One of the main tasks of apartment renovation isthis is to get a level floor. Whatever the external covering, it is impossible to solve this problem without carrying out . Only with a high-quality screed will the floors look perfect. Floor screed, like any covering, requiresrepairs that need to be done in a timely manner so that it does not need to be completely replaced. Do-it-yourself repair of the floor screed is not a very difficult task, but it will require some physical effort and will require material costs. These inconveniences should not stop the owner. Any coatings age over time and become covered with obvious and hidden defects, but it is much more profitable to make timely partial repairs than to completely replace the screed when its destruction intensifies.

Floor screed, like any covering, requiresrepairs that need to be done in a timely manner so that it does not need to be completely replaced. Do-it-yourself repair of the floor screed is not a very difficult task, but it will require some physical effort and will require material costs. These inconveniences should not stop the owner. Any coatings age over time and become covered with obvious and hidden defects, but it is much more profitable to make timely partial repairs than to completely replace the screed when its destruction intensifies.

What is the role of the coating?

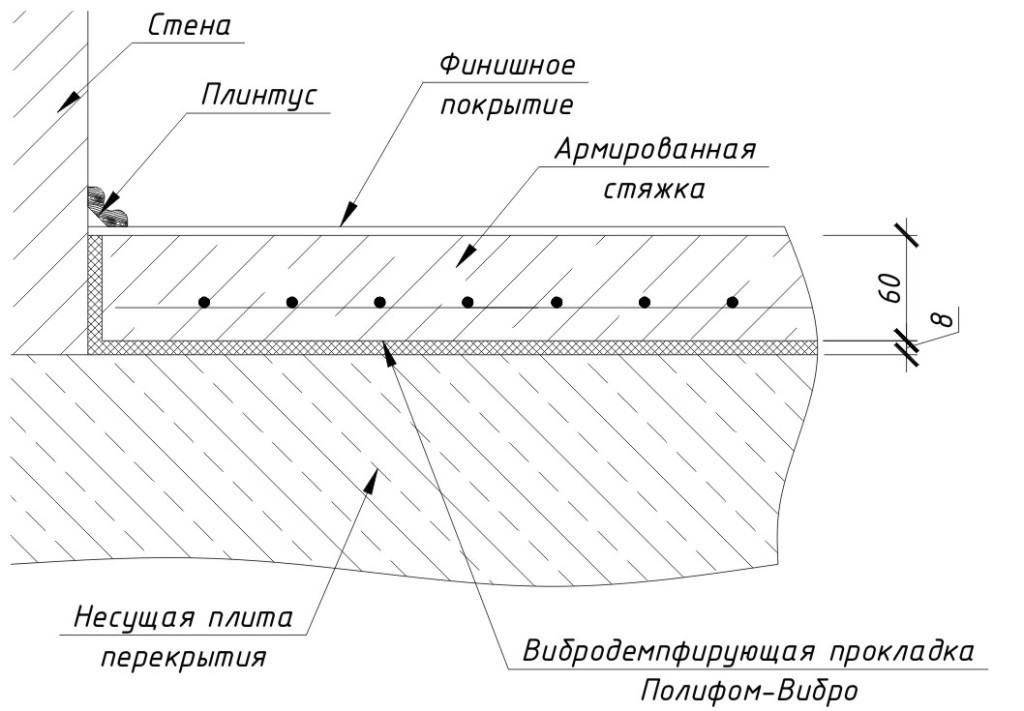

Scheme of the screed pouring process.In any room, between the final floor covering and the floor slabs, there is a floor screed. It is usually made of concrete mortar of varying thickness. In modern designs, a special mixture for self-leveling floors is used. The floor screed itself is hidden under the floor covering and therefore it may seem that it is not subject to destruction. However, in fact, the main task of the concrete coating is to take on the main mechanical load acting on the floor. It is a damper layer for the floor. Constant mechanical load, naturally, leads to gradual destruction of the floor screed material. An important role of the screed is that it levels the surface and thereby ensures the horizontality and evenness of the outer floor covering and increases its durability. In addition, the concrete coating is designed to hide various communications: electrical wiring, pipes, floor heating, etc. Finally, the screed is an additional layer providing thermal and sound insulation. The role that the coating plays in ensuring the quality and reliability of the floor is enormous, so it is so necessary to independently monitor its condition and ensure its functionality. Return to contents</a>

