After installing the stretch ceiling between the canvasand the wall always leaves a small gap. Since the lightweight ceiling material is subject to slight fluctuations due to drafts, this gap does not always look neat. To complete the design of the room, the gap must be masked with something around the entire perimeter of the room. The best option for this is a decorative ceiling plinth, which will harmonize with the ceiling material, wallpaper, and the entire furnishings of the room. Decorative ceiling plinth is idealto mask cracks at the junction of the wall and the suspended ceiling. As a rule, the installation of dumbbell-shaped moldings (elements that will make up the frame) does not cause any particular difficulties. The most difficult thing is to provide high-quality finishing of the places where they are connected in the corners. This can be done manually, by specially treating the connected areas, or using ready-made corners. They must be included in the same batch of materials as the main elements. Of course, you cannot glue the skirting board to the suspended ceiling, since this can lead to irreparable damage to the expensive ceiling covering. Fastening is carried out exclusively to the walls.

Decorative ceiling plinth is idealto mask cracks at the junction of the wall and the suspended ceiling. As a rule, the installation of dumbbell-shaped moldings (elements that will make up the frame) does not cause any particular difficulties. The most difficult thing is to provide high-quality finishing of the places where they are connected in the corners. This can be done manually, by specially treating the connected areas, or using ready-made corners. They must be included in the same batch of materials as the main elements. Of course, you cannot glue the skirting board to the suspended ceiling, since this can lead to irreparable damage to the expensive ceiling covering. Fastening is carried out exclusively to the walls.

Varieties of material and tools for its installation

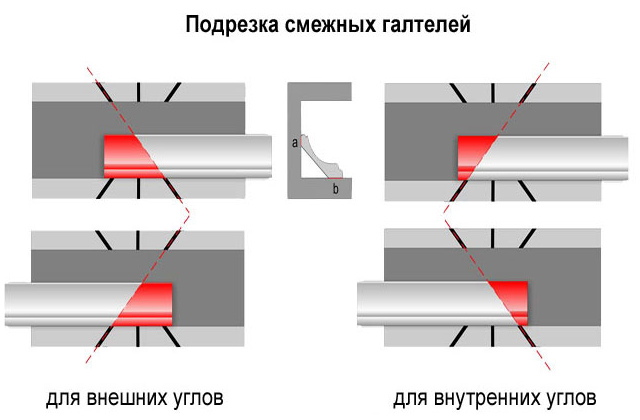

Trimming adjacent fillets using a miter box.Most often, skirting boards are made of foam plastic, polystyrene or polyurethane. The main advantages of foam plastic products include their low cost and light weight, thanks to which you can glue parts even over wallpaper. But this material is inflexible and quite fragile, so it is not suitable for rooms with a complex perimeter. Many types of glue cannot be used when working with it, as they dissolve foam plastic. If you glue a polyurethane skirting board to wallpaper, due to the heavy weight of the latter, both may break off and fall down at some point. Therefore, it is better to fasten it before the final wall covering is done. Polyurethane parts will be quite expensive, but the material is very resistant to chemical influences. Due to this, when choosing glue, there are no such restrictions as in the case of foam plastic. Molding (overhead decorative strip) is used for both suspended and stretch ceilings, but it is usually used only in rooms with perfectly flat walls and joints between them. Wooden frames finished in gold or precious wood look very impressive, but they are not glued, but mounted using special fasteners. But for adhesive fastening, it is best to choose products with a fairly wide vertical part to ensure the necessary strength of fixation of the elements due to the large adhesion area. Before work, you need to stock up on the following materials and tools:

