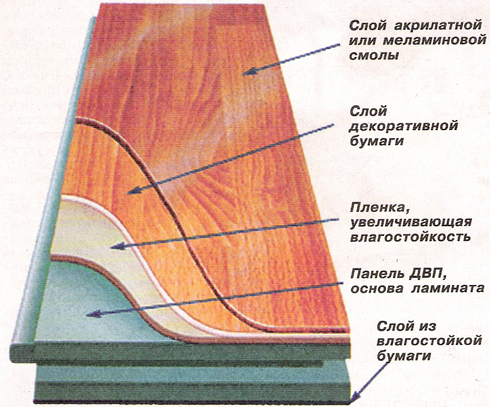

Laminate flooring is found in almost all buildings today.— both residential and commercial. Its cost varies significantly, which means that buying laminate flooring is available to all categories of the population. In new houses with a smooth floor screed it is quite simple, but there are also houses with wooden floors. on a plank floor - the task is more difficult than on smooth concrete. Laminate board diagram.

Laminate board diagram.

Preparation of the working surface

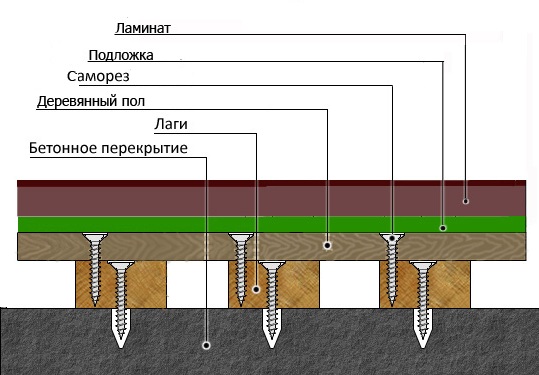

You need to start by preparing the floor:it is necessary to vacate the premises and carefully inspect the condition of the floor covering. If there are loose parts, they need to be secured; self-tapping screws will do. In no case should the presence of fungus, dampness and rottenness of the wooden floor be allowed. If something like this is present, then it is imperative to get rid of it. Laying laminate on a wooden base. If the old floor is installed on joists, it is necessary to check their integrity and, if necessary, strengthen them. What methods can be used to detect the location of the joists?

Laying laminate on a wooden base. If the old floor is installed on joists, it is necessary to check their integrity and, if necessary, strengthen them. What methods can be used to detect the location of the joists?

It is recommended to fill the existing voids withhelp of insulation. It would not be superfluous to paint the old plank floor, this will help protect the coating from moisture. All cracks that are found during the inspection must be filled. Walk around the entire room, preferably not just one, but several people at once, and check if the boards creak. If you find places where the boards are worn out or creaking, then you need to get rid of these defects immediately. Dried out floorboards will have to be re-beaten, in some cases it is more advisable to replace the boards with new ones. If there are visible deformations, you can cycle the floor surface, then sand it. This will help get rid of minor irregularities in the floor covering. Return to contents</a>

