Drywall cabinets are not thatrarity, but their appearance can rarely be distinguished from conventional built-in structures. Such cabinets often replace partitions or interior walls, which makes it possible to use space more efficiently. It is not so difficult to construct a plasterboard cabinet with your own hands. First, you will have to draw up a project, purchase the appropriate materials. After that, the frame is erected, covered with plasterboard sheets, and finishing work is carried out. Shelves for such a cabinet can be made from various materials; if you have experience, it is recommended to conduct wiring and install small LED lights that will act as a backlight. A do-it-yourself plasterboard wardrobe partition will cost much less than a professional's work.

A do-it-yourself plasterboard wardrobe partition will cost much less than a professional's work.

Advantages of plasterboard cabinets for living room and corridor

Drywall has many advantages, including:

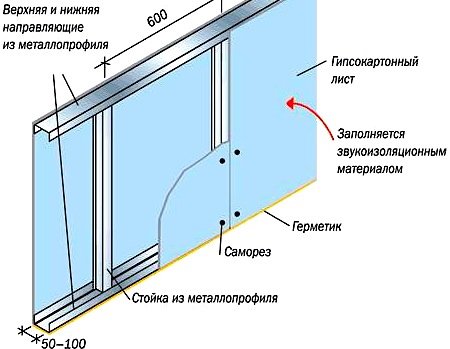

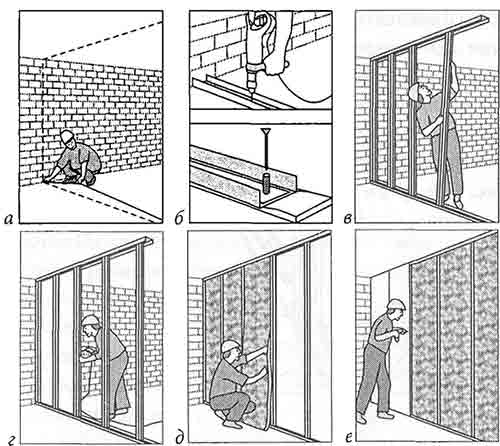

Partitions made of plasterboard.So where to start building a cabinet? It is important to have a drawing and assembly diagram on hand. Today, finding such diagrams is not a problem. Ready-made solutions are offered, among which you can choose the most suitable one. If there is no such diagram, then you can order it. When selecting a drawing, you need to take into account the exact dimensions of the room and the place where you plan to install the cabinet. The drawing shows all the dimensions, the position of the shelves, doors, drawers, etc. When the drawing is ready, you need to start applying markings to the surface of the floor, walls, ceiling. Lines for the guide profile are marked, this is done using plumb lines, a building level, a metal ruler and a pencil. If necessary, part of the finishing is removed from the walls or floor, although usually such measures are not required at all. Return to contents</a>

Partitions made of plasterboard.So where to start building a cabinet? It is important to have a drawing and assembly diagram on hand. Today, finding such diagrams is not a problem. Ready-made solutions are offered, among which you can choose the most suitable one. If there is no such diagram, then you can order it. When selecting a drawing, you need to take into account the exact dimensions of the room and the place where you plan to install the cabinet. The drawing shows all the dimensions, the position of the shelves, doors, drawers, etc. When the drawing is ready, you need to start applying markings to the surface of the floor, walls, ceiling. Lines for the guide profile are marked, this is done using plumb lines, a building level, a metal ruler and a pencil. If necessary, part of the finishing is removed from the walls or floor, although usually such measures are not required at all. Return to contents</a>

