Glass as a material for use inin apartment renovations has long been widespread. These can be combined structures or individual interior glass solutions. What can be made from such a seemingly fragile material? It is used in the design of interior doors and partitions, the manufacture of lamps, shelves on the wall and for the closet, and so on. Such structures look very elegant and beautiful, but another important factor is their functionality. For example, shelves made of glass participate in the interior design and at the same time are not inferior in their functionality to other materials. Glass shelves will add lightness andweightlessness, unlike conventional wooden ones. Basically, glass can be used in any room, which is important. Therefore, further we will talk specifically about glass shelves. More precisely, about how to make them correctly, hang them and illuminate them. DIY LED lighting of glass shelves is available to everyone.

Glass shelves will add lightness andweightlessness, unlike conventional wooden ones. Basically, glass can be used in any room, which is important. Therefore, further we will talk specifically about glass shelves. More precisely, about how to make them correctly, hang them and illuminate them. DIY LED lighting of glass shelves is available to everyone.

Work on cutting glass and its further processing

If you have decided that your interior will includethere are shelves made of glass, then it's time to think about how to make them correctly. There are two possible solutions. This is custom manufacturing in a special company or independent work. Do you want to save money or just learn how to work with glass material? Then the following information will be useful to you. You will need:

- good quality glass cutter;

- a belt type grinder, the grain size of the skin used for the work should correspond to a value of 120 units;

- ruler.

LED backlighting can last up to100,000 hours of continuous operation. In order for the work to be enjoyable, you will need, as noted above, a ruler and strong hands. It is not about strength, but about confidence. For ease of cutting glass, it is best to purchase an oil glass cutter. And if you are going to cut glass for the first time, it is better to practice a little. Please note that experts do not advise making a second cut of the glass, since this way you will scratch the glass. One time is enough, after which it must be broken along the intended line. So, in addition to cutting, an important factor is the processing of glass cuts. This is a necessary condition, since during operation and work it is very easy to cut yourself on its sharp edge. In addition to safety, processing will give an aesthetic appearance to the glass product. As already mentioned above, a belt grinder is usually used for these purposes. But if you do not have one, then you can perform this procedure manually. Just be prepared that it will take quite a lot of time. When grinding glass, the surface to be treated must be wetted with water. As a result of these actions, you will prevent the spread of glass dust in the atmosphere of the room. This is necessary, since such dust is very harmful to human health. Be sure to use personal protective equipment, such as a respirator. And using water when grinding allows you to ultimately obtain a transparent edge surface. If grinding is carried out without water, the edge will remain matte. Return to the table of contents</a>

LED backlighting can last up to100,000 hours of continuous operation. In order for the work to be enjoyable, you will need, as noted above, a ruler and strong hands. It is not about strength, but about confidence. For ease of cutting glass, it is best to purchase an oil glass cutter. And if you are going to cut glass for the first time, it is better to practice a little. Please note that experts do not advise making a second cut of the glass, since this way you will scratch the glass. One time is enough, after which it must be broken along the intended line. So, in addition to cutting, an important factor is the processing of glass cuts. This is a necessary condition, since during operation and work it is very easy to cut yourself on its sharp edge. In addition to safety, processing will give an aesthetic appearance to the glass product. As already mentioned above, a belt grinder is usually used for these purposes. But if you do not have one, then you can perform this procedure manually. Just be prepared that it will take quite a lot of time. When grinding glass, the surface to be treated must be wetted with water. As a result of these actions, you will prevent the spread of glass dust in the atmosphere of the room. This is necessary, since such dust is very harmful to human health. Be sure to use personal protective equipment, such as a respirator. And using water when grinding allows you to ultimately obtain a transparent edge surface. If grinding is carried out without water, the edge will remain matte. Return to the table of contents</a>

Glass shelf fixing

The aluminum profile must be exactlymatch the thickness of the shelf, then it will be almost invisible. In order for your glass shelf to be located on the wall securely and beautifully, you can use one of two options. The first involves the use of special holders, the second is based on the use of an aluminum profile. You can give preference to one or another method only based on your own wishes, since the only difference is how the glass will be installed. Using holders is a universal option. They are suitable for glass of any size (thickness). But an aluminum profile does not have this quality, since it has a specific purpose. The advantage of using a profile is the ability to equip such a shelf with LED lighting, which is tucked into it and emits light as if from inside the structure. But more on that later. Shelf holders have a fairly simple installation method. Its design has two parts: a base that will be mounted on the wall, and an upper part, which is decorative. In the process of work, they are separated, and the base is fixed to the wall. To do this, you need to use a level and dowels, which usually come with the holder. The minimum number of holders per shelf is 2 pcs. But depending on the size of your shelf, their number may increase. Return to contents</a>

