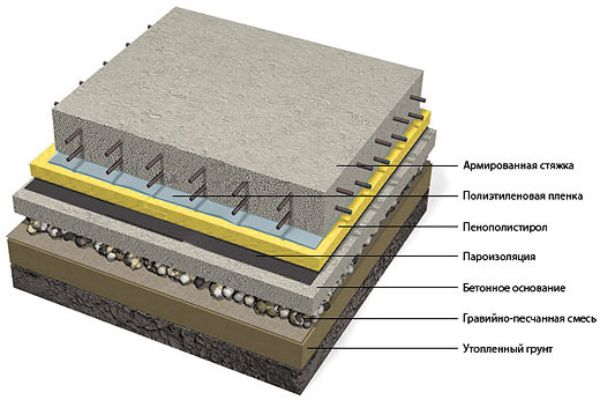

Concrete screed is one of the mostdurable building structures, but even it eventually becomes unusable. And this is not surprising, because the floor is subject to constant and very significant loads, leading to the destruction of the concrete monolith. Scheme of the device of a concrete floor on the ground.You can verify this if you need to replace the old floor covering. Such defects on the concrete surface as cracks, pits, potholes require immediate repair work. At the same time, they can be successfully carried out on your own, without resorting to calling specialists from construction companies.

Scheme of the device of a concrete floor on the ground.You can verify this if you need to replace the old floor covering. Such defects on the concrete surface as cracks, pits, potholes require immediate repair work. At the same time, they can be successfully carried out on your own, without resorting to calling specialists from construction companies.

What will be needed to strengthen the coating

Ideally, the old, dilapidated screed shouldremoved to the base, and a new layer of concrete must be laid in its place. But such a process is quite complex and takes a long time, so you can repair cracks and other defects in an easier way, using the following materials and tools: Scheme of leveling and compaction of concrete surface with a vibrator.

Scheme of leveling and compaction of concrete surface with a vibrator.

- perforator;

- Bulgarian with a disc on concrete or stone;

- hacksaw for metal;

- a hammer;

- marker;

- building syringe;

- reinforcing rod with a diameter of 1.2 cm;

- epoxy resin for concrete;

- quartz sand;

- primer and repair composition.

The use of this or that material and tool will depend on the type of defect in the screed. When everything is prepared, you can begin screeding the floors. Return to contents</a>

How to seal a crack on concrete

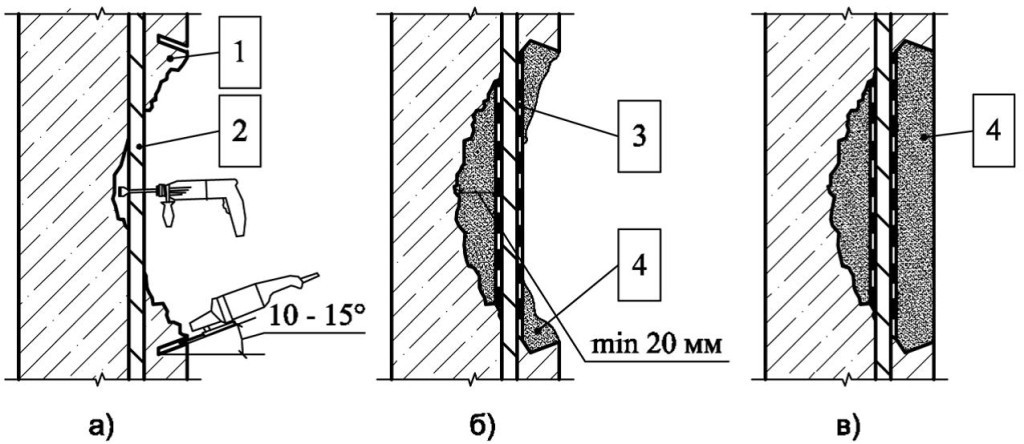

A crack is the most serious defectconcrete surface. This statement is due not only to the large size of the defect, but also to the fact that constant loads on the floor lead to rapid expansion of the pit. Therefore, sealing cracks can be considered not only necessary, but also an emergency measure. Scheme of repair of concrete defects with exposurereinforcement. Repair of a concrete surface should begin with preparing holes for brackets from a reinforcing bar. To do this, using a hammer drill with a drill bit with a slight slope of the working groove, drill holes with a diameter of 2 cm. The depth of each hole should correspond to the thickness of the floor screed layer. The holes should pass on both sides of the crack with a step of about 25 cm. Grooves about 2 cm deep are sawn between parallel holes. When drilling holes, it is necessary to take into account that their upper part should be expanded like a bowl. The diameter of such a bowl should be 4 cm, and the depth equal to half the depth of the hole. After the holes for repairing defects have been drilled, each of them must be cleaned. It is best to use a vacuum cleaner. The next stage of work is preparing brackets from a reinforcing bar. Here you will need a grinder or a hacksaw for metal. The rod is cut into pieces, the length of which should be equal to the sum of the following indicators:

