Laminate is becoming one of the most popular materials today.popular floor coverings, and among the materials that have appeared in the last 20-25 years, it is the undisputed leader. A wide choice of patterns, strength and durability of the material, simple and understandable, allowing even a non-specialist to perform the work - these are the main reasons for such success. Laminate construction.But in order for the laminate floor to please its owners with its durability and beauty for many years, it is necessary to follow the golden rules of laying laminate when working. Failure to follow these simple but extremely important rules will, at best, entail a significant reduction in the service life of the floor, and at worst - the need to redo the work done.

Laminate construction.But in order for the laminate floor to please its owners with its durability and beauty for many years, it is necessary to follow the golden rules of laying laminate when working. Failure to follow these simple but extremely important rules will, at best, entail a significant reduction in the service life of the floor, and at worst - the need to redo the work done.

Features of the choice and preparation of material

Guaranteed service life of lower classeslaminate - from 5 to 7 years. For higher classes, this period increases to 10-15 years. The class of the material is determined not so much by the quality of the supporting wooden base used to make the lamellas, but by additives that extend the service life, the quality of the connecting locks, the number of layers of protective film coating, as well as the thickness of the lamellas, wear resistance and quality of the decor. To understand the variety of models and not make a mistake with the choice, you need to remember that for residential premises, manufacturers recommend using material of class 21, 22 or 23, and for office and industrial premises, they use laminate from class 31 to 34. Types of laminate.Despite such recommendations, if finances allow, it is better to use at least class 31 material for laying laminate in an apartment, since lower classes are not particularly resistant to abrasion and especially to excess moisture. If the budget forces you to save, then in this case, class 23 laminate can be used for the floor in bedrooms, living rooms and halls, and for rooms with high humidity and high traffic intensity - hallway, corridor, kitchen and toilet, use class 31 or even 32. Regular laminate cannot be used for bathrooms, shower cabins and saunas. When buying, keep in mind that experts do not recommend using lamellas less than 8 mm thick for laying laminate. When calculating the required amount of material, you need to take into account not only the floor area, but also the method of laying the laminate. With regular laying, you need to add a reserve of 5-7% to the required amount, and with diagonal laying, this reserve should be increased to 10-12%. It is very important to follow the acclimatization rule for the material when installing a laminate floor, since the temperature and humidity conditions in the storage and installation areas may differ significantly. This rule states that the purchased material must be brought into the room where the installation will take place and left without unpacking for at least 48 hours for acclimatization, ensuring, if possible, optimal conditions: a temperature of 18-20°C and a relative humidity of 70-75%. Return to contents</a>

Types of laminate.Despite such recommendations, if finances allow, it is better to use at least class 31 material for laying laminate in an apartment, since lower classes are not particularly resistant to abrasion and especially to excess moisture. If the budget forces you to save, then in this case, class 23 laminate can be used for the floor in bedrooms, living rooms and halls, and for rooms with high humidity and high traffic intensity - hallway, corridor, kitchen and toilet, use class 31 or even 32. Regular laminate cannot be used for bathrooms, shower cabins and saunas. When buying, keep in mind that experts do not recommend using lamellas less than 8 mm thick for laying laminate. When calculating the required amount of material, you need to take into account not only the floor area, but also the method of laying the laminate. With regular laying, you need to add a reserve of 5-7% to the required amount, and with diagonal laying, this reserve should be increased to 10-12%. It is very important to follow the acclimatization rule for the material when installing a laminate floor, since the temperature and humidity conditions in the storage and installation areas may differ significantly. This rule states that the purchased material must be brought into the room where the installation will take place and left without unpacking for at least 48 hours for acclimatization, ensuring, if possible, optimal conditions: a temperature of 18-20°C and a relative humidity of 70-75%. Return to contents</a>