The aluminum profile must be exactlymatch the thickness of the shelf, then it will be almost invisible. In order for your glass shelf to be located on the wall securely and beautifully, you can use one of two options. The first involves the use of special holders, the second is based on the use of an aluminum profile. You can give preference to one or another method only based on your own wishes, since the only difference is how the glass will be installed. Using holders is a universal option. They are suitable for glass of any size (thickness). But an aluminum profile does not have this quality, since it has a specific purpose. The advantage of using a profile is the ability to equip such a shelf with LED lighting, which is tucked into it and emits light as if from inside the structure. But more on that later. Shelf holders have a fairly simple installation method. Its design has two parts: a base that will be mounted on the wall, and an upper part, which is decorative. In the process of work, they are separated, and the base is fixed to the wall. To do this, you need to use a level and dowels, which usually come with the holder. The minimum number of holders per shelf is 2 pcs. But depending on the size of your shelf, their number may increase. Return to contents</a>

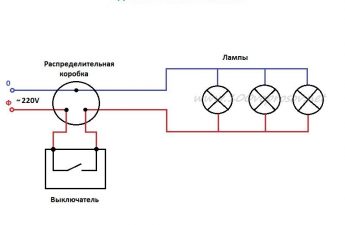

LED illumination of glass shelves: a device with your own hands

If there are a lot of shelves, then for each of them you canmake the backlight of a different color. As it became clear from the information given above, to make shelves with backlighting, you will need an aluminum profile for fastening. The order of work on the manufacture of LED backlighting. First, you need to go to the store and buy the profile mentioned above. The main thing is that it corresponds to the thickness of the glass from which you make the shelf. Next, it is cut to the required size. Do not forget that all burrs that appeared during the cutting process must be carefully removed. Now you need to perform high-quality fixation of the profile on the wall. For these purposes, holes are made in the profile for fastening. The profile must be fastened to the wall surface using self-tapping screws and special plastic plugs. It is important, when marking and fastening the shelf to the wall, not to forget to use a building level. The next stage involves installation work with a diode strip. Almost any profile has an insert made of plastic. Remember that you do not need to remove it. Such a device will protect the tape from possible contact with the aluminum surface. This will save you from possible short circuits. Be prepared for the fact that the installation of LED backlighting for a glass shelf, performed using an LED strip, will be labor-intensive, since its insertion into the profile causes a lot of inconvenience, especially if there is no free access to its end ends. With open ends, it is not very difficult to insert the strip, since the existing groove is intended specifically for this purpose. In another situation, various improvised devices can be used to place the strip inside the profile. One of the options for placing the strip inside the profile involves bending it like a "house". Just do not forget that you will then have to use a ruler for alignment. The ruler can be made of wood or plastic. At the last stage, a glass shelf with backlighting already placed inside the profile requires glass installation. The process is not complicated, but you will need to apply some effort. Since for reliability, the glass is located tightly in the profile. If you cannot do it yourself, then you can use a wooden extension and a rubber hammer. Now you are convinced that making glass shelves with LED lighting is quite easy and fast. But if you have come to the conclusion that this is a very difficult task for you, then the most correct thing would be to contact a workshop.

If there are a lot of shelves, then for each of them you canmake the backlight of a different color. As it became clear from the information given above, to make shelves with backlighting, you will need an aluminum profile for fastening. The order of work on the manufacture of LED backlighting. First, you need to go to the store and buy the profile mentioned above. The main thing is that it corresponds to the thickness of the glass from which you make the shelf. Next, it is cut to the required size. Do not forget that all burrs that appeared during the cutting process must be carefully removed. Now you need to perform high-quality fixation of the profile on the wall. For these purposes, holes are made in the profile for fastening. The profile must be fastened to the wall surface using self-tapping screws and special plastic plugs. It is important, when marking and fastening the shelf to the wall, not to forget to use a building level. The next stage involves installation work with a diode strip. Almost any profile has an insert made of plastic. Remember that you do not need to remove it. Such a device will protect the tape from possible contact with the aluminum surface. This will save you from possible short circuits. Be prepared for the fact that the installation of LED backlighting for a glass shelf, performed using an LED strip, will be labor-intensive, since its insertion into the profile causes a lot of inconvenience, especially if there is no free access to its end ends. With open ends, it is not very difficult to insert the strip, since the existing groove is intended specifically for this purpose. In another situation, various improvised devices can be used to place the strip inside the profile. One of the options for placing the strip inside the profile involves bending it like a "house". Just do not forget that you will then have to use a ruler for alignment. The ruler can be made of wood or plastic. At the last stage, a glass shelf with backlighting already placed inside the profile requires glass installation. The process is not complicated, but you will need to apply some effort. Since for reliability, the glass is located tightly in the profile. If you cannot do it yourself, then you can use a wooden extension and a rubber hammer. Now you are convinced that making glass shelves with LED lighting is quite easy and fast. But if you have come to the conclusion that this is a very difficult task for you, then the most correct thing would be to contact a workshop.