When choosing a material for a partition, more and more oftenstop at plasterboard. And this is not surprising. Work with plasterboard is very simple, you can do the installation yourself. In addition, it is one of the cheapest materials, which means you can save a lot. However, in order not to be disappointed, you need to approach the installation of the partition wisely. Construction of a partition made of plasterboard.

Construction of a partition made of plasterboard.

Advantages of using drywall

Return to Contents</a>

Necessary materials and tools

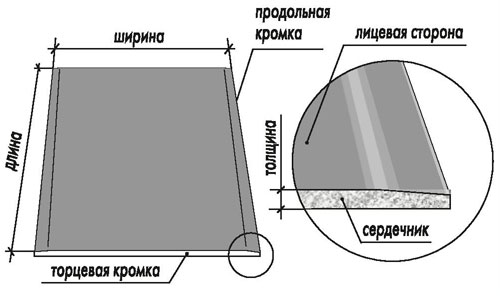

To work you will need: Scheme of plasterboard sheet.

Scheme of plasterboard sheet.

- profiles;

- Rack profiles;

- sheets of plasterboard;

- drill;

- Screwdriver;

- self-tapping screws for metal;

- dowels;

- level;

- plumb bob;

- a tape-sealant;

- roulette;

- knife for cutting plasterboard;

- soundproof material;

- putty;

- spatulas;

- building mesh;

- grater with emery cloth.

Return to Contents</a>

Assembling the frame, marking and mounting the profile

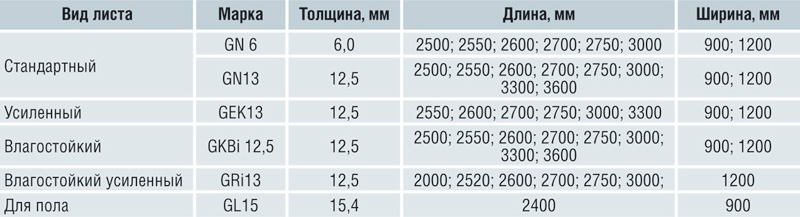

Physical and technical characteristicsplasterboard sheets. Plasterboard cannot hold on to air. The role of support is performed by the frame. It can be assembled from metal profiles or wooden bars. However, it is worth giving preference to the first option, as it is more durable and unpretentious. In addition, a full-fledged wall with a door is a significant load on the sheathing, and the wood can crack over time. The reliability, evenness and beauty of the entire structure will depend on the correct marking. First, two parallel lines must be applied to the floor and ceiling. They must be in the same plane, otherwise the wall will be distorted. First, a line is drawn on the ceiling from one wall to another. Then, using a plumb line, it is transferred to the floor. That is, several places are selected on the ceiling, plumb lines are lowered from them and points are marked on the floor. Then the resulting "dotted line" is connected. You can do the opposite: first draw a line on the floor, and then transfer it to the ceiling. After that, the lines are connected along the walls. A profile is attached along all lines. On the floor and ceiling - a guide is required. Installation is carried out using self-tapping screws for metal. The distance between them is 30-40 cm. Such a frequent arrangement of self-tapping screws is necessary, since these are the profiles that will hold the entire partition.

