Laminate is often used as a flooringcoatings. Externally - these are narrow panels that are produced on the basis of wood residues, a decorative layer and a protective coating are applied on top, giving the material unique properties. Laying laminate is simple, almost anyone can handle the job. The most important process is the correct . Laminate design diagram.What does the preparatory work consist of? Laminate is a board, for the installation of which it is important to have a flat and solid base, otherwise it will start to crack, the locks will deform. All this will lead to the fact that individual slats will have to be replaced, the floor itself will creak when walking, claps will be heard. The service life of the coating will be reduced, and using it will not bring much pleasure. To avoid all incidents, you cannot do without preparing the base for the laminate. It includes dismantling the old coating, leveling the base base and laying a special underlay in the form of shock-absorbing material. Preparation of the base cannot be neglected, otherwise the flooring will lose all its positive characteristics.

Laminate design diagram.What does the preparatory work consist of? Laminate is a board, for the installation of which it is important to have a flat and solid base, otherwise it will start to crack, the locks will deform. All this will lead to the fact that individual slats will have to be replaced, the floor itself will creak when walking, claps will be heard. The service life of the coating will be reduced, and using it will not bring much pleasure. To avoid all incidents, you cannot do without preparing the base for the laminate. It includes dismantling the old coating, leveling the base base and laying a special underlay in the form of shock-absorbing material. Preparation of the base cannot be neglected, otherwise the flooring will lose all its positive characteristics.

Alignment of concrete base

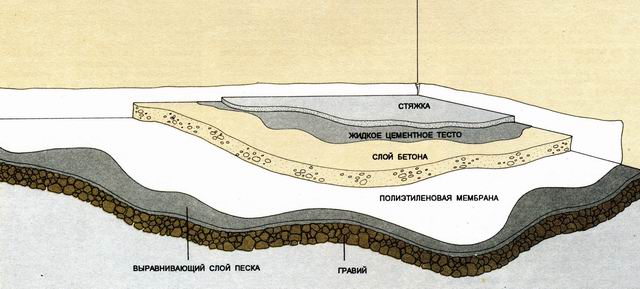

Preparing a concrete floor for laminate flooring includespouring the screed. This is a "wet" construction process that will take a long time; it will take about a month for the base to dry completely. To complete the work, you need to prepare: Scheme of cement floor screed.

Scheme of cement floor screed.

- cement-sand mixture in dry form;

- water for pouring the mixture;

- mixing tank;

- drill, nozzle mixer;

- lighthouses;

- rule;

- building level.

The alignment process itself includes the following stages:

Return to Contents</a>

Aligning the wooden base

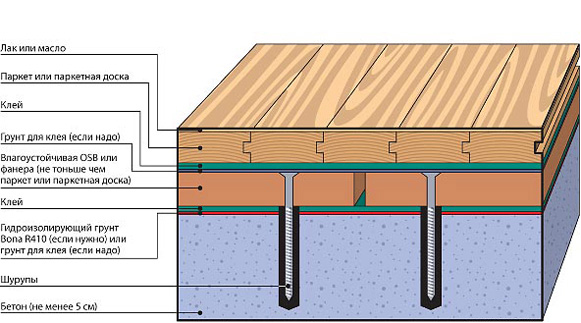

Preparation of the wooden base is carried outmuch easier than concrete floors. So-called wet processes are not used here. Plywood, chipboard, OSB sheets are used for leveling. The base is prepared as follows: Scheme of floor leveling with moisture-resistant plywood.

Scheme of floor leveling with moisture-resistant plywood.

If the floor is very uneven, you will have toinstall the joists, and the plywood will be laid on them. During preparation, the base can be insulated by pouring expanded clay or laying mineral wool between the joists. To do this work, you should prepare:

- plywood plates;

- beams for logs;

- self-tapping screws;

- building level;

- electric jigsaw;

- heater;

- screwdriver.

Return to Contents</a>

Use of leveling mixtures

Preparing the floor for laminate flooring can be done withusing special leveling, i.e. self-leveling mixtures. Beacons are required for laying; they are made from a regular rail or rule. Beacons can be easily made independently, although there are ready-made rails for working with floors on sale. To perform, you need to prepare: Scheme of floor leveling with self-leveling mixture.

Scheme of floor leveling with self-leveling mixture.

