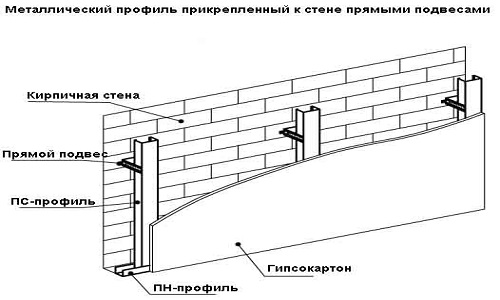

Drywall is a sheet materiala building material with many positive qualities. Its smooth and even surface allows you to easily build plasterboard walls that will fit perfectly into any interior. Scheme of installation of plasterboard on metalprofile. Plasterboard walls are strong enough and provide sound insulation. The simplicity of the manufacturing process of such walls is explained by the high technological properties of the material. Plasterboard is easy to cut, drill and cover with any finishing elements.

Scheme of installation of plasterboard on metalprofile. Plasterboard walls are strong enough and provide sound insulation. The simplicity of the manufacturing process of such walls is explained by the high technological properties of the material. Plasterboard is easy to cut, drill and cover with any finishing elements.

Gypsum wall constructions

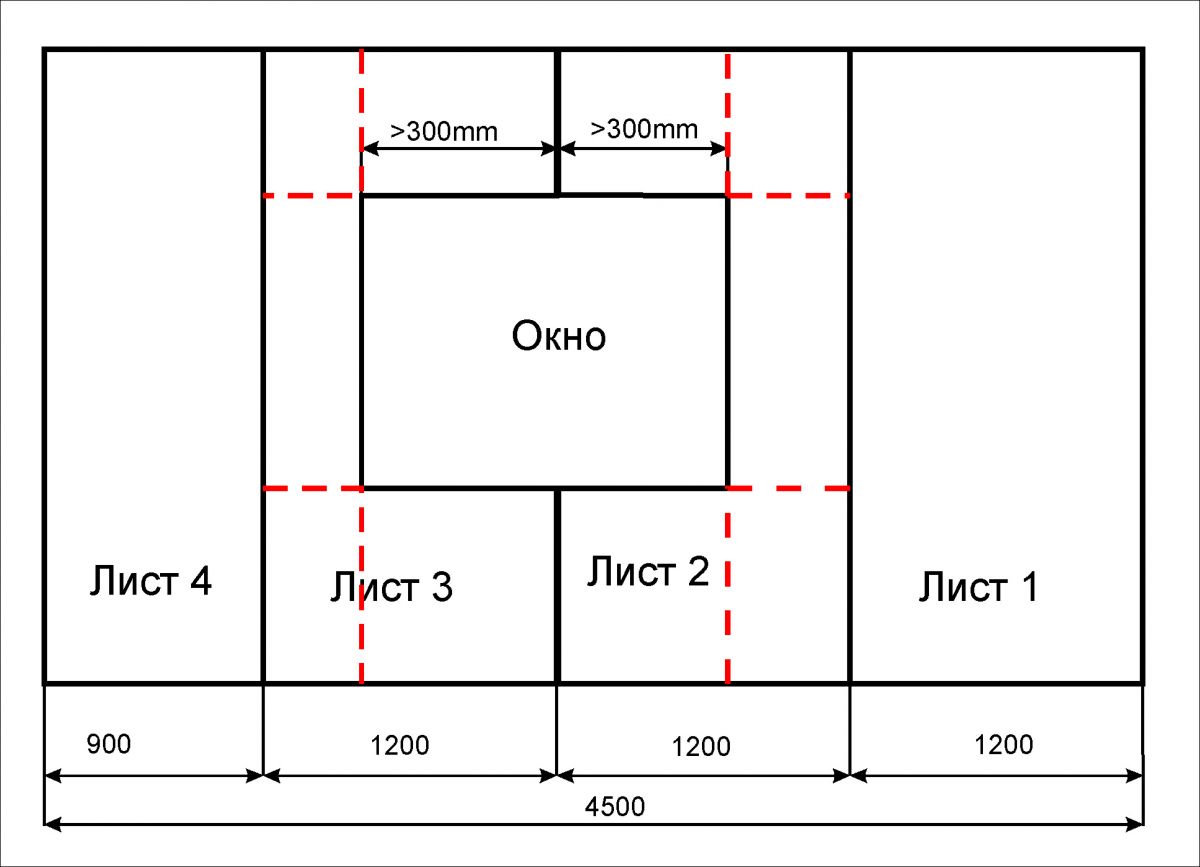

Scheme for calculating plasterboard for a wall.Plasterboard walls are divided into two main types: a partition and a ready-made wall covered with plasterboard. A plasterboard partition is an independent interior wall designed to divide a room into rooms or to zone the space. A plasterboard wall, installed as an additional layer on a ready-made concrete or brick wall, is usually designed for insulation, soundproofing or interior decoration of the room. The partition design includes a double-sided frame, inside which the filler is placed. On both sides, the frame is covered with plasterboard sheets, on top of which external coatings are applied. The partition must have sufficient mechanical strength, sound insulation and the ability to install doors and windows (if necessary). Spatially, it can only be attached by its ribs:

Scheme for calculating plasterboard for a wall.Plasterboard walls are divided into two main types: a partition and a ready-made wall covered with plasterboard. A plasterboard partition is an independent interior wall designed to divide a room into rooms or to zone the space. A plasterboard wall, installed as an additional layer on a ready-made concrete or brick wall, is usually designed for insulation, soundproofing or interior decoration of the room. The partition design includes a double-sided frame, inside which the filler is placed. On both sides, the frame is covered with plasterboard sheets, on top of which external coatings are applied. The partition must have sufficient mechanical strength, sound insulation and the ability to install doors and windows (if necessary). Spatially, it can only be attached by its ribs:

- on the sides - against the wall;

- from below - to the floor;

- from above - to the ceiling.

The partition frame must perform a power functionand can be made of metal profiles or wooden beams. An additional wall made of plasterboard is installed on a finished wall and does not bear a power load. Its task is to improve the thermal insulation and sound insulation properties of the walls (usually in contact with the external environment). Such a wall has a one-sided frame filled with heat insulator and plasterboard sheathing. The frame performs only a mounting function and can be made of lightweight profiles or wooden beams. Return to contents</a>

Selection of suitable materials

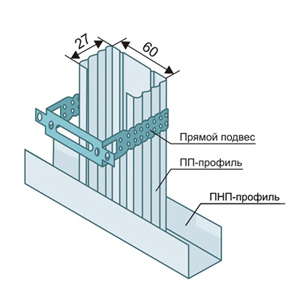

Assembly diagram of profiles for plasterboard installation.Plasterboard is sold in standard sheets 120 cm wide, 250 and 300 cm long, 6, 9 and 12.5 mm thick. Conventional plasterboard of the GKL type consists of two sheets of thick cardboard with a hard gypsum mass between them. Plasterboard of the GKLV type is produced, which has increased moisture resistance. Due to the use of special fillers, plasterboard acquires improved heat resistance (like GVL with fibrous filler), increased sound insulation or acoustic properties. Most often, plasterboard of the GKL type is used, but in rooms with high humidity, plasterboard of the GVL type is recommended. The frame of the partitions is made of metal profiles. For vertical placement, rack profiles (C-shaped) of the PS type are used. The standard sizes are 50x50, 65x50, 75x50 and 100x50 mm (the first digit is the width, the second is the height of the sheet) and are available in lengths of 3 and 4 m. Guide profiles (U-shaped) of the PN type are attached horizontally. The standard sizes are 50x40, 65x40, 75x40 and 100x50 mm. The profiles are available in lengths of 3 m. When making a wooden frame, you can use a wooden beam of 40x40 or 50x50 mm. For the frame of an additional wall, you can use the same profiles as for partitions, but it is recommended to use lightweight profiles with a wall thickness of 0.55-0.8 mm. It is enough to install the following profiles: rack - CD (PS) 27x60; guides - UD (PN) 27x28. For a wooden frame, beams of 30x40 or 40x40 mm are suitable. Return to contents</a>

Assembly diagram of profiles for plasterboard installation.Plasterboard is sold in standard sheets 120 cm wide, 250 and 300 cm long, 6, 9 and 12.5 mm thick. Conventional plasterboard of the GKL type consists of two sheets of thick cardboard with a hard gypsum mass between them. Plasterboard of the GKLV type is produced, which has increased moisture resistance. Due to the use of special fillers, plasterboard acquires improved heat resistance (like GVL with fibrous filler), increased sound insulation or acoustic properties. Most often, plasterboard of the GKL type is used, but in rooms with high humidity, plasterboard of the GVL type is recommended. The frame of the partitions is made of metal profiles. For vertical placement, rack profiles (C-shaped) of the PS type are used. The standard sizes are 50x50, 65x50, 75x50 and 100x50 mm (the first digit is the width, the second is the height of the sheet) and are available in lengths of 3 and 4 m. Guide profiles (U-shaped) of the PN type are attached horizontally. The standard sizes are 50x40, 65x40, 75x40 and 100x50 mm. The profiles are available in lengths of 3 m. When making a wooden frame, you can use a wooden beam of 40x40 or 50x50 mm. For the frame of an additional wall, you can use the same profiles as for partitions, but it is recommended to use lightweight profiles with a wall thickness of 0.55-0.8 mm. It is enough to install the following profiles: rack - CD (PS) 27x60; guides - UD (PN) 27x28. For a wooden frame, beams of 30x40 or 40x40 mm are suitable. Return to contents</a>