Scheme of repair of concrete defects with exposurereinforcement. Repair of a concrete surface should begin with preparing holes for brackets from a reinforcing bar. To do this, using a hammer drill with a drill bit with a slight slope of the working groove, drill holes with a diameter of 2 cm. The depth of each hole should correspond to the thickness of the floor screed layer. The holes should pass on both sides of the crack with a step of about 25 cm. Grooves about 2 cm deep are sawn between parallel holes. When drilling holes, it is necessary to take into account that their upper part should be expanded like a bowl. The diameter of such a bowl should be 4 cm, and the depth equal to half the depth of the hole. After the holes for repairing defects have been drilled, each of them must be cleaned. It is best to use a vacuum cleaner. The next stage of work is preparing brackets from a reinforcing bar. Here you will need a grinder or a hacksaw for metal. The rod is cut into pieces, the length of which should be equal to the sum of the following indicators:

- distance between holes located opposite each other along the crack;

- the depth of the holes multiplied by 2.

Scheme of the macrostructure of concrete.For example, the holes are drilled at a distance of 3 cm from the cracks in the floor screed, so the distance between them will be 6 cm. The depth of the holes is 5 cm. This means that the length of the rod sections will be 16 cm: 6 cm + 5 cm × 2. But each bracket will be inserted into a sawn groove, the depth of which is 2 cm, so the length of the rod section must be reduced by 4 cm. Total: each bracket will be 12 cm long. Each rod must be bent at both ends at a right angle, making brackets for repairing concrete pavement. Then the resulting brackets must be treated with a degreasing solution. After this, epoxy resin for concrete screed should be diluted. In order to give the resin a texture close to concrete mortar, a little quartz sand is added to it. The resulting mixture is used to fill half of the crack and all the holes running along it, then the brackets from the rod are inserted into them. As soon as the solution has set and the staples are tight, the entire crack is filled. The final stage of the work is to fill the upper wide bowls with epoxy mortar. As a result, after the materials have hardened, reliable epoxy pins with metal reinforcement are obtained, firmly pulling together the edges of the crack. The surface of the concrete screed is leveled and carefully ground. Return to the table of contents</a>

Scheme of the macrostructure of concrete.For example, the holes are drilled at a distance of 3 cm from the cracks in the floor screed, so the distance between them will be 6 cm. The depth of the holes is 5 cm. This means that the length of the rod sections will be 16 cm: 6 cm + 5 cm × 2. But each bracket will be inserted into a sawn groove, the depth of which is 2 cm, so the length of the rod section must be reduced by 4 cm. Total: each bracket will be 12 cm long. Each rod must be bent at both ends at a right angle, making brackets for repairing concrete pavement. Then the resulting brackets must be treated with a degreasing solution. After this, epoxy resin for concrete screed should be diluted. In order to give the resin a texture close to concrete mortar, a little quartz sand is added to it. The resulting mixture is used to fill half of the crack and all the holes running along it, then the brackets from the rod are inserted into them. As soon as the solution has set and the staples are tight, the entire crack is filled. The final stage of the work is to fill the upper wide bowls with epoxy mortar. As a result, after the materials have hardened, reliable epoxy pins with metal reinforcement are obtained, firmly pulling together the edges of the crack. The surface of the concrete screed is leveled and carefully ground. Return to the table of contents</a>

How to eliminate the peeling of concrete

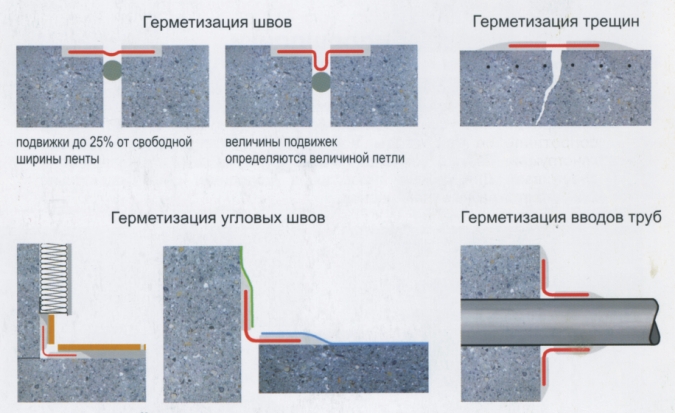

Sealing expansion joints of concrete floors.In order to detect peeling of the concrete monolith from the base, it is necessary to tap the screed with a hammer. The blows must be applied very carefully, because the main thing here is not the force, but the sound. Thus, a dull sound when struck will indicate the presence of peeling. If the screed has peeled off along the edges of the crack, then fountains of dust may knock out of it. First of all, the entire repair area must be marked with a marker or pencil. Then, in places where a dull sound is heard, and along the cracks, it is necessary to drill several holes with a diameter of about 2 cm with a hammer drill. The step size between the holes is 25 cm. To eliminate peeling of the floor, the same epoxy resin is used, only quartz sand is not used in this case, and the solution should be more liquid. Then it is necessary to prepare a construction syringe, with the help of which the "injections" of the screed will occur. The solution is poured into the syringe, and then into the drilled holes. When the resin does not go deep into the hole and it is filled, it should be considered that the peeling of the floor screed in this place is eliminated. In this case, several approaches to the holes may be required, since the solution will not immediately displace the air locks formed from under the concrete. This method of eliminating screed defects is very simple and quick: the next day after the work is carried out, you can lay the final floor covering. However, it should be taken into account that this type of repair is desirable to carry out in the case when peeling has affected no more than 1/3 of the entire floor area. If this is not the case, it is necessary to remove the concrete completely and make a new screed. Naturally, such repairs will be longer and more expensive, but also more reliable. Return to the table of contents</a>