Alignment: Tips for the process

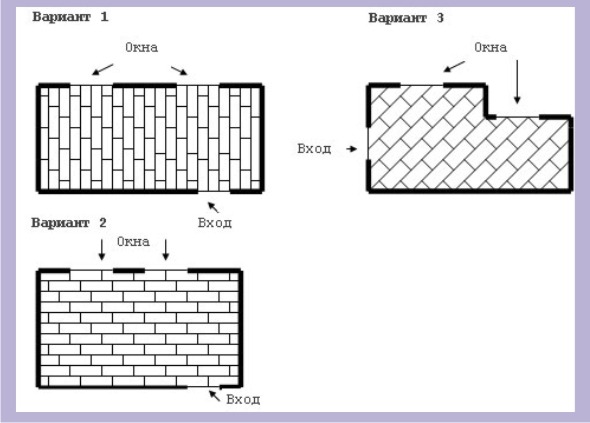

Options for laying laminate flooring in a room.After the floor has been checked, you need to find out how level it is. Laminate flooring is laid on a level surface. You need to stock up on a plumb line and use it to identify differences in height. If the differences are slightly more than 2 mm, they can be easily eliminated with a grinder. If the floor has more significant differences, you need to resort to a more labor-intensive process. Leveling can be done in several ways: make a special floor screed designed specifically for wooden structures, or lay sheets of plywood or chipboard and secure them with screws. The option with a screed is preferable and more reliable, but in this case you need to choose the right mixture - give preference to those companies that have already proven themselves in this matter. To make the floor durable and reliable, you can eliminate defects with a mixture made of varnish, sawdust and putty. This mixture will help get rid of insects living in wood and their nests. Before you sand and polish the surface, you should make sure that this is a necessary process and that it will not cause any harm. If you remove a thick layer of coating, it will weaken the structure, which is highly undesirable. Do not lay laminate on a creaking floor under any circumstances. Creaking indicates that the floor is mobile, which means that the laminate will sag with it, which will primarily damage the joints and, as a result, shorten the service life. This is especially important if you plan to put furniture in the room. Before you begin the process of laying the laminate, you need to cover the floor with a substrate.

Options for laying laminate flooring in a room.After the floor has been checked, you need to find out how level it is. Laminate flooring is laid on a level surface. You need to stock up on a plumb line and use it to identify differences in height. If the differences are slightly more than 2 mm, they can be easily eliminated with a grinder. If the floor has more significant differences, you need to resort to a more labor-intensive process. Leveling can be done in several ways: make a special floor screed designed specifically for wooden structures, or lay sheets of plywood or chipboard and secure them with screws. The option with a screed is preferable and more reliable, but in this case you need to choose the right mixture - give preference to those companies that have already proven themselves in this matter. To make the floor durable and reliable, you can eliminate defects with a mixture made of varnish, sawdust and putty. This mixture will help get rid of insects living in wood and their nests. Before you sand and polish the surface, you should make sure that this is a necessary process and that it will not cause any harm. If you remove a thick layer of coating, it will weaken the structure, which is highly undesirable. Do not lay laminate on a creaking floor under any circumstances. Creaking indicates that the floor is mobile, which means that the laminate will sag with it, which will primarily damage the joints and, as a result, shorten the service life. This is especially important if you plan to put furniture in the room. Before you begin the process of laying the laminate, you need to cover the floor with a substrate. The process of laying laminate.Usually, either rolled cork or foamed polyethylene plays this role. You can buy it in construction stores. What does the use of a substrate give: increased insulation of both heat and sound, this is especially valuable if you live in a multi-story building. The substrate also helps distribute the mechanical load over the entire area of the room. The substrate is attached quite easily - either linearly or partially using tape or construction adhesive tape. An important rule: laying laminate on a plank floor is done perpendicular to the boards. Return to contents</a>

The process of laying laminate.Usually, either rolled cork or foamed polyethylene plays this role. You can buy it in construction stores. What does the use of a substrate give: increased insulation of both heat and sound, this is especially valuable if you live in a multi-story building. The substrate also helps distribute the mechanical load over the entire area of the room. The substrate is attached quite easily - either linearly or partially using tape or construction adhesive tape. An important rule: laying laminate on a plank floor is done perpendicular to the boards. Return to contents</a>

Laminate flooring: practical recommendations

Before you begin the process of laying laminate, you need to buy everything you will need in the process: Scheme of correct laminate installation.

Scheme of correct laminate installation.

