Installation of a floor using joists.If the surface is made of wood, it will be difficult to achieve a smooth surface. To get the smoothest possible floor, you should attach the floor beams to the side beams. Using this method does not require a special lining that regulates the height of the beams. The joists must be fastened with screws that should be 2.5 times longer than the width of the beam with a diameter of at least 6 mm. To avoid cracks in the wood, experts recommend making a hole in the beam and joist with a diameter 2.5 mm smaller than the diameter of the screw. With a large distance between the beams, repeated laying is required, which is perpendicular to the first masonry. However, the distance should be smaller. Another option is to use thicker boards intended for finishing. If you have concrete floors, then the floor structure on the joists looks completely different:

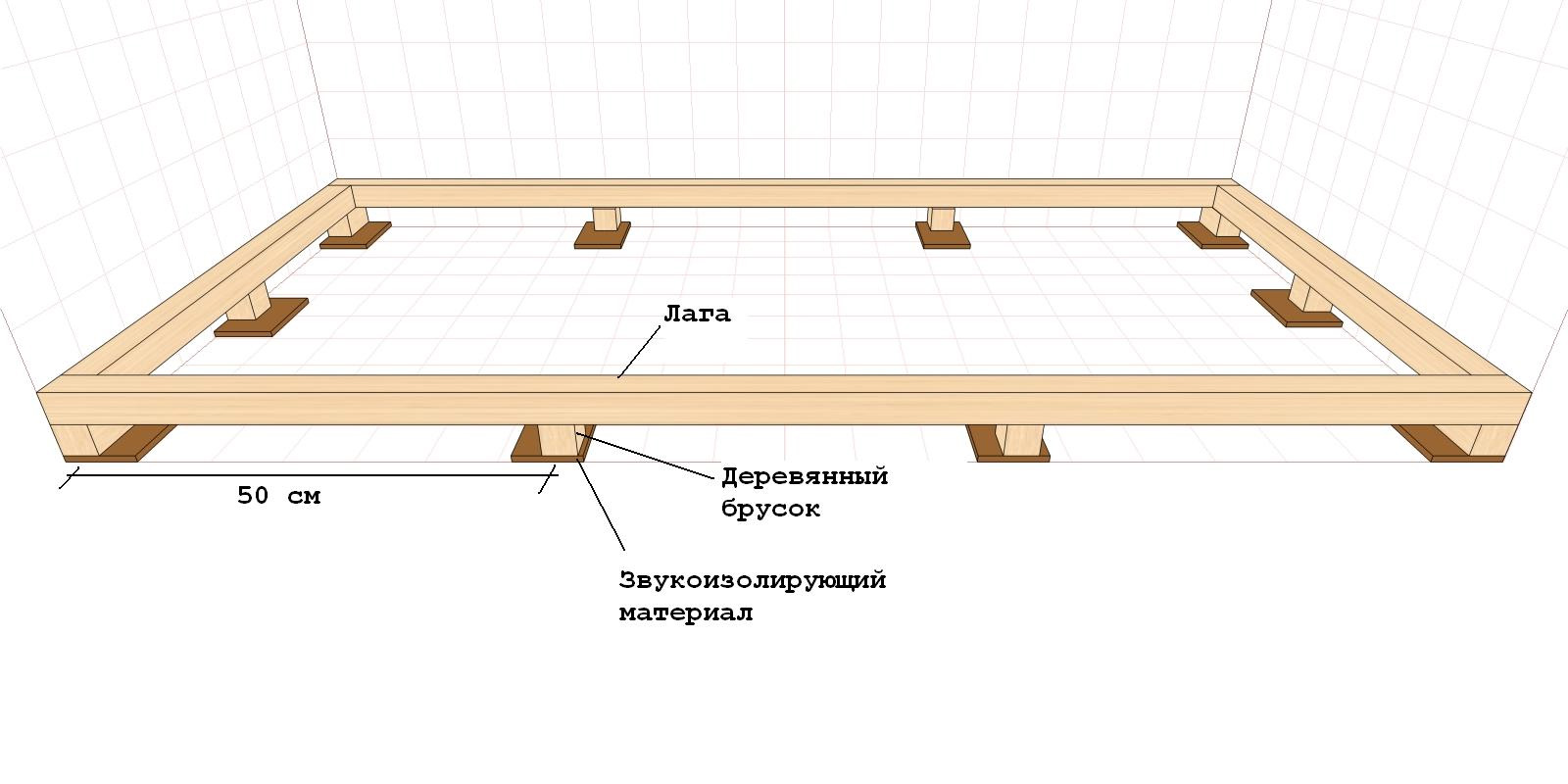

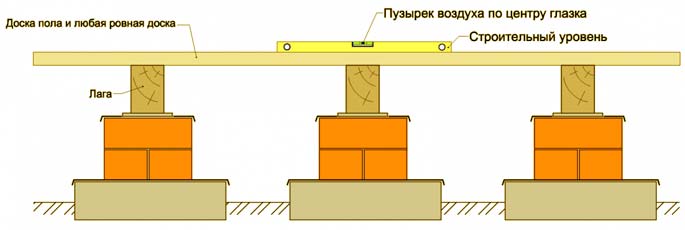

Installing the logs and checking the horizontality beforelaying the floor. For such work, you need boards at least 2 m long. If this length is not enough, then you can join the parts end to end. When connecting the joists, you should take into account one important circumstance: the joints of adjacent boards should be offset relative to each other by half a meter. The beams can be laid either on a screed or on waterproofing. Otherwise, the joist will absorb moisture, which will reduce its service life. It is not recommended to lay joists on soft insulation. Gradually, you will notice how the floor will deteriorate, spoiling the finished floor. When installing thermal insulation, you can use boards of a certain width, but the beams must be located strictly between them. In any other case, the work will be in vain and will not bring the desired result. If the insulation is longer than the beams, then select the location of the joists so that the distance between them can be filled with scraps. This is a very economical solution, since you do not have to buy additional joists. If you want to lay the