Scheme of the screed pouring process.In any room, between the final floor covering and the floor slabs, there is a floor screed. It is usually made of concrete mortar of varying thickness. In modern designs, a special mixture for self-leveling floors is used. The floor screed itself is hidden under the floor covering and therefore it may seem that it is not subject to destruction. However, in fact, the main task of the concrete coating is to take on the main mechanical load acting on the floor. It is a damper layer for the floor. Constant mechanical load, naturally, leads to gradual destruction of the floor screed material. An important role of the screed is that it levels the surface and thereby ensures the horizontality and evenness of the outer floor covering and increases its durability. In addition, the concrete coating is designed to hide various communications: electrical wiring, pipes, floor heating, etc. Finally, the screed is an additional layer providing thermal and sound insulation. The role that the coating plays in ensuring the quality and reliability of the floor is enormous, so it is so necessary to independently monitor its condition and ensure its functionality. Return to contents</a>

Types of damage to the floor screed

Floor screed diagram.Under the influence of various loads or due to poor manufacturing, the floor screed is subject to destruction. When removing the top floor covering, all the defects that have arisen become visible and can be assessed for the possibility of doing floor repairs yourself. The main types of screed damage include: the appearance of noticeable cracks or potholes, peeling of concrete from floor slabs in certain areas with the formation of air gaps, minor cracking, peeling or the formation of small cavities and holes on the surface of the screed. Cracks, and sometimes large gaps, are formed due to uneven or impact loads, as well as due to construction violations: lack of shrinkage joints, insufficient reinforcement or poor-quality concrete pouring. Such damage is very dangerous due to its tendency to increase in size and number of cracks. When removing the floor covering, these defects are visible to the naked eye. Potholes and large cavities appear in areas of local heavy loads (for example, vibration of household equipment) or in places where a void appeared in the concrete during its pouring. Concrete separation from the floor may occur due to uneven loads or poor surface preparation before pouring concrete. Such damage is not noticeable from the outside and can be determined by a dull sound when tapping with a hammer. Poor-quality concrete or violations of pouring modes are the cause of multiple surface damages, which manifest themselves in the form of peeling of the screed surface, heavy dusting or small web-like cracks. All the types of damage considered can be repaired by yourself in certain areas. The only condition for the expediency of its implementation is the disadvantage of damage to more than 35% of the screed surface. In this case, it is recommended to completely replace the screed. Return to the table of contents</a>

Floor screed diagram.Under the influence of various loads or due to poor manufacturing, the floor screed is subject to destruction. When removing the top floor covering, all the defects that have arisen become visible and can be assessed for the possibility of doing floor repairs yourself. The main types of screed damage include: the appearance of noticeable cracks or potholes, peeling of concrete from floor slabs in certain areas with the formation of air gaps, minor cracking, peeling or the formation of small cavities and holes on the surface of the screed. Cracks, and sometimes large gaps, are formed due to uneven or impact loads, as well as due to construction violations: lack of shrinkage joints, insufficient reinforcement or poor-quality concrete pouring. Such damage is very dangerous due to its tendency to increase in size and number of cracks. When removing the floor covering, these defects are visible to the naked eye. Potholes and large cavities appear in areas of local heavy loads (for example, vibration of household equipment) or in places where a void appeared in the concrete during its pouring. Concrete separation from the floor may occur due to uneven loads or poor surface preparation before pouring concrete. Such damage is not noticeable from the outside and can be determined by a dull sound when tapping with a hammer. Poor-quality concrete or violations of pouring modes are the cause of multiple surface damages, which manifest themselves in the form of peeling of the screed surface, heavy dusting or small web-like cracks. All the types of damage considered can be repaired by yourself in certain areas. The only condition for the expediency of its implementation is the disadvantage of damage to more than 35% of the screed surface. In this case, it is recommended to completely replace the screed. Return to the table of contents</a>

