Before you do this, you should know what material it isfor this purpose use. The most common today is polystyrene foam, which is a gas-filled material made from polystyrene and styrene copolymers. Natural gas is used to produce regular polystyrene foam, while carbon dioxide is used in fire-resistant material. This material is chosen not only because it has excellent thermal insulation qualities, but also because it has a very low cost. In addition, it is easy to work with due to its low weight and the lack of need for special equipment. It has become very popular to insulate the floorpolystyrene foam, since this material is lightweight and has good thermal insulation qualities. It is necessary to choose a material that does not have peeling granules, damage or fragments, the surface should be white and uniform. Floor insulation is an integral process in the thermal insulation of a building.

It has become very popular to insulate the floorpolystyrene foam, since this material is lightweight and has good thermal insulation qualities. It is necessary to choose a material that does not have peeling granules, damage or fragments, the surface should be white and uniform. Floor insulation is an integral process in the thermal insulation of a building.

Warming of concrete floor

Insulation of concrete base with polystyrene foam.If you use expanded polystyrene granules, laying it in the screed, this will significantly reduce heat loss. The process of carrying out the work involves preparing a solution with the addition of granules, which makes the screed layer heat-insulating. Dry cement should be added to a small amount of water, mixing the composition with a drill that has a mixer attachment. The mixture should eventually acquire the consistency of sour cream. Without stopping stirring, it is necessary to add expanded polystyrene granules to the solution. In this case, you can use a ratio of concrete to granules as 1:3 or 1:6. Increasing the amount of filler, you guarantee higher thermal insulation characteristics. However, it should be taken into account that with an increase in the number of granules, the screed will be less durable. In addition to the insulating properties, the screed layer with granular filler will have soundproofing qualities. To prepare expanded polystyrene concrete, you need to prepare 2 bags of granules of the material, 100 liters of water, and 200 kg of cement. A solution prepared in such proportions will produce a mixture with a density equal to 200 kg/m3. The density can be increased to 300 kg/m3 using 120 l of water and 400 kg of cement. The density of expanded polystyrene concrete can be increased to 400 kg/m3 using 140 l of water and 400 kg of cement.

Insulation of concrete base with polystyrene foam.If you use expanded polystyrene granules, laying it in the screed, this will significantly reduce heat loss. The process of carrying out the work involves preparing a solution with the addition of granules, which makes the screed layer heat-insulating. Dry cement should be added to a small amount of water, mixing the composition with a drill that has a mixer attachment. The mixture should eventually acquire the consistency of sour cream. Without stopping stirring, it is necessary to add expanded polystyrene granules to the solution. In this case, you can use a ratio of concrete to granules as 1:3 or 1:6. Increasing the amount of filler, you guarantee higher thermal insulation characteristics. However, it should be taken into account that with an increase in the number of granules, the screed will be less durable. In addition to the insulating properties, the screed layer with granular filler will have soundproofing qualities. To prepare expanded polystyrene concrete, you need to prepare 2 bags of granules of the material, 100 liters of water, and 200 kg of cement. A solution prepared in such proportions will produce a mixture with a density equal to 200 kg/m3. The density can be increased to 300 kg/m3 using 120 l of water and 400 kg of cement. The density of expanded polystyrene concrete can be increased to 400 kg/m3 using 140 l of water and 400 kg of cement. List of tools for floor insulation.In all the cases described, foam plastic granules should be used in a volume of 0.8 m3. This is equivalent to two bags of 0.4 m3 each. To carry out insulation work, it is necessary to prepare:

List of tools for floor insulation.In all the cases described, foam plastic granules should be used in a volume of 0.8 m3. This is equivalent to two bags of 0.4 m3 each. To carry out insulation work, it is necessary to prepare:

- a drill with a nozzle;

- water;

- cement;

- polystyrene pellets;

- capacity;

- shovel.