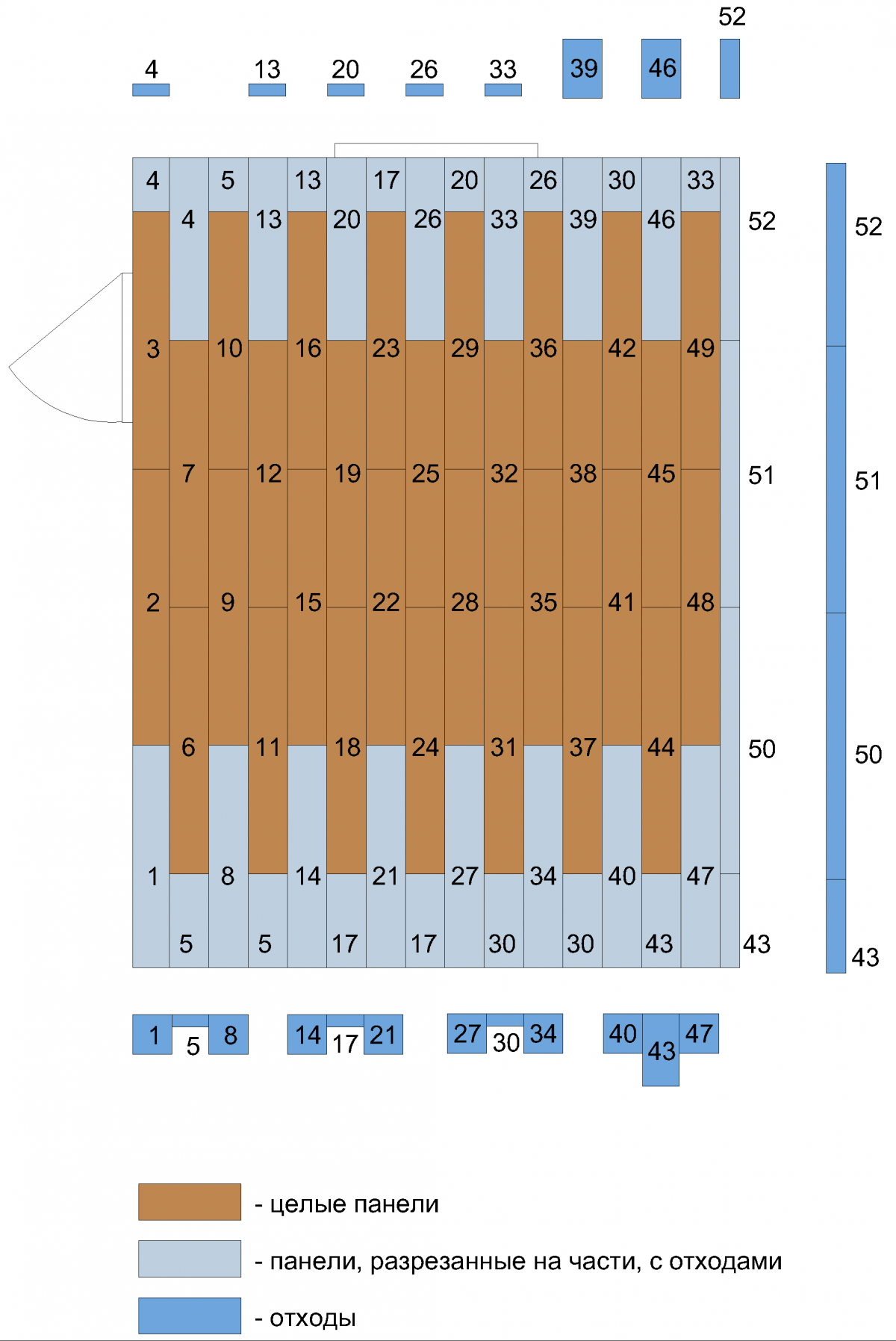

After the work surface has passedthorough preparation, you can start installing the flooring. You need to buy the main material (i.e. laminate), bring it home and leave it for 2 days in a room with humidity up to 75%. In the store (or find something suitable at home), you need to buy wedges that will be between the wall and the 1st row of laminate. The wedges must be of the same thickness, they must be removed after the installation process is complete. What are they for: during installation, the 1st row of the flooring should not rest against the wall. The laminate is laid end to end, so in order to hide the joints, it is recommended to lay it against the light falling from the window. How to install: the panel that will be laid in the 1st row must first be laid along the room along its entire length and measure out the required footage. Saw off the excess, do the same with all subsequent rows. It happens that during the process of laying the laminate you have to deal with protruding parts (for example, a pipe). In this case, you will have to cut out the necessary hole, making the correct measurements. In this way, the laying takes place over the entire area of the room. After the last row of laminate is laid, you can remove the wedges. The next step is to install thresholds and baseboards. The amount of laminate and waste during installation. What other nuances of laminate installation should you know before starting work:

The amount of laminate and waste during installation. What other nuances of laminate installation should you know before starting work:

Return to Contents</a>

How to connect the laminate properly?

