To make the house cozy and comfortable forliving, it is necessary first of all to take care of its thermal insulation. In this case, special attention should be paid to the first floor, as it is located closest to the ground base. If the house has poor thermal insulation, then all the heat will go into the ground. Scheme of the insulated floor of the first floor.To compensate for heat loss, it is necessary to increase heating, which leads to an increase in material costs for servicing the house. Insulating the floor on the first floor will help solve this problem.

Scheme of the insulated floor of the first floor.To compensate for heat loss, it is necessary to increase heating, which leads to an increase in material costs for servicing the house. Insulating the floor on the first floor will help solve this problem.

Choosing a method of floor insulation on the first floor

The choice of thermal insulation method depends primarilyqueue from the material from which the floor on the first floor is made. If the floor is wooden, then it makes sense to make insulation with mineral wool or foam. A concrete floor can be insulated with polystyrene foam, gypsum fiber board or fiberboard. If you want not only, but also to simultaneously improve the heating system, then it makes sense to arrange a warm floor system. Insulation of the floor on the first floor can beexternal and internal. When installing external thermal insulation, the floor is insulated not only from the inside of the house, but also from the basement. Often, it is impossible to carry out internal thermal insulation due to communications located in the basement. It is not recommended to attach foam plastic to the bottom of the slab, as this does not comply with fire safety standards. It is impossible to use mineral insulation, as it will quickly deteriorate due to exposure to moisture. Very often, the only way is to close all ventilation openings for the winter. It should be remembered that if you live in an apartment building, then all insulation actions must be legally agreed upon. Return to contents</a>

Insulation of the floor on the first floor can beexternal and internal. When installing external thermal insulation, the floor is insulated not only from the inside of the house, but also from the basement. Often, it is impossible to carry out internal thermal insulation due to communications located in the basement. It is not recommended to attach foam plastic to the bottom of the slab, as this does not comply with fire safety standards. It is impossible to use mineral insulation, as it will quickly deteriorate due to exposure to moisture. Very often, the only way is to close all ventilation openings for the winter. It should be remembered that if you live in an apartment building, then all insulation actions must be legally agreed upon. Return to contents</a>

Warming of the floor on the first floor with mineral wool

Insulating the floor with mineral wool is bestSuitable for wooden floors in an apartment. At the same time, this option is perfect if you are not satisfied with the quality of the floor covering. The technology of insulating the floor with mineral wool is quite simple. First, you should remove the existing boards (having numbered them in advance). After that, check the condition of the vapor barrier (if any) and the tightness of the base. All cracks found are sealed with polyurethane foam. If the vapor barrier is in poor condition, it should be replaced. Next, mineral wool is placed between the joists, and floorboards are laid on top. When laying mineral wool slabs, you need to carefully monitor how tightly they fit the walls and joists. The tighter they are laid, the better the insulation will be. Scheme of floor insulation with mineral wool.The insulation of the floor on the first floor can be done with the help of polystyrene foam. Polystyrene foam sheets can also be laid under a wooden floor. The insulation is done in the same way as mineral wool. The difference is that the polystyrene foam sheets should be laid with small gaps. After all the sheets are laid, all the cracks need to be filled with polyurethane foam. This way the insulation will form one continuous layer. Return to the table of contents</a>

Scheme of floor insulation with mineral wool.The insulation of the floor on the first floor can be done with the help of polystyrene foam. Polystyrene foam sheets can also be laid under a wooden floor. The insulation is done in the same way as mineral wool. The difference is that the polystyrene foam sheets should be laid with small gaps. After all the sheets are laid, all the cracks need to be filled with polyurethane foam. This way the insulation will form one continuous layer. Return to the table of contents</a>