Features of surface preparation

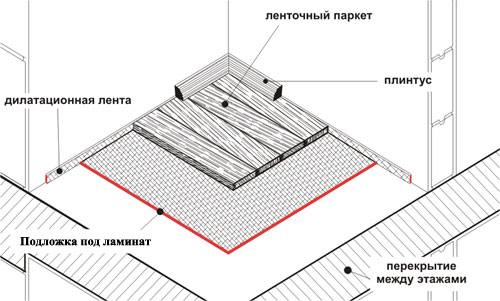

Scheme of laying laminate on screed.varies depending on its material, but the general rule remains the same - the base must be perfectly flat. A height difference of no more than 2-3 mm per 1 m of floor surface is allowed. Laying on an uneven base will cause the floor to swell or, at a minimum, break the locking joints in the first 2-3 months of operation. If the floor is to be laid on a concrete base, it must first be leveled using a sand-cement screed. When laying on a wooden base, it is imperative to level the surface with plywood sheets, and with significant (more than 3 cm per m) surface differences - with OSB boards. Following the rules for laying laminate: the greater the differences in the surface of the subfloor, the greater the thickness of the boards should be. Since the basis of the laminate is a material similar in its physiological characteristics to fiberboard, it is better to perform additional waterproofing on the screed to extend the service life of the laminate floor. For its installation, a polyethylene film of at least 0.2 mm thickness is usually used, which is spread directly on the base. The base must first be swept, or even better - vacuumed. The strips of polyethylene film must be laid perpendicular to the planned direction of laying, overlapping the strips by 15-20 cm, and also around the entire perimeter of the room, overlapping the walls by 5-7 cm. For better fixation of the strips, you can use double-sided tape. Return to the table of contents</a>

Scheme of laying laminate on screed.varies depending on its material, but the general rule remains the same - the base must be perfectly flat. A height difference of no more than 2-3 mm per 1 m of floor surface is allowed. Laying on an uneven base will cause the floor to swell or, at a minimum, break the locking joints in the first 2-3 months of operation. If the floor is to be laid on a concrete base, it must first be leveled using a sand-cement screed. When laying on a wooden base, it is imperative to level the surface with plywood sheets, and with significant (more than 3 cm per m) surface differences - with OSB boards. Following the rules for laying laminate: the greater the differences in the surface of the subfloor, the greater the thickness of the boards should be. Since the basis of the laminate is a material similar in its physiological characteristics to fiberboard, it is better to perform additional waterproofing on the screed to extend the service life of the laminate floor. For its installation, a polyethylene film of at least 0.2 mm thickness is usually used, which is spread directly on the base. The base must first be swept, or even better - vacuumed. The strips of polyethylene film must be laid perpendicular to the planned direction of laying, overlapping the strips by 15-20 cm, and also around the entire perimeter of the room, overlapping the walls by 5-7 cm. For better fixation of the strips, you can use double-sided tape. Return to the table of contents</a>

The use of a substrate under the laminate

Scheme of laying the underlay for laminate.Most often, when doing the work yourself, people neglect laying the underlayment under the laminate. This is partly due to the desire of the owners to save additionally on the cost of materials, partly due to a lack of understanding of the importance of such a technological process. The underlayment plays an important role as a shock absorber, dampening floor vibrations when walking, and also compensates for the expansion and contraction of the laminate when the temperature and humidity conditions in the room change. It is very important to use special underlayments under the laminate, and not rolled insulation, since these two publications are very similar in appearance. But rolled insulation, especially if it is made on the basis of foamed polystyrene, practically does not allow water vapor to pass through, so all the moisture coming out of the room through the floor will accumulate on its surface and be absorbed into the lamellas. Laminate laid on such a underlayment will last a maximum of 3-4 years. Unlike polyethylene film, the underlayment under the laminate should not be laid overlapping, but end to end. To prevent the underlay tapes from shifting, they are fastened together with adhesive tape. There is no point in putting it on the walls, since the underlay should be located directly under the laminate. And only after laying the underlay can you begin laying the laminate itself. Return to contents</a>

