For quality production of wicker furniturewith their own hands, it is necessary to comply with certain requirements, so that the chair or chair can be made quickly enough. The use of natural materials for weaving involves the observance of all the structural features of the type of furniture being manufactured, for example, chairs.  Wicker chair made of naturalmaterials, unpretentious in the care and perfectly suited to any style of the room. Weaving of furniture is an exclusive kind of activity on creation of subjects of an interior. If the design is chosen correctly, the wicker furniture will look original in an elegant style, differing in particular reliability and simplicity in care and use. As the number of owners of cottages and country houses increases every year, their desire to design rooms in a naturalistic style requires appropriate furniture, which can be woven.

Wicker chair made of naturalmaterials, unpretentious in the care and perfectly suited to any style of the room. Weaving of furniture is an exclusive kind of activity on creation of subjects of an interior. If the design is chosen correctly, the wicker furniture will look original in an elegant style, differing in particular reliability and simplicity in care and use. As the number of owners of cottages and country houses increases every year, their desire to design rooms in a naturalistic style requires appropriate furniture, which can be woven.

Materials for making a wicker chair

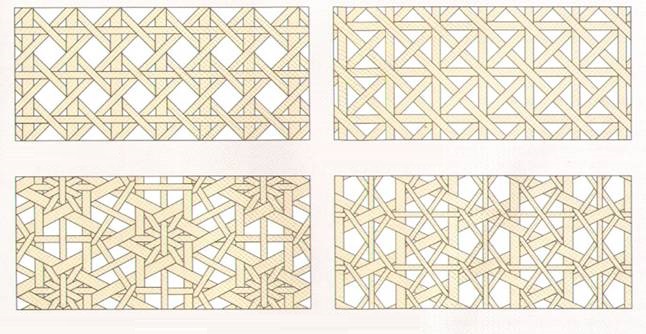

Layout of the rocking chair with your own hands. You should pay attention to the differences in the methods of weaving. Allocate the following methods:

Layout of the rocking chair with your own hands. You should pay attention to the differences in the methods of weaving. Allocate the following methods:

The entire process of making wicker chairs is connectedwith the implementation of original patterns, by combining various methods or using only one kind of weaving. The durability of wicker furniture is determined not only by the nature of the assembly of all the elements that can be detachable and integral, but also the material. When using permanent joints in the process of assembling the braided elements, glue or nails are used, which gives the finished products a special durability.  Chair weaving options with different combinationsthin and thick rods. Most tree species are suitable for the production of wicker furniture. Willow, bird cherry, alder, hazel, raspberry, rakita, etc. are used. Created can be woven from grapevine, etc., it can be covered with rattan. For beginners, it is recommended to weave from bird cherry twigs, which are optimally amenable to bending. You can always prepare pieces of small twigs or ribbons from bird cherry, which will have a natural shine and a spectacular shade. To simplify the process of assembling wicker furniture, detachable elements are used, but their number will be rather limited depending on the type of furniture. Back to the table of contents</a> How to properly prepare the rods forweaving? Usually the preparation of rods for weaving starts from October to winter, when frosts come, and also in the spring. These seasons are due to the fact that wooden rods can be easily cleaned and stored in a dry condition for a very long time. The delicate weaving of the chairs is associated with the use of thin rods, which are cut in spring. If the core of twigs is thin, this indicates the quality of the material for weaving. If the rods have a thick core, then they make skeletons for wicker structures, for example, arbors. The width of the sheet may indicate the flexibility of the bars, the narrower the sheet, the greater the bending of the material, the product will appear more delicate. The efficiency of the products depends on the technology of processing the rod, from which the white bars are produced.