How is laminate flooring laid in a room?described above, but what to do when you need to lay the flooring between rooms? The process of installing laminate flooring between rooms is similar, but the connection requires special attention. The gaps in the flooring between rooms need to be covered with special profiles, they can be found in hardware stores. As a rule, interior doors are installed only after the laminate has already been laid. But it also happens that the door is already installed, in which case you will have to saw the frame a little. This work is very painstaking and requires high concentration and accuracy. So, joining the laminated flooring is necessary when:

- there is a transition between the rooms;

- the room is very large;

- Within one room there are several types of coverings;

- there is a difference in the level of the floor, which can not be eliminated.

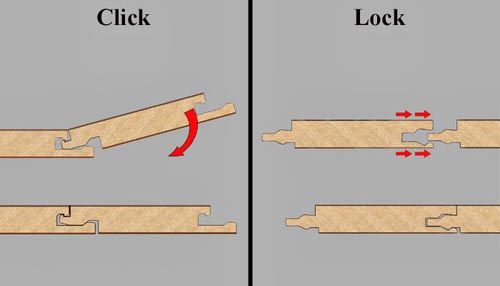

Types of laminate locks - Click and Lock.Laminate flooring has a locking connection, which is strong enough and therefore does not allow the panels to move freely in conditions of temperature and humidity changes. It is for this reason that wedges are placed between the wall and the flooring so that the laminate has room to expand later. It is also recommended to install such gaps in places of doorways, where they will not be noticeable. Today it is much easier - you do not need to think about how to design the connection between the floors. As a rule, manufacturers of laminate flooring have all the necessary components. This includes: underlay, baseboards and connecting strips, also known as thresholds or connecting profiles. Thresholds differ from each other in shape, color and material of manufacture. Return to contents</a>

Types of laminate locks - Click and Lock.Laminate flooring has a locking connection, which is strong enough and therefore does not allow the panels to move freely in conditions of temperature and humidity changes. It is for this reason that wedges are placed between the wall and the flooring so that the laminate has room to expand later. It is also recommended to install such gaps in places of doorways, where they will not be noticeable. Today it is much easier - you do not need to think about how to design the connection between the floors. As a rule, manufacturers of laminate flooring have all the necessary components. This includes: underlay, baseboards and connecting strips, also known as thresholds or connecting profiles. Thresholds differ from each other in shape, color and material of manufacture. Return to contents</a>

Some features

It is highly desirable to do so immediately upon purchasing the coating.ask the seller about the components to choose what you need in a particular case. Agree that you won't want to waste time on this later. The so-called thresholds are divided into:

- Straight, which is used for joints of laminate with a different coating or for laminate of different types, having different joints;

- Transitional are used in those cases when it is necessary to connect the coverings at different heights;

- angular ones are irreplaceable when it is required to make a joint on perpendicular surfaces (for example, on stairs or a podium);

- The final one is used when there is a need to close the open edge of the laminated cover, that is, the frame.

There is also a division of profiles by materials.They can be made of metal, laminated, plastic and rubber. The choice will depend on the purpose. Laminated profile is perfect in cases where you need an invisible connection of the covering between rooms. Such a profile is covered with a film and can be selected to match the color and even the pattern of a specific covering. It is most often used in doorways. Metal ones are also covered with a film, but due to their strength they are more often used in places with high traffic (for example, corridors and hallways). Plastic ones are inexpensive and have a huge variety of colors. In addition, they are quite flexible and soft, so they are used in the design of uneven joints, the service life of such thresholds is short. Rubber profiles are more often used on steps, they reduce the risk of slipping.