How to insulate the floor with a fiberboard or drywall

The first thing to do is remove the floor covering andif necessary, level the concrete base. If there are any cracks, fill all the recesses. When the concrete screed is completely dry, lay a layer of vapor barrier. In this case, you need to make a small bend on the walls. Then lay the first layer of gypsum board sheets 12 mm thick and treat it with adhesive mastic. Lay the second layer on top so that the joints do not coincide. When the adhesive mastic is completely dry, prime the surface and fill it. Then lay the selected floor covering. To compensate for the expansion of the material after exposure to moisture or temperature changes, place an edge tape between the ends of the sheets and the wall. When insulating the floor with fiberboard, you must first remove the baseboards. Then nail the fiberboard to the floor, and glue the floor covering (carpet or linoleum) on top. The glue dries completely only after 24 hours. Return to contents</a>

How to insulate the floor on the ground floor with a pen-plex

Scheme of floor insulation with polystyrene foam.(or penoplex) is suitable for laying various coverings (linoleum, parquet, laminate, wooden boards, ceramic tiles). To do this, you should clean the floor covering to the concrete screed (you can leave only ceramic tiles) and lay a layer of vapor barrier on it. Then lay the sheets of penoplex. A layer of polyethylene film should be laid on top of the sheets. Then you need to make a reinforcing screed from cement mortar. After it has completely dried, you can start laying the floor covering. Return to the table of contents</a>

Scheme of floor insulation with polystyrene foam.(or penoplex) is suitable for laying various coverings (linoleum, parquet, laminate, wooden boards, ceramic tiles). To do this, you should clean the floor covering to the concrete screed (you can leave only ceramic tiles) and lay a layer of vapor barrier on it. Then lay the sheets of penoplex. A layer of polyethylene film should be laid on top of the sheets. Then you need to make a reinforcing screed from cement mortar. After it has completely dried, you can start laying the floor covering. Return to the table of contents</a>

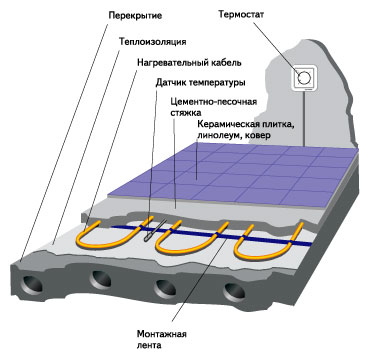

Arrangement of a warm floor

There are several types of heated floors:water, electric, film and infrared. The most economical option is a water heating system, as it does not require large installation and maintenance costs. Electric underfloor heating is also easy to install, but it has two significant drawbacks:

- electromagnetic radiation adversely affects the health of people;

- Electric heated floor significantly increases electricity consumption.

There are several ways to install a water-heated floor:

Warm floor scheme.Most often, the first method of laying is used to insulate the floor on the first floor. To do this, first divide the area into sectors (to compensate for the temperature expansion of the screed) and prepare the necessary tools and materials:

Warm floor scheme.Most often, the first method of laying is used to insulate the floor on the first floor. To do this, first divide the area into sectors (to compensate for the temperature expansion of the screed) and prepare the necessary tools and materials:

Return to Contents</a>Technology of laying water heated floors On the floorheat-insulating material (penoplex or polystyrene foam) is laid, which will reduce heat loss. A damper tape is laid around the perimeter of the room (to compensate for thermal expansion of the screed). A reinforcing mesh is laid on the thermal insulation, to which the pipes will be attached. The pipes are most often laid in a spiral. The pipes themselves are attached to the mesh using special clamps with a step of 1 m. Do not attach the pipes to the reinforcement too tightly, since under the influence of temperature they can expand and deform if the screed is too dense. The step for laying pipes is 10-35 cm. The distance from the wall to the nearest pipe should be at least 7 cm. One end of the pipe should be fixed to the supply manifold. According to a pre-drawn diagram, the pipes are attached along the contours. The second end of the pipe is connected to the return manifold. When the pipe passes through the seam between the contours, a special corrugated pipe is put on it. Before performing the screed, it is necessary to check the functionality of the structure and determine whether there is a leak. To do this, water is poured into the pipes under high pressure. Testing should be carried out only in the presence of an experienced craftsman. After successful testing, the floor screed is performed using special mixtures for warm floors. Water must circulate in the pipes during the work. When the screed dries, you can lay the floor covering. This method is more labor-intensive and expensive than the previous ones, but the effect you get compensates for all the efforts and expenses.</ ul>