- leveling mixture;

- capacity of 20 liters;

- rule;

- special needle roller;

- a mixer and a drill;

- beacons of the chosen type;

- shoes with thorns.

The technology for preparing the base is simple.First, you need to remove the old coating and inspect the surface. Cracks and potholes are filled with a cement-based or putty-based solution. When the base dries, you can begin leveling the base. To do this, pour the dry mixture into a container and add water strictly according to the instructions. Mix the mass with a mixer until smooth. Next, place beacons on the floor and start pouring from the far corner of the room. Roll the mixture with a needle roller; you can only walk on the surface of the base in special studded shoes. About an hour and a half should pass after pouring. If there are any uneven areas, remove them with a rule. When pouring the base with a self-leveling mixture, the following conditions must be met:

Return to Contents</a>

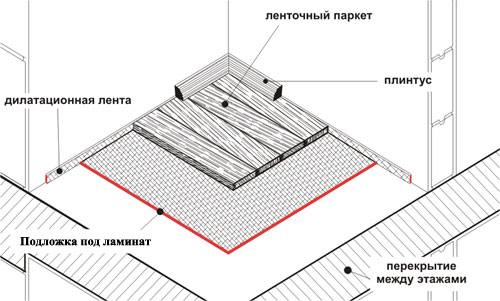

Laying of the substrate under the laminate

Laying film flooring under laminate.When preparing the base, do not forget to use a shock-absorbing underlay. This is a special thin material that allows you to extend the service life of the coating. It acts as a sound-insulating pad, allows you to properly distribute the load on the surface of the board. Today, there are quite a lot of such underlays, but experts highlight 3 main ones:

Laying film flooring under laminate.When preparing the base, do not forget to use a shock-absorbing underlay. This is a special thin material that allows you to extend the service life of the coating. It acts as a sound-insulating pad, allows you to properly distribute the load on the surface of the board. Today, there are quite a lot of such underlays, but experts highlight 3 main ones:

- cork floors;

- foamed polyethylene substrates;

- expanded polystyrene.

Cork backings are naturala material with excellent characteristics. It has a preventive and even therapeutic effect, it is recommended to use it if people with musculoskeletal diseases live in the house. Cork underlay is expensive, although its quality is the best. It is made in the form of slabs or rolls, in some cases this material is combined with bitumen or rubber. During loading, the canvas does not lose its shape, makes it possible to mask small irregularities. Scheme of laying the underlay for laminate.But cork is afraid of moisture, so you should use waterproofing films. Installation is simple, the sheet is glued to the floor or construction tape is used to attach individual elements. Foamed polyethylene substrates are a foamed material that has many advantages, including resistance to mold, fungi, moisture, and chemicals. The base must be carefully leveled, and the durability of this material is not very high. Laying a foamed polyethylene substrate is simple, it is supplied in convenient rolls. It is applied to the base with an overlap, individual strips are glued together with tape. After laying the laminate, all excess that will protrude on the wall surface is cut off. Expanded polystyrene provides adequate sound insulation, is extremely easy to lay, but over time it loses its shape. Experts believe that this particular substrate is universal, can be used for any occasion. Its installation is similar to the previous option. Preparing the base for laminate is an important and responsible process. This concerns not only the floor leveling, but also the use of a special shock-absorbing underlay. In this case, the leveling is carried out depending on the type of base, its general condition.</ ul>

Scheme of laying the underlay for laminate.But cork is afraid of moisture, so you should use waterproofing films. Installation is simple, the sheet is glued to the floor or construction tape is used to attach individual elements. Foamed polyethylene substrates are a foamed material that has many advantages, including resistance to mold, fungi, moisture, and chemicals. The base must be carefully leveled, and the durability of this material is not very high. Laying a foamed polyethylene substrate is simple, it is supplied in convenient rolls. It is applied to the base with an overlap, individual strips are glued together with tape. After laying the laminate, all excess that will protrude on the wall surface is cut off. Expanded polystyrene provides adequate sound insulation, is extremely easy to lay, but over time it loses its shape. Experts believe that this particular substrate is universal, can be used for any occasion. Its installation is similar to the previous option. Preparing the base for laminate is an important and responsible process. This concerns not only the floor leveling, but also the use of a special shock-absorbing underlay. In this case, the leveling is carried out depending on the type of base, its general condition.</ ul>