Laminate is a relatively new productfloor covering, but has already managed to win the recognition of consumers. In order to get a quality result, you should know how to lay laminate on a concrete floor, because only then will you be able to get a covering that will be characterized by strength, durability and excellent aesthetic characteristics. Laminate design diagram.The floor must be durable, which should be taken care of at the preparatory stage, as this will determine whether the boards will bend and creak during use.

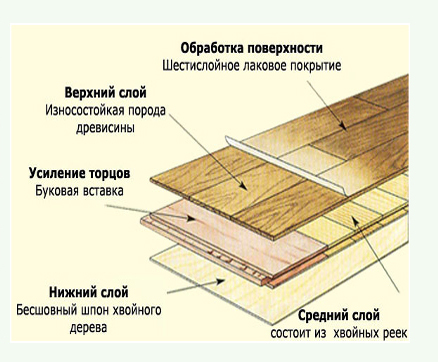

Laminate design diagram.The floor must be durable, which should be taken care of at the preparatory stage, as this will determine whether the boards will bend and creak during use.

Features of installing a laminate cover

The installation process involves three stepsstages of work, the first of which involves analyzing the suitability of the floor, the second - the selection and installation of the underlay layer, and the third stage will be accompanied by laying the board. If you neglect the first or second point, the floor covering will not be durable, and the base will be uneven. Return to the table of contents</a>Surface preparation Scheme of concrete floor screed.Preparing the surface of a concrete floor involves checking it for bumps and depressions. The former can be removed by carefully beating them off with a hammer, while chips or cracks can be repaired with concrete mortar. Particular attention should be paid to differences in height, which should not be more than 3 mm. In order to eliminate such errors, the surface can be leveled by installing a thin screed, which you can prepare yourself using water, cement and sand. You can resort to pouring a self-leveling mixture. Before starting the laying process after pouring such a mixture, you should wait 3 days. Return to the table of contents</a>Laying the underlay Before , it is necessaryprotect the floor surface with underlays, of which there should be two, each with its own purpose. The materials should have vapor and sound insulation qualities.