Return to Contents</a>

Warming of floors with expanded polystyrene sheets

Thermal insulation of the floor with logs usingpolystyrene foam. Polystyrene foam can be used to insulate the floor and the ground, which must first be compacted. Then a layer of crushed stone is poured, and on top - a layer of sand, after which a film is laid on the cushion. At the next stage, it is necessary to lay the insulation sheets, filling the resulting joints with polyurethane foam. The next layer is film. In order to protect the sheets from mechanical impact during operation, a mounting mesh should be laid on top. Next, it is necessary to prepare a solution for pouring the screed and arrange the floor, the thickness of which should be equal to the limit of 40-60 mm. After the rough coating has gained its strength, you can proceed to laying the finishing floor. Return to the table of contents</a>

Thermal insulation of the floor with logs usingpolystyrene foam. Polystyrene foam can be used to insulate the floor and the ground, which must first be compacted. Then a layer of crushed stone is poured, and on top - a layer of sand, after which a film is laid on the cushion. At the next stage, it is necessary to lay the insulation sheets, filling the resulting joints with polyurethane foam. The next layer is film. In order to protect the sheets from mechanical impact during operation, a mounting mesh should be laid on top. Next, it is necessary to prepare a solution for pouring the screed and arrange the floor, the thickness of which should be equal to the limit of 40-60 mm. After the rough coating has gained its strength, you can proceed to laying the finishing floor. Return to the table of contents</a>

Thermal insulation of the floor with lags

Quite often, the floor is insulated with polystyrene foam,which is supplied with a system of logs in advance. This simplifies the process of laying the insulation. Initially, the wooden components of the floor should be treated with antifungal compounds and moisture-protective agents. After that, boards or chipboard should be fixed to the bottom of the beams with screws, which will allow you to lay sheets of material cut to the size of the opening on the formed surface. From above, the resulting layers must be covered with a film, on which the final floor covering is laid. As a filler for the space between the logs and foam plastic along the perimeter along the walls, it is preferable to use URSA insulation based on fiberglass, this is due to the fact that this solution will cost less compared to polyurethane foam. Return to contents</a>

Features of the work with insulation with expanded polystyrene

When using polystyrene foam asRoll waterproofing is often used as insulation, and it should be laid with an overlap of 10 cm in width. The strips should be secured with tape. Table of properties of polystyrene foam.The application of a screed over expanded polystyrene thermal insulation of the first floor is also carried out in the case when a floor based on logs on the ground is arranged under the floor covering. In this situation, after dismantling the flooring from the boards, a cushion should be created from a layer of expanded clay, while the logs can be removed or left. In the first case, the backfill is made on the soil, a waterproofing layer is laid on top, laid with an overlap, the width of which is equal to 10 cm, the joints must be glued with foam-foil tape. If there are logs, it is necessary to cover only the gaps between them. If large gaps remain, then they can be eliminated by using wedges made of insulation. If the floor in the space of a cold attic or loft is insulated with expanded polystyrene, then the technology will be slightly different from that used for thermal insulation of a concrete floor. The difference will be that under the flooring of the heat insulator it is necessary to lay a layer not of hydro- but of vapor barrier material, this requirement is explained by the fact that the ceiling of the upper floor, which acts as the floor of the attic, must breathe. The heat insulator can be laid on this vapor barrier, on top of which it is necessary to lay a layer of the same material, then it is permissible to proceed to the arrangement of a concrete screed or installation of lathing, on which the subfloor will be laid. The final layer will be the finishing coating. It is possible to insulate the floor with expanded polystyrene in the attic, using extruded material, the laying of which is carried out in several layers with mismatched joints of the slabs between themselves. If it is supposed to use a wood covering in the form of fiberboard or parquet as the final flooring, then it is necessary to arrange the lathing on top of the heat insulation and foam-foil sheet, placing it according to the level. If the finishing material for the insulated floor is to be tiles, then the surface of the polystyrene foam must be covered with a vapor barrier and reinforced screed, after which you can begin laying the tiles on the glue.

