During apartment renovations, it is increasingly commonself-leveling floors are used. They are also called a flooded floor, self-leveling mixture, self-leveling floor, etc. This can be arranged in any of the rooms. The work is facilitated by the fact that the mixture is applied to the surface in a layer of 1-100 mm and levels itself. As a result, a perfectly flat and smooth surface appears, in which there are no differences in height, air bubbles. Any floor covering made of ceramic tiles, laminate, parquet can be perfectly laid on such an ideal surface. Self-leveling building mixtures for floor construction can also serve as a finishing floor covering, giving the surface glossy or matte shades. Self-leveling floor is wear-resistant and moisture-resistant. By using 3D technology, you can get amazing pictures on the floor.

Self-leveling floor is wear-resistant and moisture-resistant. By using 3D technology, you can get amazing pictures on the floor.

Distinctive features of the filling floor

- great durability;

- very strong surface;

- resistance to wear;

- water resistance;

- non-adherence to dust accumulation.

The floor mixture is easy to lay on various bases. It is easier to prepare, applied to the base and dries much faster than any other construction solution. Return to contents</a>

Materials for work

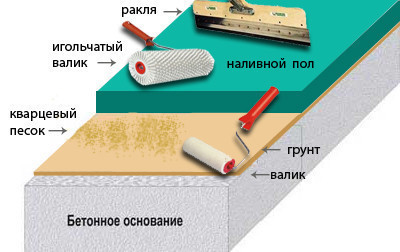

To install a self-leveling floor, you need to prepare: Essential tools for self-leveling floors.

Essential tools for self-leveling floors.

- bags with a dry mixture;

- priming composition;

- putty;

- damper tape;

- dowels;

- a bucket with a capacity of 25-40 liters;

- a drill with a nozzle-mixer;

- putty knife;

- Needle roller;

- level.

Necessary tools. You need to walk on a freshly poured floor in special shoes called paint shoes. Return to contents</a>

The order of performance of works

All installation work consists of the following stages:

Scheme of self-leveling self-leveling floor.Preparatory work includes removing elevation changes, traces of old concrete mix, and removing oil stains from the surface of the old floor. Remove all baseboards and door frames. Remove dust and concrete particles with a wire brush, broom, or vacuum cleaner. Dry the concrete base. Finish the work by gluing the corners between the floor and walls with a special damper tape. Remove varnish, wax, and paint from wooden surfaces. This is best done with a grinder and vacuum cleaner. The humidity of the wooden base should not exceed 10%. Treat all cracks with putty and dry. Beacons, such as dowels and screws, may be needed to evenly distribute the finished self-leveling mass. Adjust the horizontality of the future floor with a long rule installed on the screw heads. To do this, install a level on the rule. Prime the surface of the floor base for better spreading of the working mixture. This is done with a roller or a paint brush. The primer layer needs to be dried and a new layer applied to it. After 24 hours, you can pour in the working mixture. The mixture is prepared immediately before use, since its drying time is quite short. It is diluted in accordance with the manufacturer's recommendations. It should be remembered that dry components are poured into water. It is recommended to stir the composition for about 10 minutes with a drill with a construction mixer. The finished composition is applied at a temperature of 15 to 25 °. The entire floor is poured in one go, the next portions of the solution should be ready within no more than 10 minutes. In a large room, you will have to involve several assistants for work. Pouring the floor begins from the farthest corner from the entrance door. The solution is leveled on the floor with a spatula and rolled with a needle roller to remove air bubbles. The spikes on the soles of the paint shoes also help remove air from the mixture. Complete drying of the poured floor occurs in 2-3 days. The final floor covering can be laid after 5 days. The floor heating system, if it was installed before pouring, is connected a week after the floor has completely dried. Making a self-leveling floor with your own hands is a task that is quite feasible for a home craftsman. There are quite a lot of materials for this work on sale. No special tools are required. The main thing is to carefully follow all the instructions for carrying out preparatory work and mixing the working compositions.</ ul>

Scheme of self-leveling self-leveling floor.Preparatory work includes removing elevation changes, traces of old concrete mix, and removing oil stains from the surface of the old floor. Remove all baseboards and door frames. Remove dust and concrete particles with a wire brush, broom, or vacuum cleaner. Dry the concrete base. Finish the work by gluing the corners between the floor and walls with a special damper tape. Remove varnish, wax, and paint from wooden surfaces. This is best done with a grinder and vacuum cleaner. The humidity of the wooden base should not exceed 10%. Treat all cracks with putty and dry. Beacons, such as dowels and screws, may be needed to evenly distribute the finished self-leveling mass. Adjust the horizontality of the future floor with a long rule installed on the screw heads. To do this, install a level on the rule. Prime the surface of the floor base for better spreading of the working mixture. This is done with a roller or a paint brush. The primer layer needs to be dried and a new layer applied to it. After 24 hours, you can pour in the working mixture. The mixture is prepared immediately before use, since its drying time is quite short. It is diluted in accordance with the manufacturer's recommendations. It should be remembered that dry components are poured into water. It is recommended to stir the composition for about 10 minutes with a drill with a construction mixer. The finished composition is applied at a temperature of 15 to 25 °. The entire floor is poured in one go, the next portions of the solution should be ready within no more than 10 minutes. In a large room, you will have to involve several assistants for work. Pouring the floor begins from the farthest corner from the entrance door. The solution is leveled on the floor with a spatula and rolled with a needle roller to remove air bubbles. The spikes on the soles of the paint shoes also help remove air from the mixture. Complete drying of the poured floor occurs in 2-3 days. The final floor covering can be laid after 5 days. The floor heating system, if it was installed before pouring, is connected a week after the floor has completely dried. Making a self-leveling floor with your own hands is a task that is quite feasible for a home craftsman. There are quite a lot of materials for this work on sale. No special tools are required. The main thing is to carefully follow all the instructions for carrying out preparatory work and mixing the working compositions.</ ul>