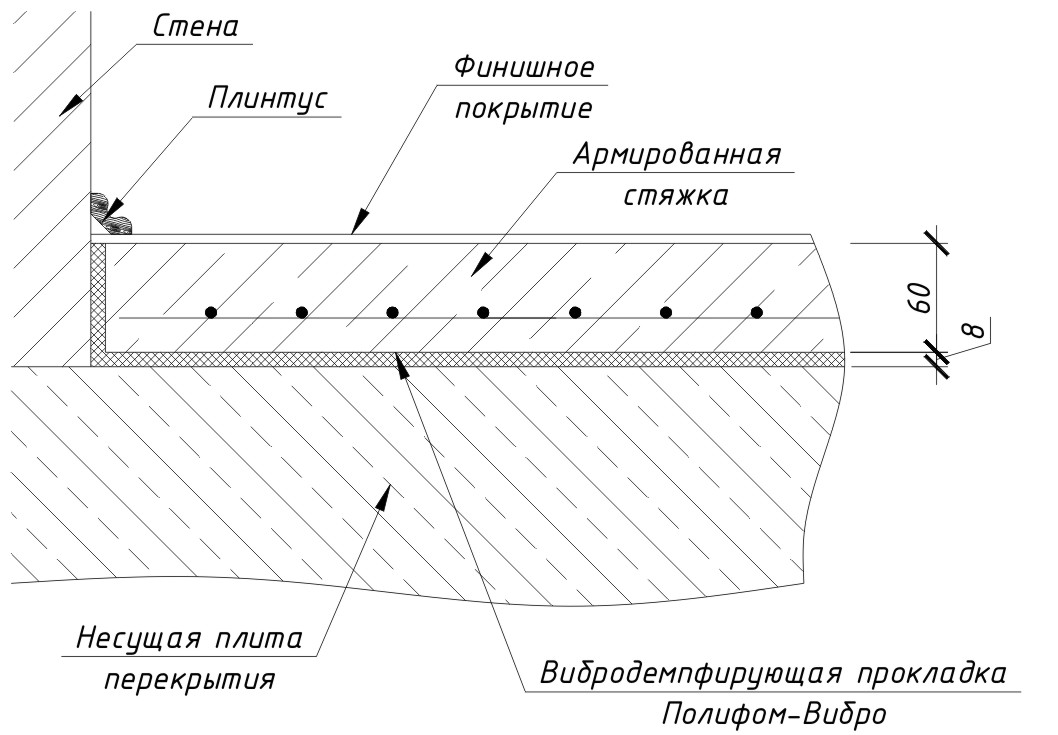

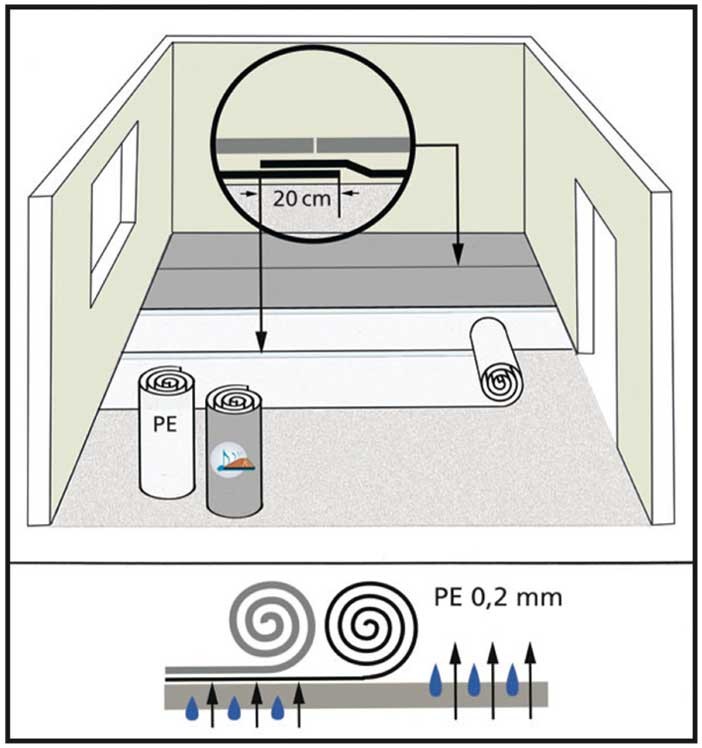

Scheme of concrete floor screed.Preparing the surface of a concrete floor involves checking it for bumps and depressions. The former can be removed by carefully beating them off with a hammer, while chips or cracks can be repaired with concrete mortar. Particular attention should be paid to differences in height, which should not be more than 3 mm. In order to eliminate such errors, the surface can be leveled by installing a thin screed, which you can prepare yourself using water, cement and sand. You can resort to pouring a self-leveling mixture. Before starting the laying process after pouring such a mixture, you should wait 3 days. Return to the table of contents</a>Laying the underlay Before , it is necessaryprotect the floor surface with underlays, of which there should be two, each with its own purpose. The materials should have vapor and sound insulation qualities. Scheme of the substrate for the laminate.Polyethylene film can be used as the first substrate. It is unacceptable to use low-quality material, so do not save on the price. It is recommended to use a film with a thickness of 200 microns or more. This is the layer that will be able to guarantee protection from moisture penetration. The polyethylene film should be laid on a leveled concrete floor so that there are no gaps between the joints of the sheets, so it is necessary to ensure an overlap, fastening the sheets with construction tape. The overlap width should not be less than 20 cm. The second layer of the substrate is necessary for sound insulation and softening. Laying should be done on top of the polyethylene. Installation should be done end to end, the strips should also be reinforced with construction tape. This layer can be a material based on polymers or cork. Return to the table of contents</a>

Scheme of the substrate for the laminate.Polyethylene film can be used as the first substrate. It is unacceptable to use low-quality material, so do not save on the price. It is recommended to use a film with a thickness of 200 microns or more. This is the layer that will be able to guarantee protection from moisture penetration. The polyethylene film should be laid on a leveled concrete floor so that there are no gaps between the joints of the sheets, so it is necessary to ensure an overlap, fastening the sheets with construction tape. The overlap width should not be less than 20 cm. The second layer of the substrate is necessary for sound insulation and softening. Laying should be done on top of the polyethylene. Installation should be done end to end, the strips should also be reinforced with construction tape. This layer can be a material based on polymers or cork. Return to the table of contents</a>

Laminate laying technology

Laying laminate flooring can be done in several waysmethods: lengthwise, crosswise or diagonally. If you intend to do the work yourself, but do not have sufficient skills in conducting such a process, it is recommended to mount the boards parallel to the wall. This will eliminate the need for lengthy adjustment of the boards to size. Scheme of laying laminate on concrete screed.When laying laminate on a concrete floor, it is necessary to use bars, which can be plastic or wooden. They should be placed between the walls and the covering, thus creating a temperature gap that will prevent deformation of the board when external conditions change. The width of the grooves is determined by the thickness of the bars and should be equal to the limit of 8-10 mm. Laying the laminate in the first row begins with a solid board, but the installation of the second row must begin with half a board, which will provide the effect of brickwork and evenly distribute the load over the entire surface. If the laying process is carried out using boards with a Lock type lock, then to connect the panels, it will be enough to bring the products of the first and second rows together, and then carefully tap them with a hammer with a rubber tip. When the panel has a Click lock, there is no need to tap them: the board to be joined must be inserted into the laid product at an angle of 25-40 ° and lowered until a characteristic click is obtained. All subsequent rows must be installed according to the already described scheme.