Minor cracks and repair

Small cracks in the screed can be sealedwith a regular concrete solution. Small visible cracks are repaired in the following order. Using a chisel, the crack is widened and deepened by 10-15 mm. The crack and the area around it are thoroughly cleaned of dust with a vacuum cleaner. A solution of epoxy primer in a solvent (proportion 1:10) is applied to the surface of the crack and dried. Such surface treatment improves the adhesion of the filling solution to the surface of the crack. After that, a solution is poured into the crack or gap, which is a special mixture for screeding a self-leveling floor. The dried area is sanded. Small cracks in the screed can usually be repaired using cheaper conventional primer and plaster mixtures on a cement base. However, such repairs are likely to be short-lived, since the cause of the previous damage remains. The use of mixtures on an epoxy or other adhesive synthetic base significantly strengthens the dangerous area and allows you to neutralize the source of cracks. Return to the table of contents</a>

Small cracks in the screed can be sealedwith a regular concrete solution. Small visible cracks are repaired in the following order. Using a chisel, the crack is widened and deepened by 10-15 mm. The crack and the area around it are thoroughly cleaned of dust with a vacuum cleaner. A solution of epoxy primer in a solvent (proportion 1:10) is applied to the surface of the crack and dried. Such surface treatment improves the adhesion of the filling solution to the surface of the crack. After that, a solution is poured into the crack or gap, which is a special mixture for screeding a self-leveling floor. The dried area is sanded. Small cracks in the screed can usually be repaired using cheaper conventional primer and plaster mixtures on a cement base. However, such repairs are likely to be short-lived, since the cause of the previous damage remains. The use of mixtures on an epoxy or other adhesive synthetic base significantly strengthens the dangerous area and allows you to neutralize the source of cracks. Return to the table of contents</a>

Repair of large cracks

Step-by-step repair of large cracks in the screed.Large and deep cracks in the floor screed are also subject to repair. To do this, the cracks are widened and deepened to the floor slab or to a depth of at least 50 mm using a grinder. Grooves are made in the cracks on the side surfaces. The widened crack is thoroughly cleaned of dirt and dust. Grooves 15-20 cm long and 20 mm deep are punched along the crack perpendicular to it. The distance between the grooves is set at 20-30 mm. The crack and the adjacent area are thoroughly cleaned with a vacuum cleaner. Just as in the case of small cracks, the entire area of the large crack is treated with a primer solution. Large cracks are sealed with a mixture for screeding a self-leveling floor or a special epoxy solution for concrete (for example, brand Rizopox-3500) filled with quartz sand. The crack is filled in two stages. First, the crack is filled to the depth of the beginning of the grooves. Metal brackets are installed vertically in the transverse grooves. The final pouring of the solution into the crack is carried out after the first layer has dried and the metal brackets have been fixed in it. When repairing particularly deep cracks, the solution can be poured in three stages. After the area of the screed repair has dried, all irregularities are eliminated by cleaning and grinding. This DIY method allows you to reinforce the dangerous area with metal elements, which eliminates the risk of repeated cracks or crevices. Return to contents</a>

Step-by-step repair of large cracks in the screed.Large and deep cracks in the floor screed are also subject to repair. To do this, the cracks are widened and deepened to the floor slab or to a depth of at least 50 mm using a grinder. Grooves are made in the cracks on the side surfaces. The widened crack is thoroughly cleaned of dirt and dust. Grooves 15-20 cm long and 20 mm deep are punched along the crack perpendicular to it. The distance between the grooves is set at 20-30 mm. The crack and the adjacent area are thoroughly cleaned with a vacuum cleaner. Just as in the case of small cracks, the entire area of the large crack is treated with a primer solution. Large cracks are sealed with a mixture for screeding a self-leveling floor or a special epoxy solution for concrete (for example, brand Rizopox-3500) filled with quartz sand. The crack is filled in two stages. First, the crack is filled to the depth of the beginning of the grooves. Metal brackets are installed vertically in the transverse grooves. The final pouring of the solution into the crack is carried out after the first layer has dried and the metal brackets have been fixed in it. When repairing particularly deep cracks, the solution can be poured in three stages. After the area of the screed repair has dried, all irregularities are eliminated by cleaning and grinding. This DIY method allows you to reinforce the dangerous area with metal elements, which eliminates the risk of repeated cracks or crevices. Return to contents</a>