Scheme of laying the underlay for laminate.Most often, when doing the work yourself, people neglect laying the underlayment under the laminate. This is partly due to the desire of the owners to save additionally on the cost of materials, partly due to a lack of understanding of the importance of such a technological process. The underlayment plays an important role as a shock absorber, dampening floor vibrations when walking, and also compensates for the expansion and contraction of the laminate when the temperature and humidity conditions in the room change. It is very important to use special underlayments under the laminate, and not rolled insulation, since these two publications are very similar in appearance. But rolled insulation, especially if it is made on the basis of foamed polystyrene, practically does not allow water vapor to pass through, so all the moisture coming out of the room through the floor will accumulate on its surface and be absorbed into the lamellas. Laminate laid on such a underlayment will last a maximum of 3-4 years. Unlike polyethylene film, the underlayment under the laminate should not be laid overlapping, but end to end. To prevent the underlay tapes from shifting, they are fastened together with adhesive tape. There is no point in putting it on the walls, since the underlay should be located directly under the laminate. And only after laying the underlay can you begin laying the laminate itself. Return to contents</a>

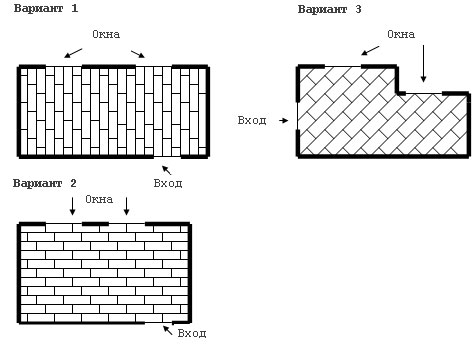

Methods of laying a laminate

There are several, differingthe direction of laying the lamellas and the method of connecting the floors in adjacent rooms. The direction can be parallel to the walls, the direction of the sun's rays, or diagonal. Floors in adjacent rooms can be laid using thresholds or without thresholds. There are no specific recommendations when choosing a method of laying, so you need to be guided by common sense. So, in large rooms, it is better to lay the laminate along the sunlight falling from the windows, in long rectangular rooms - for example, a corridor - along the direction of the walls. In corner rooms of a square or any rooms of complex architectural shape, diagonal laying is preferable. Threshold-free laying can be done in small rooms, the total area of which does not exceed 60-65 m². For rooms with a larger total area, it is preferable to lay the laminate using thresholds, since with large arrays and movements, the floor area will be larger, and this is fraught with deformation of the surface of the laid floor. Laminate flooring installation options.But regardless of the chosen method of installation, the set of tools for laying laminate and the basic rules of installation remain common. For high-quality installation, you will need the following devices and tools:

Laminate flooring installation options.But regardless of the chosen method of installation, the set of tools for laying laminate and the basic rules of installation remain common. For high-quality installation, you will need the following devices and tools:

- a hammer;

- nylon or kapron cord;

- roulette:

- pencil;

- electric jigsaw or hacksaw with small teeth;

- block for padding;

- clamp (for fitting and laying the last row).

Laminate is installed using a floating method, that iswithout fixing to the subfloor. This installation technology necessarily requires leaving thermal gaps at the walls. Practitioners have an unwritten rule: for every 2 linear meters of flooring, lay 1.5 mm of thermal gaps at each wall, but the minimum size of such gaps cannot be less than 7 mm. Failure to comply with this rule at least at one of the walls will cause deformation of the floor due to temperature shifts. It is very important to comply with this rule not only at the walls, but also at doorways and utility lines, and the presence of heavy furniture built into the wall in the room, due to which the floor can only move in one direction, requires the installation of a double thermal gap near the opposite wall. It is very important to comply with the rule of bandaging adjacent rows when laying. It is impossible to allow the locking joints of the lamellas laid in adjacent rows to be at the same level, it is necessary that their displacement relative to each other is at least 25 cm, and ideally - 40-50 cm. Only by following all these rules and, in addition, performing high-quality installation, you can be sure that the installed floor will serve you faithfully for many years. Good luck!