Mounting of the frame for partitions

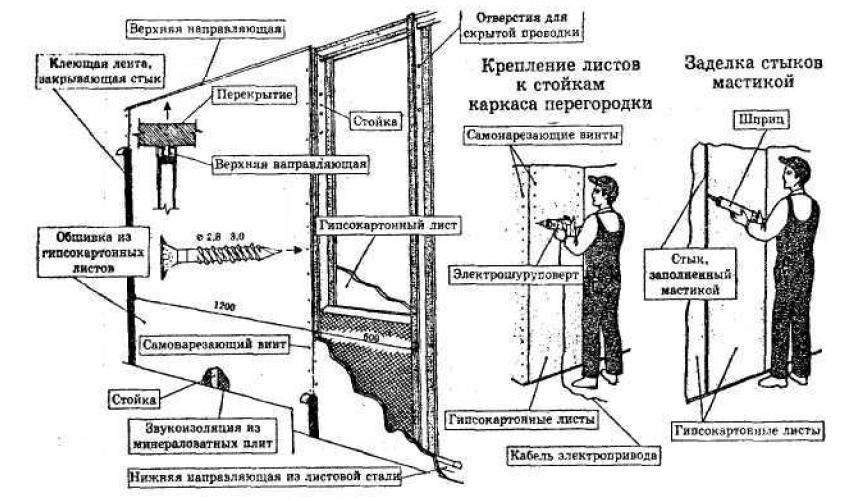

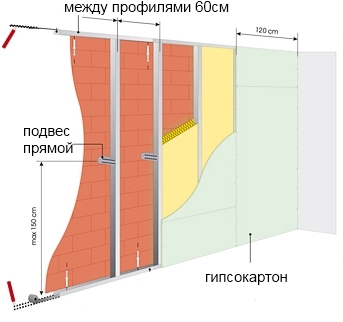

Types of profiles for plasterboard.A preliminary drawing is used to assemble the frame; you cannot start work without it. The structure is assembled from metal profiles specially designed for plasterboard; it is not recommended to choose wood, although it is possible. The wood should be thoroughly dried, treated with an antiseptic, but there are no such problems with a metal profile. If you use wooden blocks, they can deform when drying. The frame slats are not always able to withstand the load. Therefore, it is better to immediately pay a little extra and buy metal profiles. Galvanized steel and aluminum are not always suitable for such work. The frame is fastened along the marked lines. First, the profiles are mounted to the ceiling and floor, after which the guides are installed to the walls. The step between the vertical posts should not be large. After this, the hangers are mounted, to which the structure posts will be attached, they are installed in the guides on the floor and on the ceiling. In those places where the structure will touch the wall, a special sealing tape is used. This allows you to make the frame more reliable, to prevent deformations during operation. To provide additional rigidity, horizontal profiles are used, they are fixed on the racks. All fastening is carried out using self-tapping screws for metal. During assembly, it is worth preparing the guides for the drawers, provide shelves. If heavy loads are expected, it is necessary to additionally strengthen the racks and guides. Return to the table of contents</a>

Types of profiles for plasterboard.A preliminary drawing is used to assemble the frame; you cannot start work without it. The structure is assembled from metal profiles specially designed for plasterboard; it is not recommended to choose wood, although it is possible. The wood should be thoroughly dried, treated with an antiseptic, but there are no such problems with a metal profile. If you use wooden blocks, they can deform when drying. The frame slats are not always able to withstand the load. Therefore, it is better to immediately pay a little extra and buy metal profiles. Galvanized steel and aluminum are not always suitable for such work. The frame is fastened along the marked lines. First, the profiles are mounted to the ceiling and floor, after which the guides are installed to the walls. The step between the vertical posts should not be large. After this, the hangers are mounted, to which the structure posts will be attached, they are installed in the guides on the floor and on the ceiling. In those places where the structure will touch the wall, a special sealing tape is used. This allows you to make the frame more reliable, to prevent deformations during operation. To provide additional rigidity, horizontal profiles are used, they are fixed on the racks. All fastening is carried out using self-tapping screws for metal. During assembly, it is worth preparing the guides for the drawers, provide shelves. If heavy loads are expected, it is necessary to additionally strengthen the racks and guides. Return to the table of contents</a>