Repair of potholes and surface shells

A pothole in a screed can be repaired usingspecial resin-based sealant. Potholes on the surface of the coating can occupy a significant area. In this case, do-it-yourself screed repair is carried out in several stages. First, using a grinder, cuts are made along the perimeter of the pothole with a depth of 2 cm greater than the depth of the pothole. If the pothole is deep, cuts are made to the base. Then, using a hammer drill, the concrete of the screed is removed inside the marked perimeter to the depth of the cut. The resulting depression is thoroughly cleaned of concrete residues and dust using a vacuum cleaner. At the next stage, the bottom and walls of the depression are covered with a primer. After it hardens, the repair mortar is poured in several layers. The thickness of each layer is usually selected within 20 mm. Each layer is poured after the previous one has hardened. For large repair areas, it is advisable to reinforce the repaired area with metal rods, mesh or synthetic threads. After the top layer of the solution has completely hardened, the entire repair area is cleaned and sanded so that its surface is strictly flush with the surface of the floor screed. Return to contents</a>

A pothole in a screed can be repaired usingspecial resin-based sealant. Potholes on the surface of the coating can occupy a significant area. In this case, do-it-yourself screed repair is carried out in several stages. First, using a grinder, cuts are made along the perimeter of the pothole with a depth of 2 cm greater than the depth of the pothole. If the pothole is deep, cuts are made to the base. Then, using a hammer drill, the concrete of the screed is removed inside the marked perimeter to the depth of the cut. The resulting depression is thoroughly cleaned of concrete residues and dust using a vacuum cleaner. At the next stage, the bottom and walls of the depression are covered with a primer. After it hardens, the repair mortar is poured in several layers. The thickness of each layer is usually selected within 20 mm. Each layer is poured after the previous one has hardened. For large repair areas, it is advisable to reinforce the repaired area with metal rods, mesh or synthetic threads. After the top layer of the solution has completely hardened, the entire repair area is cleaned and sanded so that its surface is strictly flush with the surface of the floor screed. Return to contents</a>

Eliminating the peeling of concrete screeds

By tapping with a hammer it is necessaryspecify the area of delamination of the concrete floor screed from the floor slabs. The boundaries of the zone are marked with chalk or a colored marker. Inside the marked zone, holes with a diameter of about 20 mm are punched through the concrete screed to the surface of the floor. The distance between the holes is 25-30 cm. The number of holes is determined by the area of delamination. The principle of repairing such damage is based on the fact that an air gap is formed in the area of concrete delamination from the base and it must be filled with mass. To do this, the filling solution is diluted to a liquid consistency and poured into a construction syringe. Through the punched holes, the solution is fed to the delamination area and must completely fill it, ensuring adhesion to the concrete of the screed and the floor. After the air gap has been completely eliminated, the punched holes are filled in the same way as repairing cracks. The areas of the holes are cleaned and polished. If, by tapping the screed, it was possible to establish that the total area of concrete delamination exceeds a third of the entire area of the screed, repair is impractical. The coupler should be completely dismantled and replaced with a new one. Return to Contents</a>

Repair of surface defects

One of the unpleasant (though not very dangerous)defects of the floor screed surface is constant dusting, which is caused by shallow destruction of the surface. To eliminate such a defect, it is necessary to thoroughly clean the surface from dust and treat it with a special fixing compound. Building mixtures such as "Elakor" and "Ashfor" have proven themselves to be effective. Before applying these dust-removing compounds, it is recommended to clean the entire surface of the screed to ensure the necessary adhesion of the compound and concrete. The solution can be applied with a paint roller. In addition to the dust-removing effect, these substances increase the wear resistance of the floor screed coating. Return to contents</a>

Leveling of screed areas

When dismantling the floor covering,unevenness of the floor screed surface may be detected. They may be caused by both poor-quality screed production and surface damage. It is advisable to level the surface in local areas of the screed by applying a self-leveling mixture for self-leveling floors. To do this, you should first thoroughly clean the concrete surface and treat it twice with a soda solution. The mixture is applied with a roller and leveled. The tool and equipment needed to repair the floor screed with your own hands:

- perforator;

- Bulgarian;

- chisel;

- sledgehammer;

- paint roller;

- paint brush;

- Master OK;

- putty knife;

- syringe building;

- drill;

- sandpaper.

The quality and durability of floor coverings largely depends on the condition of the screed. Timely and high-quality repair of the screed with your own hands will allow you not to worry about the floor in the apartment.