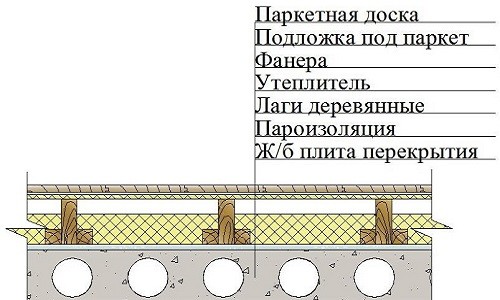

When creating an interior, special attention should be paidattention to the floor not only because when entering a room, people often glance at it initially, but also because the floor surface is subject to significant loads. Despite the fact that in the modern market you can find a variety of floor design options, wood does not lose its position. Parquet is often chosen as a classic finishing coating today. Over time, it can lose its former gloss and impeccability, but this does not mean that there will be a need to change the coating - it is permissible to sand it yourself. Section of a floor with parquet boards.

Section of a floor with parquet boards.

Preparing for a cycle

Floor sanding will help to achieve a renewed lookcoating from which scratches and chips will be removed. Carrying out the renovation involves removing the top decorative coating, which acts as a protective one. The base becomes smooth due to grinding and applying a new layer of varnish or wax. Do-it-yourself sanding can be done using a special tool called a scraper, or you can use special equipment instead. The first method is not very suitable for a non-professional, since it requires a significant amount of physical effort, in addition, this type of work will take a lot of time. After their completion, it is not always possible to achieve the desired result, since the surface of the wooden floor can simply be damaged. If you decide to sand without having the appropriate skills, then in order to get a good result, you should use the rental service of special equipment. Tools for parquet renovation.Its use will guarantee the work will be completed in a short time and with the least physical effort. To perform floor sanding, you should prepare materials and tools:

Tools for parquet renovation.Its use will guarantee the work will be completed in a short time and with the least physical effort. To perform floor sanding, you should prepare materials and tools:

- grinding machine;

- a set of keys for mounting abrasive on the drum;

- scissors;

- putty knife;

- a vacuum cleaner;

- putty on wood;

- varnish;

- respirator;

- roller;

- tray.

Parquet sanding scheme to remove oldvarnish. Preparing the room will involve clearing the entire space of furniture. The floor should be cleaned of debris using a vacuum cleaner. Protruding nails and other elements, if any, should be removed from the boards. Skirting boards should be dismantled. If there were any replacements on the floor during the analysis of its condition, the planks that came off should be glued back on, while the damaged ones should be replaced in advance. You can also remove the protective coating layer from the floor using a sponge and white spirit. Before starting work, you should determine whether there are communications systems under the floor. If any were found, the boards that provide access to the wires or piping system should be reinforced using brass screws. Return to Contents</a>

Parquet sanding scheme to remove oldvarnish. Preparing the room will involve clearing the entire space of furniture. The floor should be cleaned of debris using a vacuum cleaner. Protruding nails and other elements, if any, should be removed from the boards. Skirting boards should be dismantled. If there were any replacements on the floor during the analysis of its condition, the planks that came off should be glued back on, while the damaged ones should be replaced in advance. You can also remove the protective coating layer from the floor using a sponge and white spirit. Before starting work, you should determine whether there are communications systems under the floor. If any were found, the boards that provide access to the wires or piping system should be reinforced using brass screws. Return to Contents</a>

Conducting a rough grinding

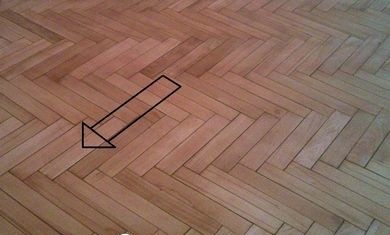

Scheme of parquet grinding to remove cracks andchips. Before starting to sand the floor with your own hands, it is important to determine how suitable the surface is for this type of repair, this will allow you to choose the right tactics. If the parquet has unevenness and has been used for a long time, then there is no point in leveling the bottom edge, since if you remove all the bulges, the planks will lose thickness, which will reduce their service life. In such circumstances, it is preferable to use a drum unit, the operating principle of which does not allow removing excess thickness, the machine works, bending around the unevenness. If sanding is carried out on new parquet, it is recommended to work with a flat grinding unit, which will help to arrange an initially smooth coating that will be easy to repair in the future. At the stage of rough sanding, the surface is leveled and the old varnish is removed. The process is carried out using a specialized machine that can remove the top thin layer of the coating. You do not need to try to do the work as quickly as possible. Despite the fact that modern technology does not give much dust, you still need to work in a respirator.

