When performing major repairs inFor any purpose, the technical condition of the floors requires special attention. After a long operation, the coating can have a number of defects, which can be helped only by overhauling the floor screed.  After a long use of the concrete floor, it can get both minor damage and become covered with large cracks, which can only be corrected by completely replacing the screed.

After a long use of the concrete floor, it can get both minor damage and become covered with large cracks, which can only be corrected by completely replacing the screed.

Classification of defects

The easiest way is to completelyTo dismantle the existing covering to the very foundation and arrange a new screed. Such actions justify themselves in the event that there are no more ways to restore the old screed. Under normal conditions, this is unacceptable for a number of reasons:  Scheme for dismantling the damaged floor screed.

Scheme for dismantling the damaged floor screed.

It will be more correct to remove the top coatfloors, clean the surface of the existing screed and visually examine it, determining the number and size of defects. In the process of studying the entire area of the concrete surface, it is recommended to tap with a hammer gently for the presence of hidden voids in the thickness of the screed as a result of detachment. A dull sound will precisely indicate the place of such a defect. After all the damages and their number are determined, you can proceed with choosing the method of their elimination. There are several types of wear of old concrete floor coverings:  The peeling occurs because of temperature changes and the effects of moisture on the concrete.

The peeling occurs because of temperature changes and the effects of moisture on the concrete.

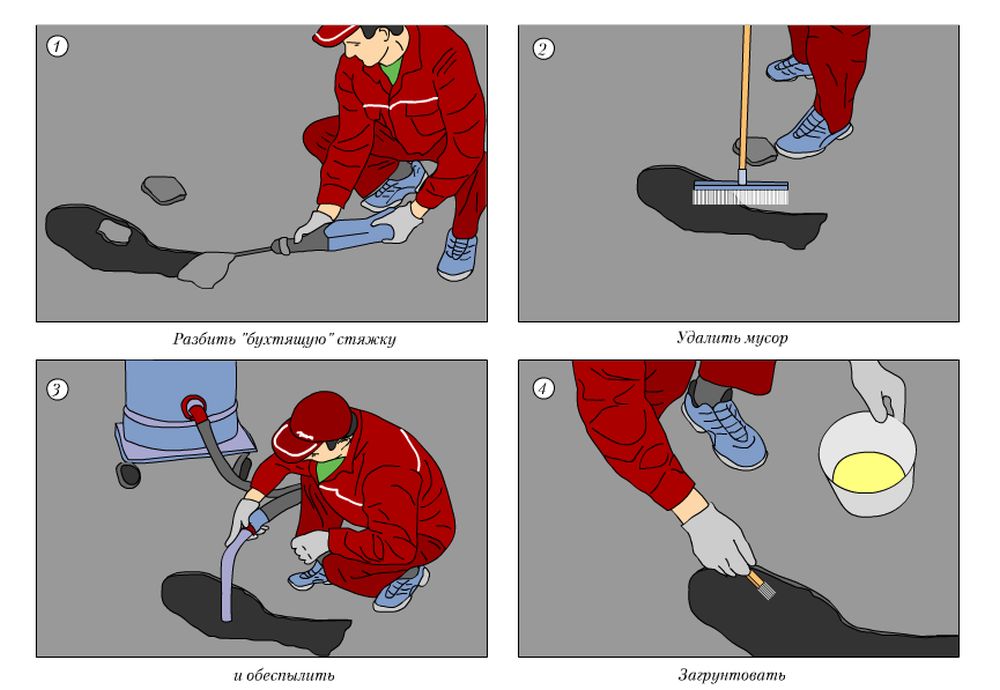

Back to contents</a> Elimination of minor damage Repair of smallcracks begin with the fact that they open them in width and depth. For this, an angle grinder is used with a cut circle around the stone and concrete. On both sides of the defect, the screed is cut through to a depth of 5 cm so that after removing the pieces of the old solution a groove of rectangular cross section 2-3 cm wide is obtained. It is cleaned and dust removed to assess the depth of the slot. If it turns out that the crack goes right to the bottom, then it will be necessary to perform the same work as in the case with through wide cracks.  Sequence repair screed. The sealing of the slot is made after applying primer to its walls, which will result in dedusting and hardening of the existing concrete layer. It may be necessary to primer several times, especially when it is noticeable that the surface absorbs the applied composition very much. To perform the last stage of repair, you need to prepare a special cement-sand mortar on the PVA glue. The recipe is as follows: the glue is mixed with water in a ratio of 1: 3, after which the solution itself is kneaded on this basis, the cement-sand ratio is 1: 3. Since the amount of work is not very large, it is preferable to do the batch in a plastic bucket (it is possible from under the paint) with an electric drill with a mixer nozzle. If the latter is missing, you can apply a piece of wire with a diameter of 6 mm, one end of which is bent upwards or in the form of a ring, and the second is fixed in the holder of the power tool. Using a trowel and a rule, the split crack is filled, and the surface is smoothed, removing the remnants of the solution. Subsequent work can be carried out not earlier than 20 days after the completion of repair, this applies to all types of repair of screed. The same method can be used to seal potholes and other mechanical damage in the surface of the concrete screed. Back to contents</a> Technology of sealing deep cracks