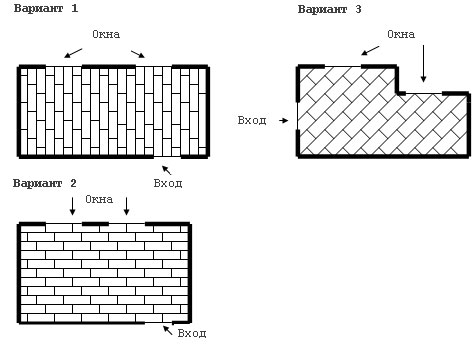

Scheme of laying laminate on concrete screed.When laying laminate on a concrete floor, it is necessary to use bars, which can be plastic or wooden. They should be placed between the walls and the covering, thus creating a temperature gap that will prevent deformation of the board when external conditions change. The width of the grooves is determined by the thickness of the bars and should be equal to the limit of 8-10 mm. Laying the laminate in the first row begins with a solid board, but the installation of the second row must begin with half a board, which will provide the effect of brickwork and evenly distribute the load over the entire surface. If the laying process is carried out using boards with a Lock type lock, then to connect the panels, it will be enough to bring the products of the first and second rows together, and then carefully tap them with a hammer with a rubber tip. When the panel has a Click lock, there is no need to tap them: the board to be joined must be inserted into the laid product at an angle of 25-40 ° and lowered until a characteristic click is obtained. All subsequent rows must be installed according to the already described scheme. Laminate flooring installation options.It is necessary to lay the laminate in the last row, cutting the boards to size using a hacksaw with fine teeth, which can be replaced with an electric jigsaw. In the process of carrying out work, spacer wedges should be mounted at the end of each row. The resulting space should then be covered with a baseboard. It is necessary to lay the laminate, placing the boards along the incidence of light from the window, this will hide the joints between the panels. Work should be started from the far corner of the room. Before arranging the floor, the material should be allowed to acclimatize, for this it must be brought into the room in which the work is supposed to be carried out, and left for two days. The process of laying can also be carried out using an adhesive method, which is becoming less and less popular today, for several reasons. The first of them is that the material cannot be re-installed after laying. Such a need arises when communications under the covering need repair. In addition, the adhesive method will not allow partial repair of the covering, since dismantling is accompanied by damage and breakage of the boards due to their strong attachment to each other.

Laminate flooring installation options.It is necessary to lay the laminate in the last row, cutting the boards to size using a hacksaw with fine teeth, which can be replaced with an electric jigsaw. In the process of carrying out work, spacer wedges should be mounted at the end of each row. The resulting space should then be covered with a baseboard. It is necessary to lay the laminate, placing the boards along the incidence of light from the window, this will hide the joints between the panels. Work should be started from the far corner of the room. Before arranging the floor, the material should be allowed to acclimatize, for this it must be brought into the room in which the work is supposed to be carried out, and left for two days. The process of laying can also be carried out using an adhesive method, which is becoming less and less popular today, for several reasons. The first of them is that the material cannot be re-installed after laying. Such a need arises when communications under the covering need repair. In addition, the adhesive method will not allow partial repair of the covering, since dismantling is accompanied by damage and breakage of the boards due to their strong attachment to each other. Scheme of laying laminate using adhesive method.If you decide to lay the laminate in the above-described way, then the end and shared sides of the products must be carefully treated with adhesive before joining. Regardless of the type of locking system present on the panels, the laminate can be laid using the row assembly method with subsequent joining of the finished rows. This indicates that it is initially necessary to assemble the entire first row, then the entire second, and then connect them. The floor can be installed by laying individual planks, this is suitable for those cases when the master intends to do the work independently, without resorting to outside help. However, some are sure that it is much easier and more convenient to assemble the laminate in rows. Laying the laminate should not be accompanied by hammer blows on the laminated panels themselves. Sufficient joint density can be ensured by hitting the panels through a block, for this you can also use unnecessary trimming of the coating itself. In order to lay the first row of panels, the ridge of the products must first be cut off. The corrected side should be directed towards the wall, while the lock of the planks should be facing the master. In order to begin forming the first row, it is not necessary to be close to the wall.