timber on an earthen base, you should prepare the surface. First, remove the turf, then scatter 5 cm of gravel over the surface. The final stage will be pouring 5 cm of concrete on the floor. After that, lay the waterproofing, screed, and insulation. In addition, if you are working with an earthen base, the screed and insulation can be replaced with polystyrene concrete.

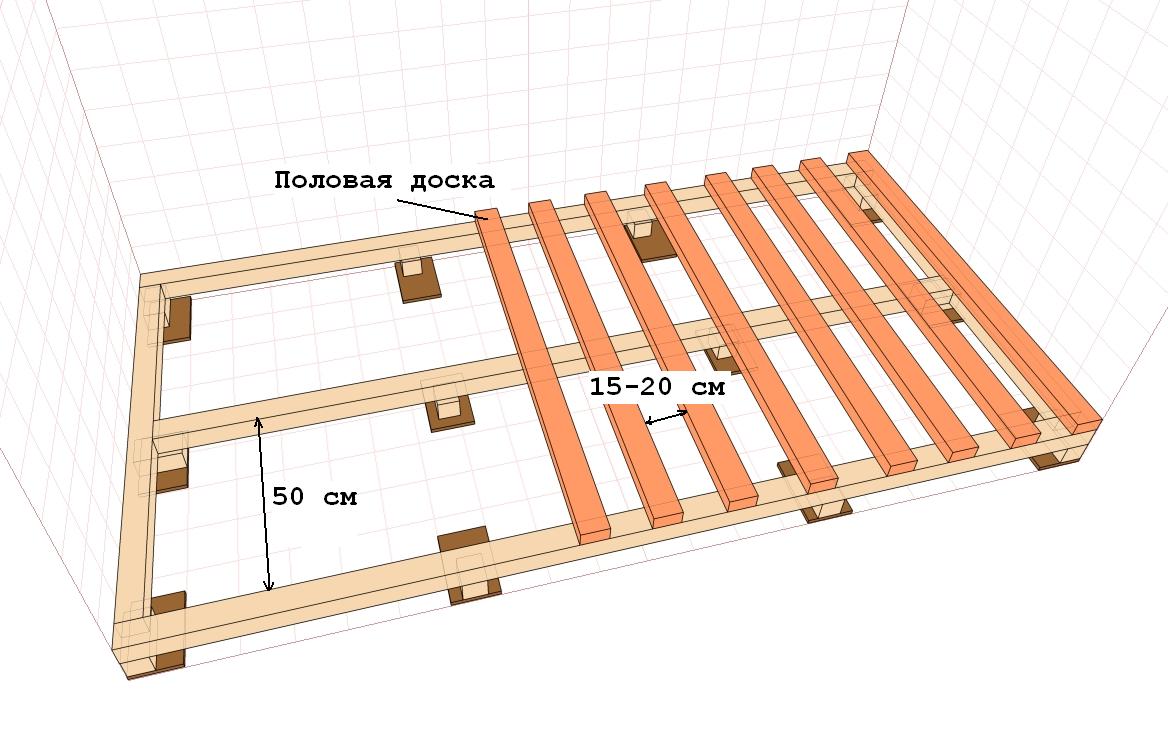

Installing the logs and checking the horizontality beforelaying the floor. For such work, you need boards at least 2 m long. If this length is not enough, then you can join the parts end to end. When connecting the joists, you should take into account one important circumstance: the joints of adjacent boards should be offset relative to each other by half a meter. The beams can be laid either on a screed or on waterproofing. Otherwise, the joist will absorb moisture, which will reduce its service life. It is not recommended to lay joists on soft insulation. Gradually, you will notice how the floor will deteriorate, spoiling the finished floor. When installing thermal insulation, you can use boards of a certain width, but the beams must be located strictly between them. In any other case, the work will be in vain and will not bring the desired result. If the insulation is longer than the beams, then select the location of the joists so that the distance between them can be filled with scraps. This is a very economical solution, since you do not have to buy additional joists. If you want to lay the timber on an earthen base, you should prepare the surface. First, remove the turf, then scatter 5 cm of gravel over the surface. The final stage will be pouring 5 cm of concrete on the floor. After that, lay the waterproofing, screed, and insulation. In addition, if you are working with an earthen base, the screed and insulation can be replaced with polystyrene concrete. Distance between floor joists. Now about the distance between joists. It should be no more than 40 cm so that the load is evenly distributed on the floors. Tips for proper laying of joists:

