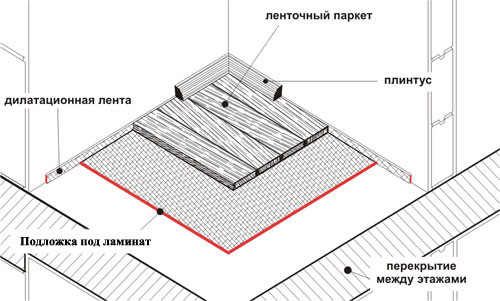

Any structure deteriorates with time. Its parts are also weakened. Especially it concerns floors, wooden and concrete. Exposed to constant loads, they are covered with cracks and potholes, wooden floorboards swell, concrete crumbles.  The scheme of the device of a floor And then you have to deal with the repair, because a complete replacement of the floor - this is often too troublesome, and expensive. Many are interested in how to level the floor without screed, since it is not always convenient to do it. There are several variants known, how to do without screed.

The scheme of the device of a floor And then you have to deal with the repair, because a complete replacement of the floor - this is often too troublesome, and expensive. Many are interested in how to level the floor without screed, since it is not always convenient to do it. There are several variants known, how to do without screed.

Necessary materials and tools

Necessary materials and tools. For work you need the following:

Necessary materials and tools. For work you need the following:

- sheet material (plywood, OSB boards);

- wooden beams;

- sand;

- a hacksaw for wood (metal);

- a hammer;

- pliers;

- Cylinder machine;

- perforator;

- building level;

- rule;

- measuring devices (ruler, angle, tape measure);

- nails, screws, dowels.

Back to contents</a>

How to level the floor of concrete with a sheet material?

The scheme of leveling the floor with sheet materials. Concrete floors, despite their known strength, may eventually lose their original evenness. This usually happens if, at the time of the flooring of such coatings, the technological installation rules were violated or when loading norms were not observed during their operation. As a result, such a floor acquires a not very flat appearance with rather large gaps and rather extensive potholes. In cases where the plans of the owner of the premises do not indicate a complete replacement of the foundation, experts recommend that it be trimmed with plywood slabs or OSB slabs. The preparatory part is reduced to puttying of small cracks and chips. Next comes the turn of podsypki in the formed depressions of sand. This point should not be ignored, since the used wood coating with time without a loose "prop" will surely sag, the floor will begin to "play" and creak. For podsypki use completely dry sand. This is the case with relatively minor defects. If on the repaired plane there are significant differences in altitude (deviations from the required level), then it is better to take a small granular mixture for this. In this case, it will not give a significant shrinkage.

The scheme of leveling the floor with sheet materials. Concrete floors, despite their known strength, may eventually lose their original evenness. This usually happens if, at the time of the flooring of such coatings, the technological installation rules were violated or when loading norms were not observed during their operation. As a result, such a floor acquires a not very flat appearance with rather large gaps and rather extensive potholes. In cases where the plans of the owner of the premises do not indicate a complete replacement of the foundation, experts recommend that it be trimmed with plywood slabs or OSB slabs. The preparatory part is reduced to puttying of small cracks and chips. Next comes the turn of podsypki in the formed depressions of sand. This point should not be ignored, since the used wood coating with time without a loose "prop" will surely sag, the floor will begin to "play" and creak. For podsypki use completely dry sand. This is the case with relatively minor defects. If on the repaired plane there are significant differences in altitude (deviations from the required level), then it is better to take a small granular mixture for this. In this case, it will not give a significant shrinkage.  Characteristics of plywood. With the help of the level, the required layer is corrected, which then is neatly leveled by the wide movements of the rule. Then comes the turn of the flooring of the sheet material. Correct laying involves the placement of plywood (OSB, gipsovoloknistyh panels) in two layers. And it is necessary to lay them out so that both layers are oriented in opposite directions. It should be noted that when laying the first, lower layer over the entire area of plywood sheets, it is necessary to tap with a rubber hammer. This action will finally and reliably set the plates on the padding. Then you can drill holes in the concrete base and fasten the wood material with dowels. The second, upper layer is attached to the first layer by means of self-tapping screws. Back to contents</a>

Characteristics of plywood. With the help of the level, the required layer is corrected, which then is neatly leveled by the wide movements of the rule. Then comes the turn of the flooring of the sheet material. Correct laying involves the placement of plywood (OSB, gipsovoloknistyh panels) in two layers. And it is necessary to lay them out so that both layers are oriented in opposite directions. It should be noted that when laying the first, lower layer over the entire area of plywood sheets, it is necessary to tap with a rubber hammer. This action will finally and reliably set the plates on the padding. Then you can drill holes in the concrete base and fasten the wood material with dowels. The second, upper layer is attached to the first layer by means of self-tapping screws. Back to contents</a>

How to level the floor on a wooden base?