Sealing expansion joints of concrete floors.In order to detect peeling of the concrete monolith from the base, it is necessary to tap the screed with a hammer. The blows must be applied very carefully, because the main thing here is not the force, but the sound. Thus, a dull sound when struck will indicate the presence of peeling. If the screed has peeled off along the edges of the crack, then fountains of dust may knock out of it. First of all, the entire repair area must be marked with a marker or pencil. Then, in places where a dull sound is heard, and along the cracks, it is necessary to drill several holes with a diameter of about 2 cm with a hammer drill. The step size between the holes is 25 cm. To eliminate peeling of the floor, the same epoxy resin is used, only quartz sand is not used in this case, and the solution should be more liquid. Then it is necessary to prepare a construction syringe, with the help of which the "injections" of the screed will occur. The solution is poured into the syringe, and then into the drilled holes. When the resin does not go deep into the hole and it is filled, it should be considered that the peeling of the floor screed in this place is eliminated. In this case, several approaches to the holes may be required, since the solution will not immediately displace the air locks formed from under the concrete. This method of eliminating screed defects is very simple and quick: the next day after the work is carried out, you can lay the final floor covering. However, it should be taken into account that this type of repair is desirable to carry out in the case when peeling has affected no more than 1/3 of the entire floor area. If this is not the case, it is necessary to remove the concrete completely and make a new screed. Naturally, such repairs will be longer and more expensive, but also more reliable. Return to the table of contents</a>

Methods for eliminating potholes

Scheme of repair of joints in concrete.Many property owners, when repairing their flooring, are surprised: how could potholes appear under parquet, linoleum or tiles? The answer is simple: when pouring the screed, air bubbles could remain in the concrete solution, which subsequently turned into potholes. In order to completely eliminate the cavity of the pothole, you will have to dig it out to the base. This process is usually done with a hammer drill or crowbar. Before work, you will need to cut out cuts along the perimeter of the pothole with a grinder with a disc for stone or concrete. The cuts should go along the entire depth of the floor screed. Thus, the cuts will have the form of a square or rectangle, in the center of which there will be a pothole. Then the repair is carried out as follows: all the concrete between the cuts is crumbled with a hammer drill or crowbar, then the pieces are removed manually, and the dust is collected with a vacuum cleaner. The entire thoroughly cleaned surface must be primed. To do this, use a special primer that matches the repair compound used to repair cracks and potholes. This can be a mixture such as Kema, Ivsil, and many others. Then the pothole is sealed with a repair compound. If the screed layer is too thick, the work is carried out in several approaches as the previous layer of repair compound dries. As a rule, such mixtures dry completely within 24-36 hours. If work on repairing cracks and other defects is carried out in an unheated room during the cold season, you will have to wait longer for drying. After the repair compound has completely polymerized, its surface must be carefully sanded. It is advisable to use a special grinding machine for this, but in extreme cases, hand tools will do. If, when replacing the final floor covering, it was discovered that the entire surface of the concrete was cracked, do not despair. You can repair screed defects yourself as skillfully as a professional. This will allow you to save money from your family budget.</ ul>

Scheme of repair of joints in concrete.Many property owners, when repairing their flooring, are surprised: how could potholes appear under parquet, linoleum or tiles? The answer is simple: when pouring the screed, air bubbles could remain in the concrete solution, which subsequently turned into potholes. In order to completely eliminate the cavity of the pothole, you will have to dig it out to the base. This process is usually done with a hammer drill or crowbar. Before work, you will need to cut out cuts along the perimeter of the pothole with a grinder with a disc for stone or concrete. The cuts should go along the entire depth of the floor screed. Thus, the cuts will have the form of a square or rectangle, in the center of which there will be a pothole. Then the repair is carried out as follows: all the concrete between the cuts is crumbled with a hammer drill or crowbar, then the pieces are removed manually, and the dust is collected with a vacuum cleaner. The entire thoroughly cleaned surface must be primed. To do this, use a special primer that matches the repair compound used to repair cracks and potholes. This can be a mixture such as Kema, Ivsil, and many others. Then the pothole is sealed with a repair compound. If the screed layer is too thick, the work is carried out in several approaches as the previous layer of repair compound dries. As a rule, such mixtures dry completely within 24-36 hours. If work on repairing cracks and other defects is carried out in an unheated room during the cold season, you will have to wait longer for drying. After the repair compound has completely polymerized, its surface must be carefully sanded. It is advisable to use a special grinding machine for this, but in extreme cases, hand tools will do. If, when replacing the final floor covering, it was discovered that the entire surface of the concrete was cracked, do not despair. You can repair screed defects yourself as skillfully as a professional. This will allow you to save money from your family budget.</ ul>