Distance between floor joists. Now about the distance between joists. It should be no more than 40 cm so that the load is evenly distributed on the floors. Tips for proper laying of joists:

Return to Contents</a>

How to lay the floor: step by step instructions

Чтобы сделать самостоятельно полы лагами, it is necessary to develop a plan. In the plan, you can indicate the parameters of the beams, all sorts of preparatory work and devices that will be useful during the installation process. Tools required for work: hammer drill, drill, socket wrench, hammer, jigsaw, axe. You will need:

Tools required for work: hammer drill, drill, socket wrench, hammer, jigsaw, axe. You will need:

The beams are laid on a pre-calculatedthe gap between them for sound insulation. You should use a level to achieve the most even surface. If the surface is concrete, then anchor bolts are used to secure the joists. If the base is made of some other material, then dowels are used. What are the advantages of a wooden joist? The technical properties of the beams are determined by their strength, reliability, and ecology. The joist does not require any additional care. In addition, floors on joists have a presentable appearance. The advantages of the joist include:

- It is not necessary to exert efforts to make the floor even;

- bars have thermal insulation properties;

- installation is done quickly, in several stages;

- excellent sound insulation;

- the possibility of the location of communications.

Return to Contents</a>Laying thermal insulation As already describedpreviously, the joists are mounted at a certain pitch. Insulation (superfine basalt fiber or polystyrene foam) is placed in the remaining gaps. You can use roll insulation for these purposes. In addition, expanded clay can be used for the insulating layer. Return to contents</a>Laying of clean ceiling Laying boards on joists.Laying the wooden log starts from the corner of the room. The first row is tongue-and-groove relative to the wall, while the gap between the wall and the log should be no more than 1 cm, since deformation of the wood under the influence of the environment is possible. Next, a row of logs is laid offset relative to the first row by approximately several beams. In order for the boards to be firmly fixed to the base, it is necessary to lightly tap on the wood with a construction hammer, which is adjacent to the end of the beam. Attach the boards along the wall, fix them with screws. They can be on the surface, but no one will see these details - the baseboards will hide all the flaws. Thus, all the deformed boards are covered with this decorative element. Unevenness will also not be visible. However, this does not mean that you do not need to follow the instructions, over time, if laid incorrectly, the structure collapses. Return to the table of contents</a>Leveling the floor with your own hands

Laying boards on joists.Laying the wooden log starts from the corner of the room. The first row is tongue-and-groove relative to the wall, while the gap between the wall and the log should be no more than 1 cm, since deformation of the wood under the influence of the environment is possible. Next, a row of logs is laid offset relative to the first row by approximately several beams. In order for the boards to be firmly fixed to the base, it is necessary to lightly tap on the wood with a construction hammer, which is adjacent to the end of the beam. Attach the boards along the wall, fix them with screws. They can be on the surface, but no one will see these details - the baseboards will hide all the flaws. Thus, all the deformed boards are covered with this decorative element. Unevenness will also not be visible. However, this does not mean that you do not need to follow the instructions, over time, if laid incorrectly, the structure collapses. Return to the table of contents</a>Leveling the floor with your own hands Chipboard floor on joists.Surely you have encountered such a problem. It is especially common in old houses, where the height may exceed the evenness limits by up to 20 cm. Concrete screed is not always a solution: the building may not withstand such a load. Here it would be reasonable to use adjustable lags. The process of their installation is carried out according to the following scheme:

Chipboard floor on joists.Surely you have encountered such a problem. It is especially common in old houses, where the height may exceed the evenness limits by up to 20 cm. Concrete screed is not always a solution: the building may not withstand such a load. Here it would be reasonable to use adjustable lags. The process of their installation is carried out according to the following scheme:

Return to Contents</a>Finishing works Subfloor on joists with your own hands.Now that the main work is done, you can begin to finish laying the joists. Your task is to get rid of any unevenness on the surface and eliminate roughness. A sanding or grinding machine is ideal for this type of work. You start the process with sandpaper, which will effectively and quickly remove all excess. Then you should take sandpaper, which will polish the surface of the base. To increase the service life and wear resistance of such a floor, you need to cover it with one of 3 types of impregnations:

Subfloor on joists with your own hands.Now that the main work is done, you can begin to finish laying the joists. Your task is to get rid of any unevenness on the surface and eliminate roughness. A sanding or grinding machine is ideal for this type of work. You start the process with sandpaper, which will effectively and quickly remove all excess. Then you should take sandpaper, which will polish the surface of the base. To increase the service life and wear resistance of such a floor, you need to cover it with one of 3 types of impregnations:

You have read the material on laying the log,all that's left is to get to work. Such floors will please you with their thermal insulation properties, durability and long service life. You will be able to achieve a good result if you strictly follow the installation scheme. Despite the simplicity of the work, laying has its own characteristics and nuances. Today, craftsmen prefer to lay floors with logs, and for good reason - they will create a more impeccable appearance in your home.