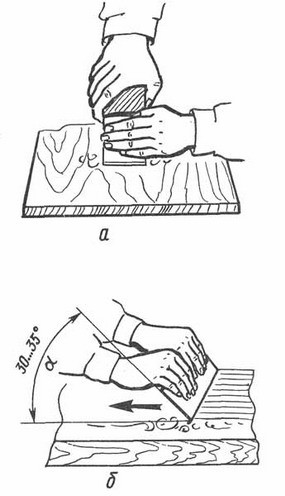

Scheme of parquet grinding to remove cracks andchips. Before starting to sand the floor with your own hands, it is important to determine how suitable the surface is for this type of repair, this will allow you to choose the right tactics. If the parquet has unevenness and has been used for a long time, then there is no point in leveling the bottom edge, since if you remove all the bulges, the planks will lose thickness, which will reduce their service life. In such circumstances, it is preferable to use a drum unit, the operating principle of which does not allow removing excess thickness, the machine works, bending around the unevenness. If sanding is carried out on new parquet, it is recommended to work with a flat grinding unit, which will help to arrange an initially smooth coating that will be easy to repair in the future. At the stage of rough sanding, the surface is leveled and the old varnish is removed. The process is carried out using a specialized machine that can remove the top thin layer of the coating. You do not need to try to do the work as quickly as possible. Despite the fact that modern technology does not give much dust, you still need to work in a respirator. Surface sanding:a — with a regular scraper; b — with a wide scraper. At the initial stage, sanding is carried out with coarse sandpaper loaded into the drum. Work should be started from the corner of the room. It is necessary to choose a diagonal direction, while it is necessary to start each subsequent track with some overlap on the previous one. At the first stage, it will be necessary to change the paper several times, as it will begin to tear and become clogged with sawdust. Sanding also involves periodic cleaning of the dust bag. After you have managed to sand the floor with your own hands, you can proceed to removing the next layer, while the direction must be changed, placing the tracks at a right angle to the previous layer. Each subsequent layer must be removed with paper of a finer grain. During the final sanding, you need to move parallel to the floorboards. After the work is completed and before starting to treat the surface with varnish, the floor should be thoroughly cleaned, this is the only way to ensure that the composition lies well on the base. It is better to avoid sweeping the floor for the next 24 hours to avoid excessive dust in the air. Before finally varnishing the surface, it must be treated with white spirit.

Surface sanding:a — with a regular scraper; b — with a wide scraper. At the initial stage, sanding is carried out with coarse sandpaper loaded into the drum. Work should be started from the corner of the room. It is necessary to choose a diagonal direction, while it is necessary to start each subsequent track with some overlap on the previous one. At the first stage, it will be necessary to change the paper several times, as it will begin to tear and become clogged with sawdust. Sanding also involves periodic cleaning of the dust bag. After you have managed to sand the floor with your own hands, you can proceed to removing the next layer, while the direction must be changed, placing the tracks at a right angle to the previous layer. Each subsequent layer must be removed with paper of a finer grain. During the final sanding, you need to move parallel to the floorboards. After the work is completed and before starting to treat the surface with varnish, the floor should be thoroughly cleaned, this is the only way to ensure that the composition lies well on the base. It is better to avoid sweeping the floor for the next 24 hours to avoid excessive dust in the air. Before finally varnishing the surface, it must be treated with white spirit. Manual cycle operation diagram.Some DIYers sometimes resort to using a grinder. This tool can be used only if you have certain professional skills in using this abrasive installation. You should be careful, and it is better to prefer sanding devices that ensure the safety of the work. It is convenient to use such installations, as they are easy to use and have a slight weight. In the area of the corners of the room, it is necessary to use corner sanding. It is impractical to purchase such specific equipment if you do not plan to do sanding professionally, as it is very expensive. Return to the table of contents</a>

Manual cycle operation diagram.Some DIYers sometimes resort to using a grinder. This tool can be used only if you have certain professional skills in using this abrasive installation. You should be careful, and it is better to prefer sanding devices that ensure the safety of the work. It is convenient to use such installations, as they are easy to use and have a slight weight. In the area of the corners of the room, it is necessary to use corner sanding. It is impractical to purchase such specific equipment if you do not plan to do sanding professionally, as it is very expensive. Return to the table of contents</a>

Putty filling and finishing

The next step is to putty the floor,which will get rid of cracks. The mixture used should contain sawdust. The final sanding is carried out using a three-disc flat sanding machine. You need to move along the wood grain. After that, you can start tinting the surface, for this you can use varnish, the application of the composition should be done in several stages. This completes the sanding process.