It's no secret that there are no sexes better than those thatmade of wood. However, over time, the parquet board can be deformed, which is why the coating loses its aesthetic and practical qualities. Solve the problem of worn wood floor with a laminate.  Structure of the laminate board. By itself, laying this kind of flooring - the task is not for beginners. Including the restoration of the floor with the help of laminate flooring on chipboard, plywood or fiberboard. Therefore, it makes sense to consider how to properly lay a laminate board on a wooden floor.

Structure of the laminate board. By itself, laying this kind of flooring - the task is not for beginners. Including the restoration of the floor with the help of laminate flooring on chipboard, plywood or fiberboard. Therefore, it makes sense to consider how to properly lay a laminate board on a wooden floor.

Advantages of laying a laminate on logs

Restoring the floor covering by laying a laminate on a wooden floor is a popular solution. Its advantages are:

- the speed of the process;

- Possibility to lay heat and soundproof materials under the lags;

- low cost of professional installation;

- the ability to conduct communications under the floor without the need for additional installation work.

Back to contents</a>

Preparation and implementation of works

To install the laminate on chipboard, plywood or fiberboard gave the expected result, it is necessary to prepare the surface and the material itself. List of tools and materials that will be needed for work:  Tools for laying laminate.

Tools for laying laminate.

- laminated board;

- Particleboard, fiberboard or plywood;

- beams for installing floor covering (lag);

- substrate for laminate;

- insulating materials;

- glue (liquid nails);

- self-tapping screws;

- level;

- sealant;

- antiseptic and protective agents for wood;

- electric drill;

- Screwdriver;

- grinding machine;

- electric jigsaw;

- roulette, ruler and pencil.

Having bought a laminate and brought it home,it is necessary to let the product get used to the climatic conditions of the room. And this rule should work not only in the case of a difference between outdoor and indoor temperatures in order to avoid deformation of the floor after laying. The board must take the temperature and humidity parameters of the room, the coating of which is planned to be replaced. In accordance with the generally accepted recommendation, the adaptation process takes about 48 hours. Laminate unpack is not necessary. At the end of the period of habituation, you should touch the board you purchased with the purpose of identifying the marriage, as well as carefully study the label and the instructions on it. If you plan to lay the laminate floor heating system, make sure that the product you purchased is suitable for this purpose by finding the appropriate markings on the label.  Lag fastening scheme.It is necessary to accurately calculate and carefully saw the laminate as required by the planned floor design. The stereotype that in hard-to-reach places you can cut the board at random and then paint over with acrylic is just a myth. Please note that any work done in parallel with wall painting, wallpapering or tile installation should be excluded. Otherwise, the floor can quickly "crawl". When the preparation of the material is finished, you can proceed to the preparation of the surface. The correct base for a laminated board is a perfectly flat work surface. Without it, laying the laminate will simply be impossible, otherwise the decorative flooring will quickly lose its appearance, begin to sink and break. The best option for creating the perfect floor is considered to be the installation of the laminate on the logs. To produce it, you will need plywood, fiberboard or chipboard, which are superimposed on the logs, that is, special beams designed for installing floor slabs. In the matter of choosing between plywood sheet, fiberboard and particleboard, you need to build on financial capabilities and the expected result. Chipboard is a cheap material, since it is glued from wood fibers under a press. It perfectly keeps heat and self-tapping screws, has an excellent astringent effect due to the presence of formaldehyde resins. Its disadvantage lies in resins, which do not have the best effect on human health. Fibreboard is more expensive because it is made with a wet wood chip press. It is denser and serves as an excellent insulation, but it holds the bend worse. And here the useful properties of plywood come in handy, which combines the advantages of both flooring options. Lags must be prepared in advance. This is due to the fact that when laying logs, preparation is also required. Necessary:

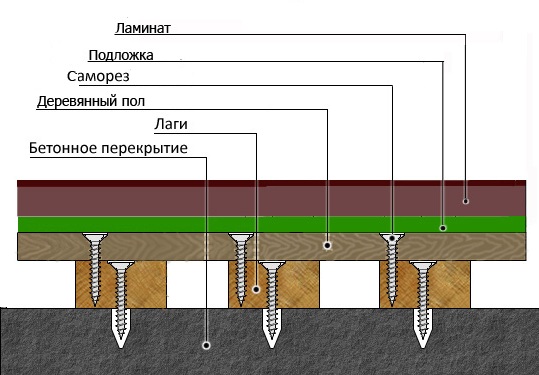

Lag fastening scheme.It is necessary to accurately calculate and carefully saw the laminate as required by the planned floor design. The stereotype that in hard-to-reach places you can cut the board at random and then paint over with acrylic is just a myth. Please note that any work done in parallel with wall painting, wallpapering or tile installation should be excluded. Otherwise, the floor can quickly "crawl". When the preparation of the material is finished, you can proceed to the preparation of the surface. The correct base for a laminated board is a perfectly flat work surface. Without it, laying the laminate will simply be impossible, otherwise the decorative flooring will quickly lose its appearance, begin to sink and break. The best option for creating the perfect floor is considered to be the installation of the laminate on the logs. To produce it, you will need plywood, fiberboard or chipboard, which are superimposed on the logs, that is, special beams designed for installing floor slabs. In the matter of choosing between plywood sheet, fiberboard and particleboard, you need to build on financial capabilities and the expected result. Chipboard is a cheap material, since it is glued from wood fibers under a press. It perfectly keeps heat and self-tapping screws, has an excellent astringent effect due to the presence of formaldehyde resins. Its disadvantage lies in resins, which do not have the best effect on human health. Fibreboard is more expensive because it is made with a wet wood chip press. It is denser and serves as an excellent insulation, but it holds the bend worse. And here the useful properties of plywood come in handy, which combines the advantages of both flooring options. Lags must be prepared in advance. This is due to the fact that when laying logs, preparation is also required. Necessary:  Laying the laminate on a wooden base.

Laying the laminate on a wooden base.

- Pave a plywood base, fiberboard or chipboard;

- cover it with steam and moisture insulating material;

- treat the beams with an antiseptic.

Lags are attached to the base with self-tapping screws. While laying them, you need to monitor the level of the floor - it should be perfect. At the end of the work, the logs must create a kind of grid-base for laying the base under the laminate. For it, chipboard or fiberboard board is suitable. Please note that, despite the softness of the material, the special laminate substrate remains one of the necessary components for installing a new floor. The second layer of overlap is fixed to the logs with the help of screws and glue. In this case, the screws are screwed in such a way that their hats do not protrude. This can be achieved by pre-drilling the board. To create a perfectly smooth surface of the substrate under the laminate, polishing of plywood, coating it with varnish and protective agents is also performed. To overlap the concrete floor with a laminate, it is necessary to lay logs and adhere to the system described above. There is an exception: there is no need to lay the first layer of plywood when working with a concrete floor. Back to contents</a>

Technology of restoration of a wooden floor with the help of a laminate

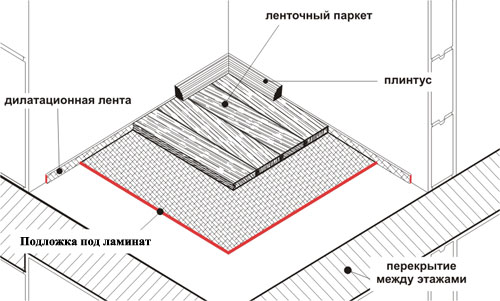

When the logs are laid and closed, thelaying a special substrate under the laminate. To give advice on how to choose it, you can, based only on how much you are willing to pay for it, what is the humidity in the room and how equal is the floor in it.  Layout of the substrate under the laminate. Foam plastic under the laminate is cheap and easy to use. They are soft enough, which means that the floor beneath them must be flawlessly even and must be provided with steam and waterproofing materials, which will protect it from the scuffing under the film. Cork substrates are equally easy to lay, but more rigid, breathable and environmentally friendly. However, they also require moisture insulation, considerable capital investment due to the high price. When the substrate is laid, the laminate is directly laid. Most modern laminated boards are equipped with a locking system of grooves and ridges, thanks to which the installation becomes a child's play: the comb of one board must be inserted into the groove of the other. It is necessary to adhere to the following important rules for laying the board:

Layout of the substrate under the laminate. Foam plastic under the laminate is cheap and easy to use. They are soft enough, which means that the floor beneath them must be flawlessly even and must be provided with steam and waterproofing materials, which will protect it from the scuffing under the film. Cork substrates are equally easy to lay, but more rigid, breathable and environmentally friendly. However, they also require moisture insulation, considerable capital investment due to the high price. When the substrate is laid, the laminate is directly laid. Most modern laminated boards are equipped with a locking system of grooves and ridges, thanks to which the installation becomes a child's play: the comb of one board must be inserted into the groove of the other. It is necessary to adhere to the following important rules for laying the board:

- laminate is laid from the door;

- the laying is made in the direction of the length of the plate from the door to the opposite wall;

- Installation must be carried out in the sequence "comb-groove".

For a more aesthetic appearance of the laminate flooring, each row is recommended to be shifted to half-boards. Back to contents</a>

Errors that are made when laying a laminate

Errors in laying the laminate and their consequences. It may seem that all the tricks of the laminate board are described above. But in order to lay the laminate really high, you need to take into account the most common mistakes:

Errors in laying the laminate and their consequences. It may seem that all the tricks of the laminate board are described above. But in order to lay the laminate really high, you need to take into account the most common mistakes:

- inaccurate, rapid pruning of the laminate;

- The absence of sealant on the joints of plates;

- the use of a hammer to fasten the planks among themselves;

- the absence of a hardened base under heavy furniture;

- neglect of insulating materials and special substrate;

- no allowance for free laying (gaps along the walls) along the perimeter of the canvas.

Laminate laying is not an easy task. If you doubt that you can create a flooring from fiberboard, chipboard or plywood, properly process the tree, lay logs, carefully mount the flooring, trim or lay the laminate yourself, better entrust this work to the master.