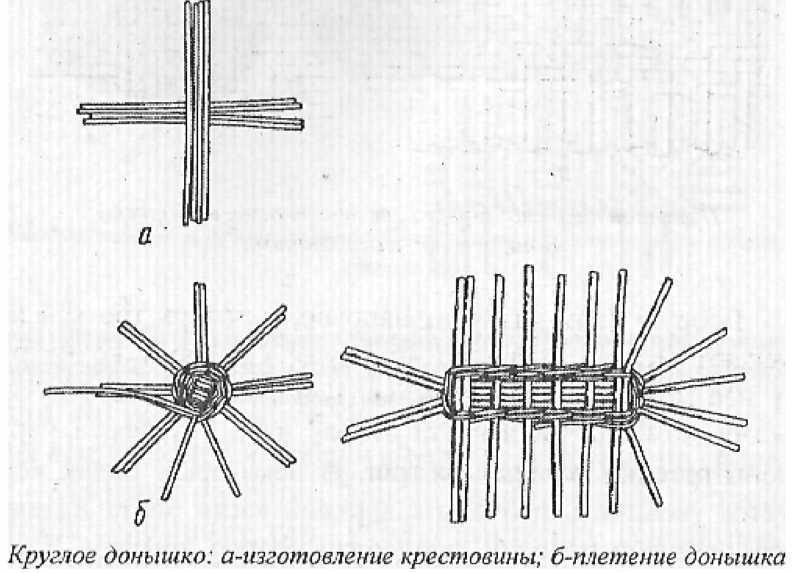

Chair weaving options with different combinationsthin and thick rods. Most tree species are suitable for the production of wicker furniture. Willow, bird cherry, alder, hazel, raspberry, rakita, etc. are used. Created can be woven from grapevine, etc., it can be covered with rattan. For beginners, it is recommended to weave from bird cherry twigs, which are optimally amenable to bending. You can always prepare pieces of small twigs or ribbons from bird cherry, which will have a natural shine and a spectacular shade. To simplify the process of assembling wicker furniture, detachable elements are used, but their number will be rather limited depending on the type of furniture. Back to the table of contents</a> How to properly prepare the rods forweaving? Usually the preparation of rods for weaving starts from October to winter, when frosts come, and also in the spring. These seasons are due to the fact that wooden rods can be easily cleaned and stored in a dry condition for a very long time. The delicate weaving of the chairs is associated with the use of thin rods, which are cut in spring. If the core of twigs is thin, this indicates the quality of the material for weaving. If the rods have a thick core, then they make skeletons for wicker structures, for example, arbors. The width of the sheet may indicate the flexibility of the bars, the narrower the sheet, the greater the bending of the material, the product will appear more delicate. The efficiency of the products depends on the technology of processing the rod, from which the white bars are produced.  Weaving the round bottom of the chair. The method is associated with the digestion of material in a large container, where hot boiled water is poured. In the container should be lowered rods and cook them for about an hour on high heat. To get light shades, you can weld the rods for about two hours, and the dark color of the material is obtained by boiling it in the same water for 4 hours or more. When the rods are already cooked, you can begin to scrape off the bark from them. Otherwise, the future material will lose its aesthetic connotation. To remove the bark, use a cleavage or rough gloves. The product will be most effective if you use glossy ribbons stripped from bars of bars, which are divided into 2 or 4 parts with a knife or a small-sized scoop, together with the rods. Back to contents</a>

Weaving the round bottom of the chair. The method is associated with the digestion of material in a large container, where hot boiled water is poured. In the container should be lowered rods and cook them for about an hour on high heat. To get light shades, you can weld the rods for about two hours, and the dark color of the material is obtained by boiling it in the same water for 4 hours or more. When the rods are already cooked, you can begin to scrape off the bark from them. Otherwise, the future material will lose its aesthetic connotation. To remove the bark, use a cleavage or rough gloves. The product will be most effective if you use glossy ribbons stripped from bars of bars, which are divided into 2 or 4 parts with a knife or a small-sized scoop, together with the rods. Back to contents</a>

How to create a chair with your own hands?

Additional braiding of the base of the bottom: a-general view; б-braid of pillars of the bottom with wicker ribbon (front side); в-fastening of the ends of the willow ribbons (the unilateral side). Wicker rest seating designs include several elements, ranging from backrests to seats with armrests. The frame can be made of sticks of sufficient thickness. In this case, the braid is left in the places where the parts are articulated. Decorative designs have certain characteristics, since the functions of the armrests are related to convenience. A comfortable rest in the chair will be provided. To make the seat comfortable, the frame is made by strengthening the legs to the thong, that is, its crosspiece. After this, work should be done on tightening the chair's footstep. Then perform the installation of the backrest in its upper part, the seats of the chair from the rods running across. Forming the armrests of the chair can be done using pre-treated elements, which are soaked willow sticks that are arched. In this way, the original chairs are made from rods. For example, you can make a hanging armchair on your own. It will be combined with the use of willow rods and synthetic ropes.

Additional braiding of the base of the bottom: a-general view; б-braid of pillars of the bottom with wicker ribbon (front side); в-fastening of the ends of the willow ribbons (the unilateral side). Wicker rest seating designs include several elements, ranging from backrests to seats with armrests. The frame can be made of sticks of sufficient thickness. In this case, the braid is left in the places where the parts are articulated. Decorative designs have certain characteristics, since the functions of the armrests are related to convenience. A comfortable rest in the chair will be provided. To make the seat comfortable, the frame is made by strengthening the legs to the thong, that is, its crosspiece. After this, work should be done on tightening the chair's footstep. Then perform the installation of the backrest in its upper part, the seats of the chair from the rods running across. Forming the armrests of the chair can be done using pre-treated elements, which are soaked willow sticks that are arched. In this way, the original chairs are made from rods. For example, you can make a hanging armchair on your own. It will be combined with the use of willow rods and synthetic ropes.  Stages of weaving of the oblique pigtail. In the process of weaving, the following tools and materials will be needed:

Stages of weaving of the oblique pigtail. In the process of weaving, the following tools and materials will be needed:

Initially, they are engaged in harvesting willow branches. Usually they can be found near ponds or rivers. It's good when they are not too far from a country house or villa. You can collect the branches by cutting them first from the trees. Diameter of rods should be from 10 to 20 mm, they will need about 300-400 pieces. After the preparation of the material for the weaving starts to work. Back to contents</a>

How to make a round chair for rest?

Starting the manufacture of a hanging chair,round seat based on the cross. It is made of thicker rods by bandaging them crosswise with a twine, which is pre-lubricated with glue. After this, the cross should be rounded with a thinner rod. For quality, you can use round-nosed pliers, pulling the rod from below and from above alternately. As the cross bars are fastened with rods, the size of the seat diameter should be periodically measured using a ruler, continuing the process of weaving. It is finished when the diameter of the seat is about 70 cm. After this, using the twine, the last rod is tied to the end with the end, which was the last. The outer circle is tied with a twine and an awl, through which it is stretched through the last ring. The greatest strength can be achieved with a twine, which needs to be glued with glue. For weaving the back of the seat use a metal-plastic hoop, on which it is necessary to tie the grid in the form of a pattern "chessboard". Pre-pin the rope from the synthetic material with a pin to the hoop. When the rope is thrown over the hoop, it is ensured that the cord is shorter at one end and longer on the other. The second cord is fastened in the same way. Next, connect the seat with the backrest and hang the chair with their own hands on the slings to the tree.