Sheathing of the finished frame

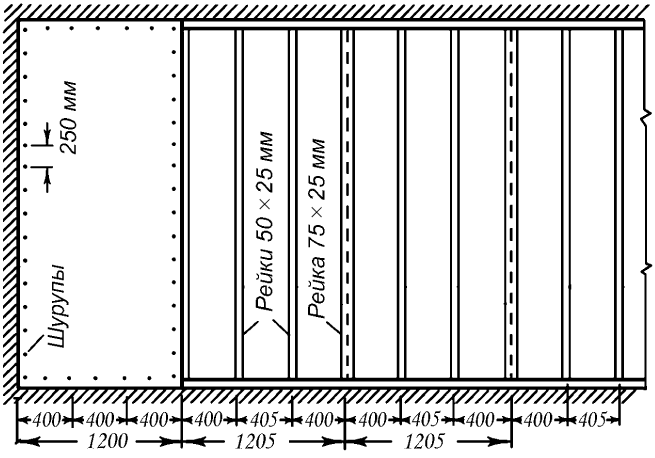

Scheme of plasterboard cladding on woodframe. Wall cladding is easy, for this you need to pre-mark and cut the sheets. Such marking is done after the frame is ready to avoid unnecessary material costs. The marking is applied with a simple pencil and a ruler, the cut is made with a sharp knife, hacksaw or jigsaw. After cutting, all edges are carefully processed so that they are even. Drywall sheets are fastened to the frame with self-tapping screws, the cladding is installed quickly. The heads of the screws should be slightly recessed during fastening, they should not protrude above the surface. During work, care must be taken not to damage the surface. The order of work is not limited, but it is best to start with complex, hard-to-reach surfaces, and then perform the cladding of the main part. This will speed up the work, make it better. After that, it is necessary to check the horizontality and verticality of all structures again with a building level. If everything is in order, then you can proceed to the finishing stage, which includes preparation and decorative work. Return to contents</a>Finishing works

Scheme of plasterboard cladding on woodframe. Wall cladding is easy, for this you need to pre-mark and cut the sheets. Such marking is done after the frame is ready to avoid unnecessary material costs. The marking is applied with a simple pencil and a ruler, the cut is made with a sharp knife, hacksaw or jigsaw. After cutting, all edges are carefully processed so that they are even. Drywall sheets are fastened to the frame with self-tapping screws, the cladding is installed quickly. The heads of the screws should be slightly recessed during fastening, they should not protrude above the surface. During work, care must be taken not to damage the surface. The order of work is not limited, but it is best to start with complex, hard-to-reach surfaces, and then perform the cladding of the main part. This will speed up the work, make it better. After that, it is necessary to check the horizontality and verticality of all structures again with a building level. If everything is in order, then you can proceed to the finishing stage, which includes preparation and decorative work. Return to contents</a>Finishing works Installation diagram of a plasterboard partition.The final stage of making a wardrobe from plasterboard sheets is surface finishing. There are many options, it all depends on the requirements for the furniture surface, what is the style of the interior. Before starting the finishing, the surface must be prepared. To do this, all the joints of the sheets and fastening points are filled. Usually 2 layers of putty are applied. The 1st - on the joints and fastening points with a narrow metal spatula, literally pressing the mass. Next, you need to use a special reinforcing tape, which prevents cracking during drying, after which the 2nd layer is applied. When the 2nd layer dries, it is necessary to clean the surface from excess so that it becomes perfectly flat and smooth. After this, you can already do the decorative finishing. Here you can show your imagination to the fullest. The simplest is to paint the surface (Fig. 2) or glue wallpaper, but you can also use decorative plaster. It all depends on the overall interior and whether it is necessary to highlight the structure or, on the contrary, hide it. For corridors, the option of finishing with ceramic tiles is suitable. For the latter option, it is necessary to provide a stronger profile at the design stage so that it can withstand the weight of the tiles. Return to the table of contents</a>

Installation diagram of a plasterboard partition.The final stage of making a wardrobe from plasterboard sheets is surface finishing. There are many options, it all depends on the requirements for the furniture surface, what is the style of the interior. Before starting the finishing, the surface must be prepared. To do this, all the joints of the sheets and fastening points are filled. Usually 2 layers of putty are applied. The 1st - on the joints and fastening points with a narrow metal spatula, literally pressing the mass. Next, you need to use a special reinforcing tape, which prevents cracking during drying, after which the 2nd layer is applied. When the 2nd layer dries, it is necessary to clean the surface from excess so that it becomes perfectly flat and smooth. After this, you can already do the decorative finishing. Here you can show your imagination to the fullest. The simplest is to paint the surface (Fig. 2) or glue wallpaper, but you can also use decorative plaster. It all depends on the overall interior and whether it is necessary to highlight the structure or, on the contrary, hide it. For corridors, the option of finishing with ceramic tiles is suitable. For the latter option, it is necessary to provide a stronger profile at the design stage so that it can withstand the weight of the tiles. Return to the table of contents</a>

Tools and materials for work

To make your own partition cabinetsfrom plasterboard, it is necessary to prepare materials and tools. Nothing expensive and complicated is required, but before buying it is necessary to carefully calculate everything. For convenience, a drawing is made in advance. Profiles, plasterboard sheets and fastening elements are calculated based on the dimensions and design features. The presence of shelves and doors, drawers is provided. Tools required for work:construction laser level, pencil, hammer drill, screwdriver, metal shears, metal spatula. The following tools and materials are required for the work:

Tools required for work:construction laser level, pencil, hammer drill, screwdriver, metal shears, metal spatula. The following tools and materials are required for the work:

- sheets of plasterboard;

- building laser level;

- plumb bob;

- metal ruler, measuring tape, simple pencil;

- metal corner;

- Screwdriver;

- perforator (this is determined in advance during calculations and examination of walls);

- scissors for metal for cutting profiles;

- set of drills for work on concrete and metal (if the wall is brick, it is additionally necessary to prepare special drills and under it);

- a metal spatula;

- self-tapping screws;

- putty;

- decorative finishing materials (paint, plaster or something else).

