In recent decades, a widespread specieslaminate flooring became the standard. Initially, it was intended to reproduce the appearance of parquet, but over time it gained popularity due to its relatively low cost, ease of assembly, undemanding maintenance, and variety of designs. Concrete screed under laminate.Structurally, laminate is a prefabricated covering, the panels of which, when connected to each other, form a flat floor. The advantage of laminate is the structure of several layers, each of which performs its own function:

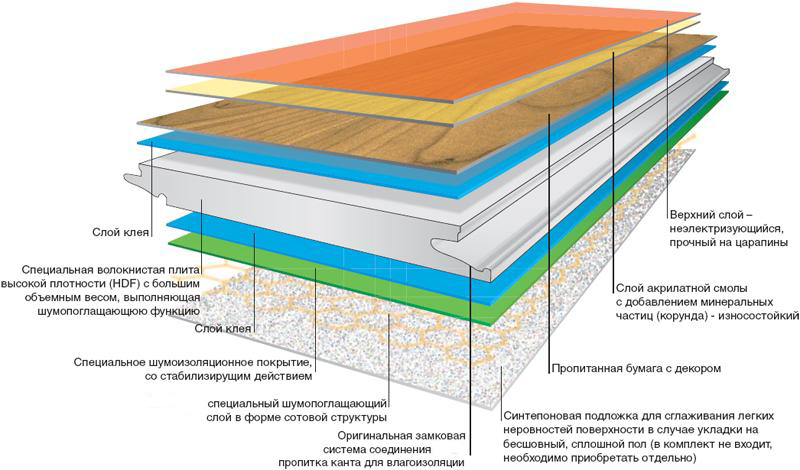

Concrete screed under laminate.Structurally, laminate is a prefabricated covering, the panels of which, when connected to each other, form a flat floor. The advantage of laminate is the structure of several layers, each of which performs its own function:

Laminate structure diagram.The advantages of laminate flooring include its extraordinary ease of assembly. Individual panels are simply connected to each other using special locks, they are not attached to the floor. This makes it possible to disassemble the flooring in case of emergency without damaging it. Laminate does not require additional treatment after proper installation (grinding, varnish coating, etc.), and cleaning such a floor is extremely simple. There are also disadvantages. For example, low water resistance. Of course, a modern product will withstand prolonged contact with water, but it is still undesirable to allow this. Such a floor, of course, can be washed, but carefully, using special products. The disadvantages include the fact that fiberboard is an excellent resonator, steps and falling hard objects will respond with a fairly loud sound. You can quickly get used to this or use special sound-insulating pads.

Laminate structure diagram.The advantages of laminate flooring include its extraordinary ease of assembly. Individual panels are simply connected to each other using special locks, they are not attached to the floor. This makes it possible to disassemble the flooring in case of emergency without damaging it. Laminate does not require additional treatment after proper installation (grinding, varnish coating, etc.), and cleaning such a floor is extremely simple. There are also disadvantages. For example, low water resistance. Of course, a modern product will withstand prolonged contact with water, but it is still undesirable to allow this. Such a floor, of course, can be washed, but carefully, using special products. The disadvantages include the fact that fiberboard is an excellent resonator, steps and falling hard objects will respond with a fairly loud sound. You can quickly get used to this or use special sound-insulating pads.

Conditions for laying laminate

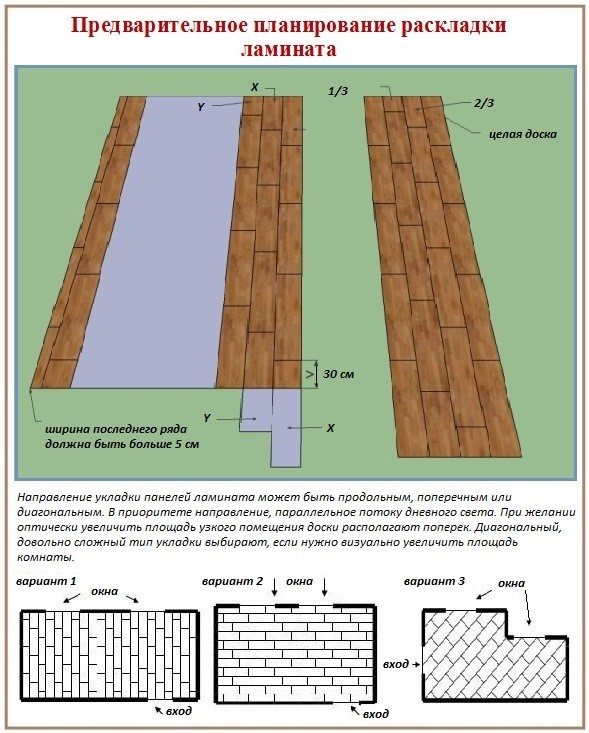

To obtain a durable and level floor, the following conditions must be met: Laminate flooring installation options.