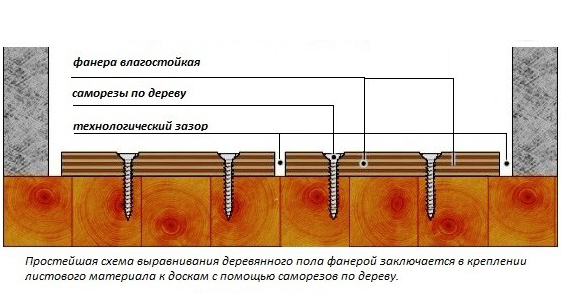

The scheme of leveling the floor with plywood without lag. Often you have to level old wooden floors. This operation is very similar to repair on concrete bases, but in the case of the woody version, there are some features that should be mentioned. Align the floor without screed on the existing plane is recommended in those cases where, in the presence of small potholes and chips, the difference between the lower and upper sections of these defects does not exceed 5 mm. If this condition is met, a little preparation should be done, which is reduced to a putty of a dilapidated wooden substrate (of course, where required) with an acrylic sealant or a mixture based on PVA glue. To level the floor on a wooden base, on which there are no serious flaws, sand as a bedding is not needed. Plywood sheets with a thickness of no more than 20 mm are simply laid out on the old, putty surface, with only one layer sufficient (for this purpose it is not recommended to use a fiberboard). Their fastening is performed with the help of lengths and diameters of self-tapping screws. When planning to level the floors without the use of cementitious screeds, it should always be remembered that the technology described above is applicable in cases where the differences in heights in the potholes do not exceed 5 mm. If these defects are greater, you will have to turn to another technology. Back to contents</a>

The scheme of leveling the floor with plywood without lag. Often you have to level old wooden floors. This operation is very similar to repair on concrete bases, but in the case of the woody version, there are some features that should be mentioned. Align the floor without screed on the existing plane is recommended in those cases where, in the presence of small potholes and chips, the difference between the lower and upper sections of these defects does not exceed 5 mm. If this condition is met, a little preparation should be done, which is reduced to a putty of a dilapidated wooden substrate (of course, where required) with an acrylic sealant or a mixture based on PVA glue. To level the floor on a wooden base, on which there are no serious flaws, sand as a bedding is not needed. Plywood sheets with a thickness of no more than 20 mm are simply laid out on the old, putty surface, with only one layer sufficient (for this purpose it is not recommended to use a fiberboard). Their fastening is performed with the help of lengths and diameters of self-tapping screws. When planning to level the floors without the use of cementitious screeds, it should always be remembered that the technology described above is applicable in cases where the differences in heights in the potholes do not exceed 5 mm. If these defects are greater, you will have to turn to another technology. Back to contents</a>

How to align the floor with lags?

Assembly diagram of the structure for leveling the floor according toregulated lags. Before opting for the specified option, the customer should make sure that a noticeable rise in the floor level is not of fundamental importance for his room. Indeed, after performing this operation, the height of the room will necessarily decrease. In order to level the floor without a screed, using a tape support from wooden beams-lags, on the walls of the room, an initial marking is made on the walls of the room for the flooring of the future horizon. Then, using the appropriate fasteners, longitudinal logs are mounted along the entire length of the room. For greater strength of the future base, additional transverse joists can be provided. In this case, the upper edges of the lags should be located in the plane marked on the walls. Here it must be borne in mind that the distance between the lags is in direct proportion to the thickness of the sheet material used. For example, if plywood with a thickness of 15 mm is taken for covering, the distance between the bars should be no more than 35 cm. If a thicker material is chosen (it will “play” less under loads), the logs can be placed at a distance of 50-55 cm from each other. Then proceed to the final stage. By this time, plywood sheets should already be cut to the size of the available spans between the beams. Their edges must necessarily lie approximately in the middle of the lag and not "hang" over the void. The sheets are attached to the wooden frame with self-tapping screws, which should be somewhat sunk into the plywood. Back to the table of contents</a>