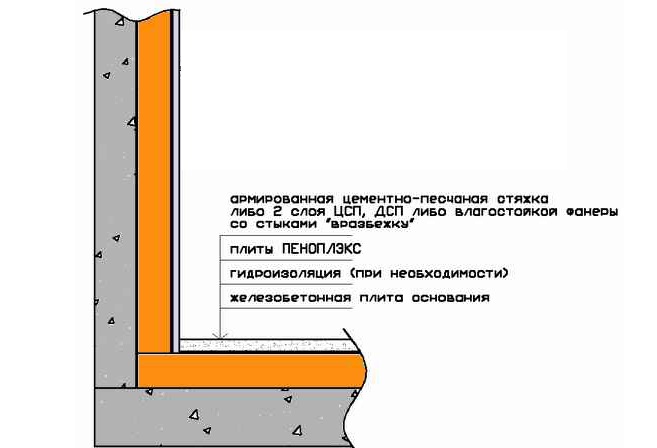

Table of properties of polystyrene foam.The application of a screed over expanded polystyrene thermal insulation of the first floor is also carried out in the case when a floor based on logs on the ground is arranged under the floor covering. In this situation, after dismantling the flooring from the boards, a cushion should be created from a layer of expanded clay, while the logs can be removed or left. In the first case, the backfill is made on the soil, a waterproofing layer is laid on top, laid with an overlap, the width of which is equal to 10 cm, the joints must be glued with foam-foil tape. If there are logs, it is necessary to cover only the gaps between them. If large gaps remain, then they can be eliminated by using wedges made of insulation. If the floor in the space of a cold attic or loft is insulated with expanded polystyrene, then the technology will be slightly different from that used for thermal insulation of a concrete floor. The difference will be that under the flooring of the heat insulator it is necessary to lay a layer not of hydro- but of vapor barrier material, this requirement is explained by the fact that the ceiling of the upper floor, which acts as the floor of the attic, must breathe. The heat insulator can be laid on this vapor barrier, on top of which it is necessary to lay a layer of the same material, then it is permissible to proceed to the arrangement of a concrete screed or installation of lathing, on which the subfloor will be laid. The final layer will be the finishing coating. It is possible to insulate the floor with expanded polystyrene in the attic, using extruded material, the laying of which is carried out in several layers with mismatched joints of the slabs between themselves. If it is supposed to use a wood covering in the form of fiberboard or parquet as the final flooring, then it is necessary to arrange the lathing on top of the heat insulation and foam-foil sheet, placing it according to the level. If the finishing material for the insulated floor is to be tiles, then the surface of the polystyrene foam must be covered with a vapor barrier and reinforced screed, after which you can begin laying the tiles on the glue. Scheme of floor insulation with polystyrene foam.Despite the fact that the material is easy to cut, it is preferable to cut it after careful measurements and with a hot nichrome wire. When laying the material, do not expose it to organic mastics and resins. When installing the sheets, it is necessary to leave gaps of 1 cm near the walls along the perimeter of the room, which will act as technological and ventilation grooves. Expanded polystyrene can be laid under the underfloor heating system. In this case, before laying the vapor barrier layer on top of the heat insulator along the perimeter of the walls, it is necessary to lay a damper tape, this is necessary to compensate for changes in the linear dimensions of the screed during the operation of the heating system. Expanded polystyrene has insignificant thermal conductivity, which is why the material is so popular among private developers and professional builders. Lightweight sheets are easy to transport, even without ordering heavy equipment, and working with the heat insulator is quite easy. It is only important to choose which insulation technology will be used before starting work, which will allow dividing the process into several stages.

Scheme of floor insulation with polystyrene foam.Despite the fact that the material is easy to cut, it is preferable to cut it after careful measurements and with a hot nichrome wire. When laying the material, do not expose it to organic mastics and resins. When installing the sheets, it is necessary to leave gaps of 1 cm near the walls along the perimeter of the room, which will act as technological and ventilation grooves. Expanded polystyrene can be laid under the underfloor heating system. In this case, before laying the vapor barrier layer on top of the heat insulator along the perimeter of the walls, it is necessary to lay a damper tape, this is necessary to compensate for changes in the linear dimensions of the screed during the operation of the heating system. Expanded polystyrene has insignificant thermal conductivity, which is why the material is so popular among private developers and professional builders. Lightweight sheets are easy to transport, even without ordering heavy equipment, and working with the heat insulator is quite easy. It is only important to choose which insulation technology will be used before starting work, which will allow dividing the process into several stages.