Laminate flooring installation options.

Return to Contents</a>

Preparatory work

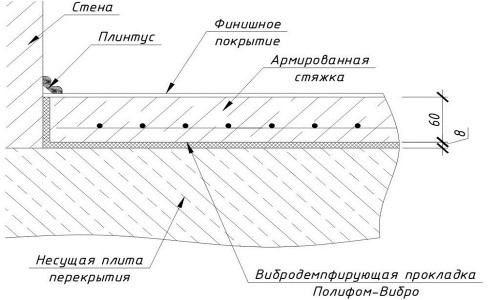

Scheme of the device of a warm floor under the laminate.Before laying laminate on a concrete screed, it is necessary to ensure that the base is uniform and free of defects. Laminate is laid on a new screed only after it has completely dried (a month after pouring). If the coating is changed on an already finished screed, then it is necessary to ensure its integrity. In case of small irregularities and cracks, the concrete can be filled with a self-leveling mixture. If the damage is significant, it is better to make the screed again. The screed can be concrete or cement-sand. Cement is used in both cases, the difference is in the base: in the first case, it is crushed stone screenings, in the second - sand. Both options are quite suitable for laying laminate. The preparation of the solution also differs slightly: for a cement-sand screed, 4 parts of sand are taken to 1 part of cement (grade 400), for concrete - 5-7 parts of screenings and 1 part of cement.

Scheme of the device of a warm floor under the laminate.Before laying laminate on a concrete screed, it is necessary to ensure that the base is uniform and free of defects. Laminate is laid on a new screed only after it has completely dried (a month after pouring). If the coating is changed on an already finished screed, then it is necessary to ensure its integrity. In case of small irregularities and cracks, the concrete can be filled with a self-leveling mixture. If the damage is significant, it is better to make the screed again. The screed can be concrete or cement-sand. Cement is used in both cases, the difference is in the base: in the first case, it is crushed stone screenings, in the second - sand. Both options are quite suitable for laying laminate. The preparation of the solution also differs slightly: for a cement-sand screed, 4 parts of sand are taken to 1 part of cement (grade 400), for concrete - 5-7 parts of screenings and 1 part of cement. Laminate flooring installation diagram.Before pouring, it is necessary to install beacons, for which a special profile is suitable. Its thickness depends on the desired height of the screed. The distance between the profiles should be less than the rule (by 10-15 cm), to have freedom of movement when pulling the solution along the beacons. The latter must dry for 24 hours, after which the screed can be poured. Another day later, the poured screed must be leveled with a float. Drying time takes from 7 to 21 days. Let it be longer, excess moisture is not necessary for laminate. A floor with an old and not quite even screed can be leveled with a special mixture, but only if the differences are no more than 2 cm. To do this, draw a line along the perimeter of the room at floor level. The mixture is prepared according to the instructions and spread over the floor with a spatula. To prevent the presence of air bubbles, you can use a roller with a needle surface (on a long handle). The entire surface must be poured at one time. After finishing the work, the floor should dry for at least three days. Return to contents</a>

Laminate flooring installation diagram.Before pouring, it is necessary to install beacons, for which a special profile is suitable. Its thickness depends on the desired height of the screed. The distance between the profiles should be less than the rule (by 10-15 cm), to have freedom of movement when pulling the solution along the beacons. The latter must dry for 24 hours, after which the screed can be poured. Another day later, the poured screed must be leveled with a float. Drying time takes from 7 to 21 days. Let it be longer, excess moisture is not necessary for laminate. A floor with an old and not quite even screed can be leveled with a special mixture, but only if the differences are no more than 2 cm. To do this, draw a line along the perimeter of the room at floor level. The mixture is prepared according to the instructions and spread over the floor with a spatula. To prevent the presence of air bubbles, you can use a roller with a needle surface (on a long handle). The entire surface must be poured at one time. After finishing the work, the floor should dry for at least three days. Return to contents</a>

Materials and tools that will be needed when laying the laminate

Before laying laminate on a screed, you need to make sure you have the right tools. You can buy ready-made kits or collect everything you need separately. In any case, you will need: Scheme of laying laminate with corner lock.

Scheme of laying laminate with corner lock.