Step-by-Step Instruction: Editing the Partition Frame

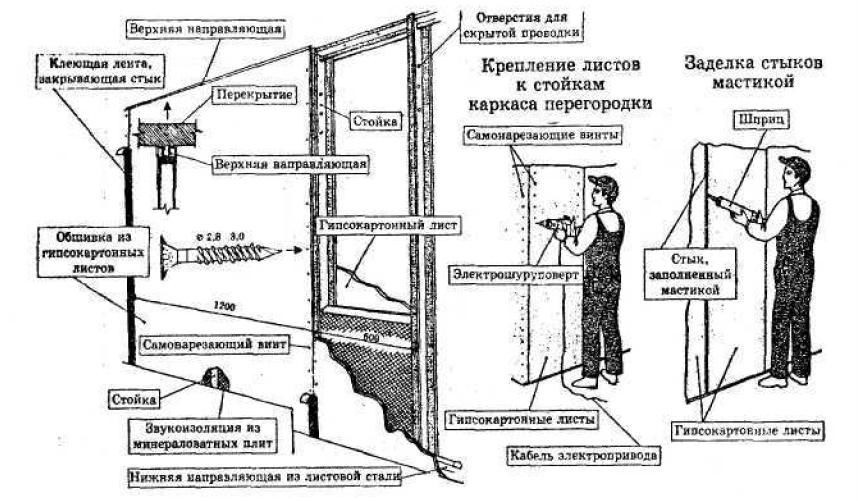

Installation diagram of a plasterboard partition.Installing a plasterboard partition yourself begins with assembling the frame. First, the wall installation is marked out: strictly vertical lines are drawn along the walls using a plumb line (a mark is made at the top and beaten off using painted construction twine); then they are connected along the ceiling and floor. The first side of the frame and plasterboard sheets are laid out horizontally on the floor. The rack and guide profiles are cut to size. If it is not possible to select a profile of the same length, then it is connected from sections using a U-shaped standard connector of 40-50 mm or metal strips. The connection must be rigid and strong. Holes for fastening are drilled in the guide profiles at a distance of 40-50 cm from each other. The plasterboard sheets are cut to actual dimensions, taking into account the openings. The guide profile is applied to the ceiling along the marked line and marks are made on the ceiling through the holes. Using a hammer drill or electric drill, drill holes in the ceiling with a diameter of 6-8 mm according to the marks and install dowels in them. The profiles are fastened in the dowels with self-tapping screws. The guide profiles on the walls and floor are installed in a similar manner. Before fixing the profile, a sealing tape is glued to its outer surface. When installing the profile on the floor, it is necessary to take into account the location of the doorway, where the profile is not installed at the bottom. The rack profiles are installed strictly vertically and must be of the same length. First, the profiles defining the boundaries of the doorway are fixed. They are inserted into the guide profiles at the bottom and top and fixed with self-tapping screws. The base of the profile should be directed to the front side of the future partition. Then other rack profiles are fixed strictly in parallel, evenly distributed between the wall and the installed profiles with a step of 50-60 cm. Between the vertical racks, horizontal lintels are mounted, cut to the actual size from the PS profile. First, the lintel is fixed, defining the upper boundary of the doorway. Fastening between the vertical racks and the lintel is carried out as follows. At the end of the lintel, a 20-25 mm long cut is made with metal scissors along the profile bend line. The side sections are bent to the sides. The size of the fastening area must be taken into account when cutting the lintels. The bent petals and the continuation of the profile base are fixed to the surface of the racks with flea screws. The lintels are fixed along the entire frame strictly horizontally with a step of about 60 cm. The lattice of the first side of the frame is formed. The second side of the frame is mounted in a similar manner at a distance equal to the thickness of the partition minus the thickness of two sheets of plasterboard. Between the two sides of the frame, transverse crossbars are installed from sections of the rack profile. Such crossbars are first fastened at the corners of the doorway; then evenly across the entire frame at a distance of 1-1.2 m from each other. Return to contents</a>