It is best to order sliding doorsseparately, such services are provided today by many furniture factories and companies engaged in the installation of built-in furniture. This will not only cost less, but also be of higher quality, since it is not always possible to assemble such doors with your own hands so that they do not warp or fall out. Return to contents</a>

Variants of plasterboard cabinets

Installation of plasterboard profiles in the bedroom.Drywall cabinets can take various shapes, the ease of their installation and the possibility of making a design of various types allows you to implement the most daring projects (Fig. 3). Today you can find ready-made projects. A partition cabinet is popular, it allows you to separate 2 rooms. Usually, such a cabinet is placed in the hallway, its back wall is made solid, painted or decorated in the style of the living room. Its open part or doors face the hallway so that you can use the cabinet to store various things. The partition is convenient because it can take any shape, doors can be installed on 2 sides or an open cabinet can be built. There are many options, you can easily choose a suitable cabinet for a specific situation. From the design features that distinguish such a partition, it is necessary to note the depth of the cabinet. This value should be at least 60 cm so that you can comfortably place clothes. For side panels, the bottom, an additional 10 cm is left taking into account the fastening of the structure. Such a reserve must be provided if sliding doors are used.

Installation of plasterboard profiles in the bedroom.Drywall cabinets can take various shapes, the ease of their installation and the possibility of making a design of various types allows you to implement the most daring projects (Fig. 3). Today you can find ready-made projects. A partition cabinet is popular, it allows you to separate 2 rooms. Usually, such a cabinet is placed in the hallway, its back wall is made solid, painted or decorated in the style of the living room. Its open part or doors face the hallway so that you can use the cabinet to store various things. The partition is convenient because it can take any shape, doors can be installed on 2 sides or an open cabinet can be built. There are many options, you can easily choose a suitable cabinet for a specific situation. From the design features that distinguish such a partition, it is necessary to note the depth of the cabinet. This value should be at least 60 cm so that you can comfortably place clothes. For side panels, the bottom, an additional 10 cm is left taking into account the fastening of the structure. Such a reserve must be provided if sliding doors are used. Types of plasterboard partitions.A simpler option than a partition is a built-in plasterboard closet. The work here is simpler, since there is no need to build a complex frame, in fact, it is necessary to complete the wall paneling of the niche, and then install a frame for the shelves and compartments of the future closet. This option is suitable for hallways and living rooms. It is convenient, there are usually no problems with the design. The depth should be sufficient to fit all the shelves. Of the unusual, but very convenient designs, we can note the corner closet. It allows you to save space, provide a place for storing things, using areas that are usually not used for this. This design has many advantages, it allows you to place things without wasting useful space at all. The appearance of the room becomes more attractive, it becomes possible to avoid cluttering up furniture, which is typical for a linear standard arrangement. The same plasterboard is used for the front doors, it can be decorated using various techniques. A plasterboard closet is a simple and useful design, especially if it is used as a partition. It is not so difficult to make it yourself. It is important to choose the right scheme, make a drawing yourself or use a ready-made version. There are a large number of different options on the Internet, if none of them suits you, then you can make it yourself based on the ready-made one.

Types of plasterboard partitions.A simpler option than a partition is a built-in plasterboard closet. The work here is simpler, since there is no need to build a complex frame, in fact, it is necessary to complete the wall paneling of the niche, and then install a frame for the shelves and compartments of the future closet. This option is suitable for hallways and living rooms. It is convenient, there are usually no problems with the design. The depth should be sufficient to fit all the shelves. Of the unusual, but very convenient designs, we can note the corner closet. It allows you to save space, provide a place for storing things, using areas that are usually not used for this. This design has many advantages, it allows you to place things without wasting useful space at all. The appearance of the room becomes more attractive, it becomes possible to avoid cluttering up furniture, which is typical for a linear standard arrangement. The same plasterboard is used for the front doors, it can be decorated using various techniques. A plasterboard closet is a simple and useful design, especially if it is used as a partition. It is not so difficult to make it yourself. It is important to choose the right scheme, make a drawing yourself or use a ready-made version. There are a large number of different options on the Internet, if none of them suits you, then you can make it yourself based on the ready-made one.