Scheme of laying laminate using adhesive method.If you decide to lay the laminate in the above-described way, then the end and shared sides of the products must be carefully treated with adhesive before joining. Regardless of the type of locking system present on the panels, the laminate can be laid using the row assembly method with subsequent joining of the finished rows. This indicates that it is initially necessary to assemble the entire first row, then the entire second, and then connect them. The floor can be installed by laying individual planks, this is suitable for those cases when the master intends to do the work independently, without resorting to outside help. However, some are sure that it is much easier and more convenient to assemble the laminate in rows. Laying the laminate should not be accompanied by hammer blows on the laminated panels themselves. Sufficient joint density can be ensured by hitting the panels through a block, for this you can also use unnecessary trimming of the coating itself. In order to lay the first row of panels, the ridge of the products must first be cut off. The corrected side should be directed towards the wall, while the lock of the planks should be facing the master. In order to begin forming the first row, it is not necessary to be close to the wall. Scheme of laying laminate near doorways.After the second strip has been assembled and attached to the first row of products, it is permissible to place the starting floor elements against the wall, installing spacer wedges around the perimeter. Factory spacers can be used as wedges, which can provide a more accurate distance. These elements should be spaced approximately 25 cm apart. It is necessary to ensure that the expansion gap is smaller than the width of the baseboard, since the latter will cover the groove. The material should be placed under the door frame that leads into the room in such a way that there is no gap between the jambs and the floor. To do this, both frame posts must be sawed from below to a thickness equal to the corresponding indicator for the laminate. In those places where the floor and the pipeline intersect, it is necessary to make holes in the panel using a feather drill or jigsaw with a diameter that exceeds the same pipe dimensions by 1 cm or more. The rules suggest increasing the radius by 1 cm, which requires the need to arrange an indentation, generally equal to 1 cm around the circumference of the entire pipe. But, as practice shows, such an impressive gap has a very unattractive appearance, and even after it is successfully masked with a sealant, it does not look good.

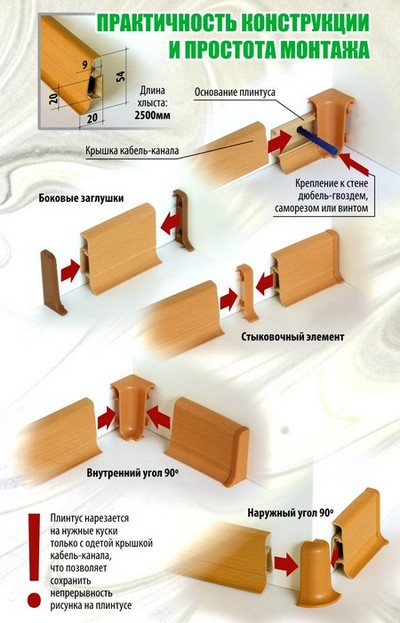

Scheme of laying laminate near doorways.After the second strip has been assembled and attached to the first row of products, it is permissible to place the starting floor elements against the wall, installing spacer wedges around the perimeter. Factory spacers can be used as wedges, which can provide a more accurate distance. These elements should be spaced approximately 25 cm apart. It is necessary to ensure that the expansion gap is smaller than the width of the baseboard, since the latter will cover the groove. The material should be placed under the door frame that leads into the room in such a way that there is no gap between the jambs and the floor. To do this, both frame posts must be sawed from below to a thickness equal to the corresponding indicator for the laminate. In those places where the floor and the pipeline intersect, it is necessary to make holes in the panel using a feather drill or jigsaw with a diameter that exceeds the same pipe dimensions by 1 cm or more. The rules suggest increasing the radius by 1 cm, which requires the need to arrange an indentation, generally equal to 1 cm around the circumference of the entire pipe. But, as practice shows, such an impressive gap has a very unattractive appearance, and even after it is successfully masked with a sealant, it does not look good. Scheme for installing plastic skirting boards on laminate.Moreover, it is left to compensate for the movements of the entire floor. In a small area near the pipes, the boards will naturally not shift so intensively. In order to give the floor an aesthetic appearance, the connection of individual boards in the last row is carried out using a special bracket, which is called a clamp. In the packaging from under the laminate, the master will be able to find detailed instructions for its installation. If there are interesting architectural objects in the room, such as a large fireplace or a balcony above the bay window, then the distribution of the floor rows must begin from their central axis. To carry out work on laying the laminate, you should prepare the following tools and materials:

Scheme for installing plastic skirting boards on laminate.Moreover, it is left to compensate for the movements of the entire floor. In a small area near the pipes, the boards will naturally not shift so intensively. In order to give the floor an aesthetic appearance, the connection of individual boards in the last row is carried out using a special bracket, which is called a clamp. In the packaging from under the laminate, the master will be able to find detailed instructions for its installation. If there are interesting architectural objects in the room, such as a large fireplace or a balcony above the bay window, then the distribution of the floor rows must begin from their central axis. To carry out work on laying the laminate, you should prepare the following tools and materials:

- a hammer;

- polyethylene film;

- hacksaw;

- building scotch;

- laminate.

The installation work will not be difficult to carry out,the main thing is not to rush. In addition, if you do not have enough skills, then for the first time it is preferable to mount the boards along the light from the window and without using glue. The method where the boards are fastened only with a locking connection helps to arrange the so-called floating floor, while the use of glue connects the covering quite rigidly.