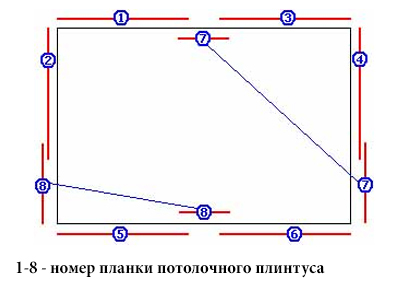

Trimming adjacent fillets using a miter box.Most often, skirting boards are made of foam plastic, polystyrene or polyurethane. The main advantages of foam plastic products include their low cost and light weight, thanks to which you can glue parts even over wallpaper. But this material is inflexible and quite fragile, so it is not suitable for rooms with a complex perimeter. Many types of glue cannot be used when working with it, as they dissolve foam plastic. If you glue a polyurethane skirting board to wallpaper, due to the heavy weight of the latter, both may break off and fall down at some point. Therefore, it is better to fasten it before the final wall covering is done. Polyurethane parts will be quite expensive, but the material is very resistant to chemical influences. Due to this, when choosing glue, there are no such restrictions as in the case of foam plastic. Molding (overhead decorative strip) is used for both suspended and stretch ceilings, but it is usually used only in rooms with perfectly flat walls and joints between them. Wooden frames finished in gold or precious wood look very impressive, but they are not glued, but mounted using special fasteners. But for adhesive fastening, it is best to choose products with a fairly wide vertical part to ensure the necessary strength of fixation of the elements due to the large adhesion area. Before work, you need to stock up on the following materials and tools: An example of calculating the required amount of ceiling plinth.

An example of calculating the required amount of ceiling plinth.

- folding meter or tape measure;

- pencil;

- cord for punching;

- mounting knife;

- stool or finished corners;

- putty knife;

- glue or putty;

- sealant (for sealing seams);

- clean rag;

- dumbbell-shaped mouldings 1.3 m long (for large rooms - up to 2 m);

- ladder.

When installing, it is best to use a special one,specially designed for ceiling plinths, glue. This will help to avoid unforeseen complications. The adhesive composition is selected colorless, but for white finishing material and glue can be used white. Good characteristics have compositions "Ogas", "Europlast", "Moment Montage", "Moment superstoykiy", "Titan". In order not to stain the ceiling, it is covered with cling film in advance. Return to the table of contents</a>

Technology and workflow

First of all, you need to do the markings.It is carried out along the bottom edge with a simple pencil or beaten with a cord. If the wallpaper has already been pasted and the baseboard is heavy, a cut is made along the marking line with a mounting knife, after which the strip of wallpaper above the cut is carefully removed. Installation begins from the corner of the room in which the finished corner is placed. If there is none, the fillet is placed in a miter box, and then one edge is cut at an angle of 45 ° with a sharp knife. The second part is done in a similar way, after which the prepared pieces are applied to the walls that form the corner, and it is checked how well they fit together. At least 10 cm of the part will be spent on cutting each of the corners, which must be taken into account when purchasing products. Glue is applied only to the end and the part of the baseboard that will subsequently be glued to the wall. Installation is carried out at a minimum distance from the ceiling. But if desired, you can increase the gap to 2 cm and place LED lighting in it. When installing, make sure that the frame does not touch the vinyl sheet, which is very sensitive to point damage. The parts are fixed sequentially, from one corner to another. There is another way: first glue the cut pieces at all corners, and then connect them in even sections. It is desirable that the length of the moldings forming the corner be at least 7 cm, for which sometimes it is necessary to shorten the other components a little. Using ready-made corner elements significantly simplifies the work. After applying the glue, it is necessary to hold it for the time specified in the instructions (from a few seconds to a few minutes), and then press the skirting board fragment to the wall strictly along the marking line. On uneven areas, the frame should be pressed as tightly as possible. For better fixation, you can use masking tape, which is removed only after the glue has completely dried. Its remnants, which protrude along the edges of the product, should be immediately wiped with a dry cloth, without waiting for them to harden. If putty was used as an adhesive, it can only be applied to a pre-moistened surface, cleared of wallpaper and paint. Any putty residue is removed with a damp cloth. Return to contents</a>

Correction of minor defects and final finishing

Despite the fact that flexible polyurethaneThe skirting board is able to repeat the contours of an uneven wall, as a result of which the assembled structure does not have noticeable cracks, as a result, it forms a not very neat line. Therefore, many installers achieve a tight fit of the molding to the wall only at the edges, and then seal the gap with silicone sealant. In some cases, it is also used as the main adhesive. The same sealant is used to fill the joints of parts. You can also use a special joint glue that provides a strong connection at the molecular level. Despite the fact that the range of polyurethane edging is now very diverse, some prefer to design according to their own preferences. In particular, the products can be painted in any color. However, painting the already glued skirting board is carried out only after the glue has completely dried and gained the required strength, that is, not earlier than in a day. If the installation was carried out by an inexperienced craftsman, cracks may sometimes appear at the joints of the moldings. Before starting repairs, you should wait until these cracks stop growing, and then completely clean them from the old glue with a saw. Then the cracks are filled with joint glue. During the hardening process, it forms foam, the excess of which must be periodically removed. The part of the hardened foam protruding above the surface is cut off with a knife, and then the joint is sanded with fine-grained sandpaper.