- tools for marking, namely pencil, gon, roulette (5-7 m);

- Hammer (to ensure the density of docking panels);

- jigsaw or hacksaw with small teeth (for the corners of the skirting you will need a stool and an angled);

- perforator;

- podbivochny bar (better plastic) to mitigate the impact;

- Limit wedges (to fix the distance between the structure and the wall);

- Staple of metal (for padding the end panel).

To install laminate flooring you will need: The amount of displacement of panels in adjacent rows relative to each other.

The amount of displacement of panels in adjacent rows relative to each other.

- laminate panels;

- plinth;

- corners for plinth;

- Pipe outlines (to hide gaps around the pipe);

- nails (to hide interior crossings or a flexible docking profile);

- substrate (cork, made of foamed polypropylene, mat from sawdust of coniferous trees, expanded polystyrene);

- polyethylene film.

Return to Contents</a>

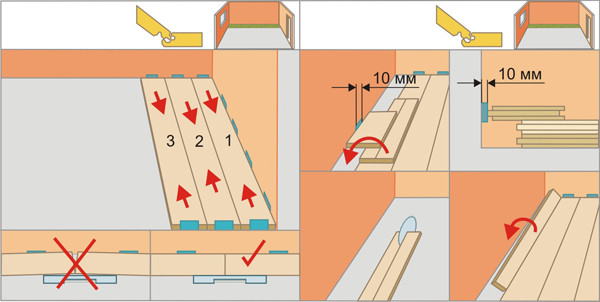

The order of assembly of laminated panels

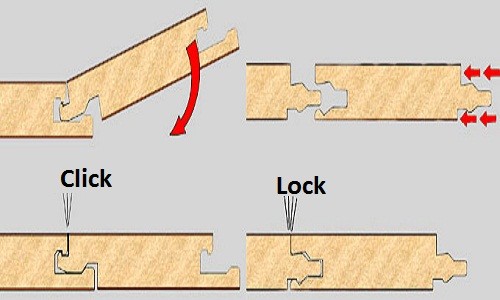

Before starting work on laying laminate flooring,the floor screed must be thoroughly vacuumed. Then lay the polyethylene film, after which - the selected type of underlay. For better tightness, the rows are fastened together with adhesive tape. It is better to lay the floor not at once, but in separate sections to avoid unnecessary contamination. Before laying the first row of boards, you need to install spacer wedges around the perimeter to provide a gap. Diagram of the difference between "Click" and "Lock" type locks.The same should be done around all obstacles (pipes, communications, etc.). Laminate flooring can be laid in several ways: with glue or locking joints (there are two types of locks). The panels are inserted into each other at an angle, tightly adjusted, and then lowered. For better insulation, the locks are glued with sealant. First, the side locks are attached, then connected to the row. Each subsequent row is laid with a shift of 20 cm up to ½ the length of the panel. It is advisable to start laying from the location of the heating devices. To carefully saw the panel and place it around the pipe, you need to drill a hole of a larger diameter and cut the panel at the pipe level. Then the panels are assembled in the usual order, and the gaps are covered with trims. To complete the row, the last panel is adjusted to size. To secure the last row, you may have to make a longitudinal cut from the wall side. It is very important to take the correct measurements. The laminate panel is attached in the same way, but you can also use a special Z-shaped bracket. The final stage is the installation of the baseboard. Here, too, there is a wide choice of installation using dowels, screws or special fasteners. There are designs with a cable channel, where it is convenient to hide the wires. After completing the work, you can start using the floor immediately, except for installation using glue. In this case, additional drying time is needed.

Diagram of the difference between "Click" and "Lock" type locks.The same should be done around all obstacles (pipes, communications, etc.). Laminate flooring can be laid in several ways: with glue or locking joints (there are two types of locks). The panels are inserted into each other at an angle, tightly adjusted, and then lowered. For better insulation, the locks are glued with sealant. First, the side locks are attached, then connected to the row. Each subsequent row is laid with a shift of 20 cm up to ½ the length of the panel. It is advisable to start laying from the location of the heating devices. To carefully saw the panel and place it around the pipe, you need to drill a hole of a larger diameter and cut the panel at the pipe level. Then the panels are assembled in the usual order, and the gaps are covered with trims. To complete the row, the last panel is adjusted to size. To secure the last row, you may have to make a longitudinal cut from the wall side. It is very important to take the correct measurements. The laminate panel is attached in the same way, but you can also use a special Z-shaped bracket. The final stage is the installation of the baseboard. Here, too, there is a wide choice of installation using dowels, screws or special fasteners. There are designs with a cable channel, where it is convenient to hide the wires. After completing the work, you can start using the floor immediately, except for installation using glue. In this case, additional drying time is needed.