Sequence repair screed. The sealing of the slot is made after applying primer to its walls, which will result in dedusting and hardening of the existing concrete layer. It may be necessary to primer several times, especially when it is noticeable that the surface absorbs the applied composition very much. To perform the last stage of repair, you need to prepare a special cement-sand mortar on the PVA glue. The recipe is as follows: the glue is mixed with water in a ratio of 1: 3, after which the solution itself is kneaded on this basis, the cement-sand ratio is 1: 3. Since the amount of work is not very large, it is preferable to do the batch in a plastic bucket (it is possible from under the paint) with an electric drill with a mixer nozzle. If the latter is missing, you can apply a piece of wire with a diameter of 6 mm, one end of which is bent upwards or in the form of a ring, and the second is fixed in the holder of the power tool. Using a trowel and a rule, the split crack is filled, and the surface is smoothed, removing the remnants of the solution. Subsequent work can be carried out not earlier than 20 days after the completion of repair, this applies to all types of repair of screed. The same method can be used to seal potholes and other mechanical damage in the surface of the concrete screed. Back to contents</a> Technology of sealing deep cracks  The scheme of sealing of cracks in a concrete screed. Through wide cracks extend to the base with a perforator, broken pieces of old mortar and dust is removed. For this purpose, it is best to use compressed air to blow out all the excess garbage. If a pillow from rubble is found as the base, it will be necessary to compact it and fill it with liquid cement milk, if possible. Thus molochko should get under the divided edges of a coupler then it is necessary to give time for freezing. The base in the form of a reinforced concrete slab must be primed together with the edges of the resulting groove. Further repair of the screed is to fill the groove with a special compound. You can do this work by preparing the same solution as in the previous case, and smoothing it with the rule. But it should be understood that cracks of this size do not arise in the screed just and can appear again, so it is recommended to withstand the technology. In this case, do not save on self-preparation, it is better to buy a ready thixotropic mixture for floor repair in the retail network, at the same time to buy a special damper cord-sealer, this is used for the device of expansion joints. After stirring with the mixture, the entire divided niche is filled, with vertical markers made of fine steel wire along the entire crack. When the thixotropic mixture is seized, the markers can be pulled out to make them easier to exit, first they should be greased with a solidol. The next stage is the laying of the damper cord, under which a narrow groove with a depth of 5 cm is cut. After this operation, the groove is sealed with a plastic sealant based on silicone or polyurethane. As can be understood from the technology, the result of such repairs is the deformation seam device in place of a large floor crack. Whatever the reasons for its occurrence, new defects will not appear in this place. Stratification of concrete in the thickness of the screed can be eliminated by injection. Once all the places with this defect are found, it is necessary within these sections to drill the holes in the screed using a perforator and a drill with a diameter of 12 to 20 mm, the distance between the holes is 250 mm. Then they should be carefully filled in with a special formulation based on epoxy resins. If possible, it is better to use a syringe. Pour the produce until all the voids and pores are filled, the process is done intermittently, allowing the composition to soak into the concrete. Repair of floor screed with this method is not difficult, but requires attention and patience. After the epoxy glue has solidified, which will happen within 24 hours, it is possible to proceed with further work. The weakened surface layer of the screed can be made stronger by modern construction deep-penetrating compositions based on polyurethane. Such impregnations allow to raise the brand of screed solution from M50 to M300 to the required depth. After the floor has been treated with polyurethane compounds, the formation of cement dust ceases, and a protective film with a thickness of up to 200 μm appears on the surface of the concrete. Carrying out the restoration work of concrete flooring, it is possible to significantly save money that will inevitably be spent when dismantling and installing a new screed.

The scheme of sealing of cracks in a concrete screed. Through wide cracks extend to the base with a perforator, broken pieces of old mortar and dust is removed. For this purpose, it is best to use compressed air to blow out all the excess garbage. If a pillow from rubble is found as the base, it will be necessary to compact it and fill it with liquid cement milk, if possible. Thus molochko should get under the divided edges of a coupler then it is necessary to give time for freezing. The base in the form of a reinforced concrete slab must be primed together with the edges of the resulting groove. Further repair of the screed is to fill the groove with a special compound. You can do this work by preparing the same solution as in the previous case, and smoothing it with the rule. But it should be understood that cracks of this size do not arise in the screed just and can appear again, so it is recommended to withstand the technology. In this case, do not save on self-preparation, it is better to buy a ready thixotropic mixture for floor repair in the retail network, at the same time to buy a special damper cord-sealer, this is used for the device of expansion joints. After stirring with the mixture, the entire divided niche is filled, with vertical markers made of fine steel wire along the entire crack. When the thixotropic mixture is seized, the markers can be pulled out to make them easier to exit, first they should be greased with a solidol. The next stage is the laying of the damper cord, under which a narrow groove with a depth of 5 cm is cut. After this operation, the groove is sealed with a plastic sealant based on silicone or polyurethane. As can be understood from the technology, the result of such repairs is the deformation seam device in place of a large floor crack. Whatever the reasons for its occurrence, new defects will not appear in this place. Stratification of concrete in the thickness of the screed can be eliminated by injection. Once all the places with this defect are found, it is necessary within these sections to drill the holes in the screed using a perforator and a drill with a diameter of 12 to 20 mm, the distance between the holes is 250 mm. Then they should be carefully filled in with a special formulation based on epoxy resins. If possible, it is better to use a syringe. Pour the produce until all the voids and pores are filled, the process is done intermittently, allowing the composition to soak into the concrete. Repair of floor screed with this method is not difficult, but requires attention and patience. After the epoxy glue has solidified, which will happen within 24 hours, it is possible to proceed with further work. The weakened surface layer of the screed can be made stronger by modern construction deep-penetrating compositions based on polyurethane. Such impregnations allow to raise the brand of screed solution from M50 to M300 to the required depth. After the floor has been treated with polyurethane compounds, the formation of cement dust ceases, and a protective film with a thickness of up to 200 μm appears on the surface of the concrete. Carrying out the restoration work of concrete flooring, it is possible to significantly save money that will inevitably be spent when dismantling and installing a new screed.