Assembly diagram of the structure for leveling the floor according toregulated lags. Before opting for the specified option, the customer should make sure that a noticeable rise in the floor level is not of fundamental importance for his room. Indeed, after performing this operation, the height of the room will necessarily decrease. In order to level the floor without a screed, using a tape support from wooden beams-lags, on the walls of the room, an initial marking is made on the walls of the room for the flooring of the future horizon. Then, using the appropriate fasteners, longitudinal logs are mounted along the entire length of the room. For greater strength of the future base, additional transverse joists can be provided. In this case, the upper edges of the lags should be located in the plane marked on the walls. Here it must be borne in mind that the distance between the lags is in direct proportion to the thickness of the sheet material used. For example, if plywood with a thickness of 15 mm is taken for covering, the distance between the bars should be no more than 35 cm. If a thicker material is chosen (it will “play” less under loads), the logs can be placed at a distance of 50-55 cm from each other. Then proceed to the final stage. By this time, plywood sheets should already be cut to the size of the available spans between the beams. Their edges must necessarily lie approximately in the middle of the lag and not "hang" over the void. The sheets are attached to the wooden frame with self-tapping screws, which should be somewhat sunk into the plywood. Back to the table of contents</a>

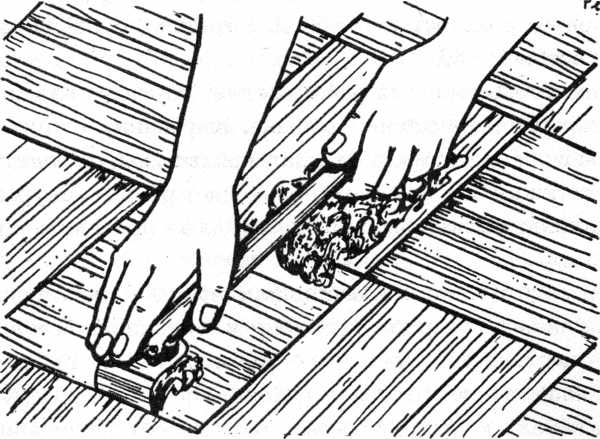

Machining of uneven floor by cycling

Cycle the floor of the cicle with an elongated handle. Align the floor in yet another way, which does not need a coupler. It is usually used in cases where the floors do not have large differences in the levels of defective potholes. The execution of the cycle work begins with the mandatory "drowning" of all the fasteners found in the floor, without exception. If you try to level the floor without this "trifle", you can eventually disable an expensive cage machine. It is equally important at this stage to determine and visually identify places that will have to be processed especially carefully. Also, all the cracks are filled up, the rotten boards are replaced with new ones. After that, you can turn on the equipment. The machine with a coarse abrasive is carried across the entire floor area, moving it diagonally and with each wire running a few times over the stripped strip. Then, having cleared the floor of the shavings and dust, put a medium-grained skin on the pulleys and make a second pass. But this time the looping is performed already parallel to the laid floorboards and again overlapped. At the final stage, to clean the floor, use a fine grain abrasive. In this case, hard-to-reach places are plowed separately by a disk grinder. Thus, it is possible to level the floor without screed, without compromising on size and quality. But for this you should always follow the simple technological rules and advice of experienced masters. </ ul>

Cycle the floor of the cicle with an elongated handle. Align the floor in yet another way, which does not need a coupler. It is usually used in cases where the floors do not have large differences in the levels of defective potholes. The execution of the cycle work begins with the mandatory "drowning" of all the fasteners found in the floor, without exception. If you try to level the floor without this "trifle", you can eventually disable an expensive cage machine. It is equally important at this stage to determine and visually identify places that will have to be processed especially carefully. Also, all the cracks are filled up, the rotten boards are replaced with new ones. After that, you can turn on the equipment. The machine with a coarse abrasive is carried across the entire floor area, moving it diagonally and with each wire running a few times over the stripped strip. Then, having cleared the floor of the shavings and dust, put a medium-grained skin on the pulleys and make a second pass. But this time the looping is performed already parallel to the laid floorboards and again overlapped. At the final stage, to clean the floor, use a fine grain abrasive. In this case, hard-to-reach places are plowed separately by a disk grinder. Thus, it is possible to level the floor without screed, without compromising on size and quality. But for this you should always follow the simple technological rules and advice of experienced masters. </ ul>