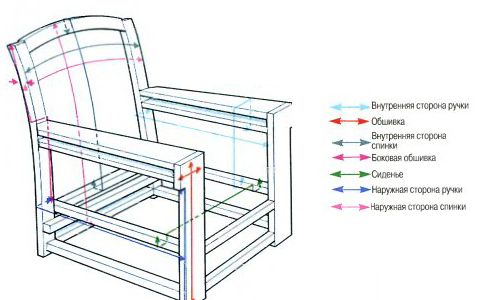

Every home craftsman knows that furniture can only be of high quality if it is made with your own hands. There are no trifles here, so it will not be so easy, but the result will please. Scheme of the chair structure.

Scheme of the chair structure.

Preparatory activities

Tools and materials:

- Laminated chipboard 20 mm;

- electric jigsaw;

- roulette;

- pencil;

- bar 50 * 40 mm;

- brush flat;

- antiseptic;

- sandpaper.

Chipboards are the optimal material for most types of furniture. They have a number of interesting features:

Tools for making a chair.A chipboard chair can be used as a chair and a bed, and the chair will be of medium height, and the bed is hard enough to provide quality rest. This approach will not force you to do something very complicated, but arbitrary modifications are possible if desired. At the very beginning, you need to organize the sawing of the chipboard for the future folding chair:

Tools for making a chair.A chipboard chair can be used as a chair and a bed, and the chair will be of medium height, and the bed is hard enough to provide quality rest. This approach will not force you to do something very complicated, but arbitrary modifications are possible if desired. At the very beginning, you need to organize the sawing of the chipboard for the future folding chair:

- Chipboard 90*70 cm - 3 segments;

- 23 cm bar - 4 cuts;

- 65 cm bar - 2 cuts;

- 70 cm bar - 6 cuts;

- 90 cm bar - 6 cuts;

- 60 cm bar - 6 cuts;

- 95 cm bar - 1 cut;

- 50 cm bar - 2 cuts;

- 30 cm bar - 3 cuts.

It is with this material that all work will be carried outfurther activities. Some will still have to be trimmed, so do not put the jigsaw away too far. The resulting segments are carefully rubbed with sandpaper so as not to injure your hands later. The chipboard is rubbed from the edges to the center to avoid any external damage to the laminate. At this stage, all the wood must be treated with an antiseptic against moisture and insects. This measure is mandatory if you need to extend the service life of the chair. Return to the table of contents</a>

Main work activity

Tools and materials: Chair upholstery diagram.

Chair upholstery diagram.

- electric jigsaw;

- Particleboard;

- bar;

- Screwdriver;

- screws and screws;

- folding and rotational loops;

- foam rubber;

- upholstery;

- a stapler.

Now it's time for the main assembly.It starts exactly at the moment when the antiseptic dries completely. At the very beginning of this process, you need to screw 4 bars (70 and 90 cm) to each plate from below along the perimeter, and in order for the joint to be possible, you need to make oblique cuts at 45 degrees. For fastening, holes of a small diameter are initially drilled, after which it will be possible to fix the structure with screws at intervals of 25-30 cm. When the main elements are ready, you need to assemble the supporting structure for the headrest:

One of the following is mounted into the finished support structure:previously prepared boards. The height is 20 cm above the floor, and the fixation points pass through the legs at the headboard (2 pcs.). For reliable coupling, ordinary loops are used, which will not allow excess tension to be created in the material, and at the same time will ensure the free lifting of the headrest into place. In order for the structure to stop at the desired level at a height of 20 cm when lowered to the selected place, blockers are installed. They can be made of galvanized corners (2 pcs. in total) with plastic attachments. For fixing, you will need 2 self-tapping screws for each. 2 legs (23 cm) are attached to the remaining 2 segments, which will be on the opposite side from the headboard during installation. This arrangement will allow the load to be distributed evenly. Fastening is carried out on ordinary furniture hinges, which will lower the support under their own weight when unfolding and similarly select during assembly. In order to connect the sections together, you will need a little ingenuity. The hinges between the headboard and the central section are attached to the sides (the rotating hinges are attached to the support structure) so that when assembled the central section can be laid in place of the headboard. After this, the footboard is attached with hinges from below, which when folded turns out to be the legs at the bottom. Return to contents</a>

Shutdown

At the very end, you need to lay it on each segmentbatting or foam rubber, then tighten it with any upholstery fabric, and fix it along the edge with a special stapler. The headboard is closed on both sides. All stages of making a chair-armchair are quite fast, so you can start in the morning, and by night the product will be finished. Although most often it takes 2 days. With high-quality manufacturing, this piece of furniture will last at least 10 years, and with proper use, 30.</ ul>