Installation diagram of a plasterboard partition.Installing a plasterboard partition yourself begins with assembling the frame. First, the wall installation is marked out: strictly vertical lines are drawn along the walls using a plumb line (a mark is made at the top and beaten off using painted construction twine); then they are connected along the ceiling and floor. The first side of the frame and plasterboard sheets are laid out horizontally on the floor. The rack and guide profiles are cut to size. If it is not possible to select a profile of the same length, then it is connected from sections using a U-shaped standard connector of 40-50 mm or metal strips. The connection must be rigid and strong. Holes for fastening are drilled in the guide profiles at a distance of 40-50 cm from each other. The plasterboard sheets are cut to actual dimensions, taking into account the openings. The guide profile is applied to the ceiling along the marked line and marks are made on the ceiling through the holes. Using a hammer drill or electric drill, drill holes in the ceiling with a diameter of 6-8 mm according to the marks and install dowels in them. The profiles are fastened in the dowels with self-tapping screws. The guide profiles on the walls and floor are installed in a similar manner. Before fixing the profile, a sealing tape is glued to its outer surface. When installing the profile on the floor, it is necessary to take into account the location of the doorway, where the profile is not installed at the bottom. The rack profiles are installed strictly vertically and must be of the same length. First, the profiles defining the boundaries of the doorway are fixed. They are inserted into the guide profiles at the bottom and top and fixed with self-tapping screws. The base of the profile should be directed to the front side of the future partition. Then other rack profiles are fixed strictly in parallel, evenly distributed between the wall and the installed profiles with a step of 50-60 cm. Between the vertical racks, horizontal lintels are mounted, cut to the actual size from the PS profile. First, the lintel is fixed, defining the upper boundary of the doorway. Fastening between the vertical racks and the lintel is carried out as follows. At the end of the lintel, a 20-25 mm long cut is made with metal scissors along the profile bend line. The side sections are bent to the sides. The size of the fastening area must be taken into account when cutting the lintels. The bent petals and the continuation of the profile base are fixed to the surface of the racks with flea screws. The lintels are fixed along the entire frame strictly horizontally with a step of about 60 cm. The lattice of the first side of the frame is formed. The second side of the frame is mounted in a similar manner at a distance equal to the thickness of the partition minus the thickness of two sheets of plasterboard. Between the two sides of the frame, transverse crossbars are installed from sections of the rack profile. Such crossbars are first fastened at the corners of the doorway; then evenly across the entire frame at a distance of 1-1.2 m from each other. Return to contents</a>

Installation of drywall by own hands

Types of plasterboard edges.The final stage begins with the installation of plasterboard sheets on the first side of the frame. First, the entire sheet is attached, starting from the upper corner. Fastening is done with self-tapping screws. It is recommended to pre-drill holes in the places of fastening according to the diameter of the screw. The distance between the screws is 10-25 cm. A gap of about 10-15 mm is left at the bottom between the sheet and the floor. In this way, the entire side of the first frame is faced. Then the space between the two sides of the frame is filled with filler. Most often, mineral wool is used for this purpose. Sheet or tile foam can be used. After the frame is tightly filled, the second side of the frame is faced with plasterboard in the same way as the first side. The surface of the partition is puttied on both sides. A strip of mounting mesh is first glued to the joints of the plasterboard sheets. Then, starting putty is applied to the joints and places of fastening with screws. After it dries, the finishing putty is applied to the entire surface of the partition on both sides. Return to contents</a>

Types of plasterboard edges.The final stage begins with the installation of plasterboard sheets on the first side of the frame. First, the entire sheet is attached, starting from the upper corner. Fastening is done with self-tapping screws. It is recommended to pre-drill holes in the places of fastening according to the diameter of the screw. The distance between the screws is 10-25 cm. A gap of about 10-15 mm is left at the bottom between the sheet and the floor. In this way, the entire side of the first frame is faced. Then the space between the two sides of the frame is filled with filler. Most often, mineral wool is used for this purpose. Sheet or tile foam can be used. After the frame is tightly filled, the second side of the frame is faced with plasterboard in the same way as the first side. The surface of the partition is puttied on both sides. A strip of mounting mesh is first glued to the joints of the plasterboard sheets. Then, starting putty is applied to the joints and places of fastening with screws. After it dries, the finishing putty is applied to the entire surface of the partition on both sides. Return to contents</a>

Making an additional wall

Installing an additional wall on topThe construction of a capital wall is carried out in much the same way as the manufacture of a partition. First, guide profiles are fixed to the ceiling, floor and walls at a distance of 3-8 cm from the surface of the wall to be closed. The rack profiles are mounted vertically and the lintels horizontally. The step of the horizontal lintels can be increased. The space inside the frame up to the wall is tightly filled with thermal insulation. Before filling and on top, a polyethylene film is laid for waterproofing. Sheets of plasterboard are fixed on top of the frame. Return to contents</a>

Required Tools

Tools for installing plasterboard. When making a plasterboard wall, the following tools are needed:

Tools for installing plasterboard. When making a plasterboard wall, the following tools are needed:

- Screwdriver;

- electric drill;

- perforator;

- putty knife;

- scissors for metal;

- hacksaw;

- screwdriver;

- pliers;

- a hammer;

- mallet;

- knife building;

- roulette;

- line meter.

Plasterboard walls are convenient and easy to make. They provide room redevelopment, insulation, zoning. You can install such walls yourself.