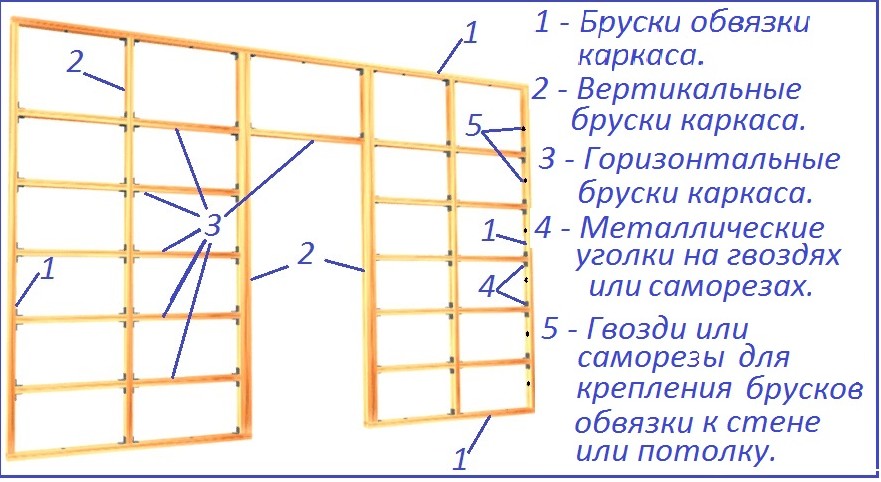

Physical and technical characteristicsplasterboard sheets. Plasterboard cannot hold on to air. The role of support is performed by the frame. It can be assembled from metal profiles or wooden bars. However, it is worth giving preference to the first option, as it is more durable and unpretentious. In addition, a full-fledged wall with a door is a significant load on the sheathing, and the wood can crack over time. The reliability, evenness and beauty of the entire structure will depend on the correct marking. First, two parallel lines must be applied to the floor and ceiling. They must be in the same plane, otherwise the wall will be distorted. First, a line is drawn on the ceiling from one wall to another. Then, using a plumb line, it is transferred to the floor. That is, several places are selected on the ceiling, plumb lines are lowered from them and points are marked on the floor. Then the resulting "dotted line" is connected. You can do the opposite: first draw a line on the floor, and then transfer it to the ceiling. After that, the lines are connected along the walls. A profile is attached along all lines. On the floor and ceiling - a guide is required. Installation is carried out using self-tapping screws for metal. The distance between them is 30-40 cm. Such a frequent arrangement of self-tapping screws is necessary, since these are the profiles that will hold the entire partition. Construction of a wooden frame for plasterboard.They must be sealed with a sealing tape before installation. It minimizes the distance between the profile and the walls, floor, ceiling and improves sound insulation. The tape helps to avoid cracking and the formation of cracks. That is, it will act as a compensation layer. Then the rack profile is inserted into the guide profile. The calculation is simple: 3 supports are enough for 1 vertically installed sheet of plasterboard. The edges of the sheet will lie on 2, and another 1 in the middle. Thus, the profiles will be located every 60 cm. If a large load is planned, then you can increase the number of supports to 4, placing them every 40 cm. All vertical posts are fastened with self-tapping screws to the ceiling and floor profiles. Lastly, if necessary, the horizontal profile is installed. It must be in cases where there will be not only vertical but also horizontal seams on the walls, since the sheets can only be joined on the profile. At this stage, it is necessary to provide for embedded parts - an additional profile for fastening shelves and other elements. You cannot simply hang anything on the plasterboard. The frame is ready. If it was nevertheless decided to use wooden bars, then the principle of assembling the lathing from slats is no different from that given above. Return to the table of contents</a>

Construction of a wooden frame for plasterboard.They must be sealed with a sealing tape before installation. It minimizes the distance between the profile and the walls, floor, ceiling and improves sound insulation. The tape helps to avoid cracking and the formation of cracks. That is, it will act as a compensation layer. Then the rack profile is inserted into the guide profile. The calculation is simple: 3 supports are enough for 1 vertically installed sheet of plasterboard. The edges of the sheet will lie on 2, and another 1 in the middle. Thus, the profiles will be located every 60 cm. If a large load is planned, then you can increase the number of supports to 4, placing them every 40 cm. All vertical posts are fastened with self-tapping screws to the ceiling and floor profiles. Lastly, if necessary, the horizontal profile is installed. It must be in cases where there will be not only vertical but also horizontal seams on the walls, since the sheets can only be joined on the profile. At this stage, it is necessary to provide for embedded parts - an additional profile for fastening shelves and other elements. You cannot simply hang anything on the plasterboard. The frame is ready. If it was nevertheless decided to use wooden bars, then the principle of assembling the lathing from slats is no different from that given above. Return to the table of contents</a>

Curvilinear partitions

Methods of bending plasterboard: wet and dry.Sometimes it is necessary to make a plasterboard partition at an angle. The installation of such a wall is practically no different, you just need to immediately decide on the configuration of the room. In this case, the necessary contour is immediately drawn on the floor and ceiling. The corner itself must be reinforced: there must be vertical posts on both sides of the profile joint. Otherwise, the assembly of the frame will not be different: vertical profiles are brought in, and then horizontal ones are installed. There may be several corners. In this case, it is necessary to strengthen each of them with two rack profiles. Return to the table of contents</a>

Methods of bending plasterboard: wet and dry.Sometimes it is necessary to make a plasterboard partition at an angle. The installation of such a wall is practically no different, you just need to immediately decide on the configuration of the room. In this case, the necessary contour is immediately drawn on the floor and ceiling. The corner itself must be reinforced: there must be vertical posts on both sides of the profile joint. Otherwise, the assembly of the frame will not be different: vertical profiles are brought in, and then horizontal ones are installed. There may be several corners. In this case, it is necessary to strengthen each of them with two rack profiles. Return to the table of contents</a>

Design of openings

The door should be marked at the stage of assembling the frame. Any partition cannot do without an opening, since otherwise it will not be possible to get into the new room. Installation diagram of a plasterboard partition. Installation features:

Installation diagram of a plasterboard partition. Installation features:

The width of the opening must correspond to the sizefuture door + 8 cm. The additional distance may be more, it all depends on the configuration. The reserve is necessary for installing the door frame, trim and jambs. Return to the table of contents</a>

Arch decoration

If you don't want to install a door, you canmake a partition with an empty opening or assemble an arch. In this case, instead of a crossbar, an arched structure will be used, which is also assembled from a profile. Wedges are cut along its edges and the metal is bent to the desired radius. You can make a partition from plasterboard with windows or decorate it with shelves. This step will refresh the interior, make it more original. Windows are decorated using the same technology as doors. The size is regulated by horizontal profiles. Types of profiles for plasterboard installation.The only difference is that when decorating a window, 2 crossbars will be used: along the lower and upper borders. This way, you can make a partition with windows 60 cm wide and of any convenient height. If you need narrower openings, you can install additional posts on the crossbars and adjust the width. If the opening remains empty, then it is not necessary to reinforce the structure. If glazing, stained glass or another decorative element is used, then the presence of bars is required. Do-it-yourself drywall installation is not a difficult task. However, you need to know some subtleties. When attaching gypsum board, you need to leave a small gap at the floor - about 1 cm and at the ceiling - 0.5 cm. The edges of the sheets should lie on the profile and be attached to it. In this case, you need to retreat 10 mm from the edge for factory cutting and 15 mm - for manual cutting. This will avoid crumbling of the material. The sheets should be attached in a checkerboard pattern. Cross-shaped joints should not be allowed, as they are extremely unreliable. When joining sheets by hand cutting, it is advisable to remove the chamfer. Self-tapping screws should be located frequently: every 10-25 cm. On adjacent sheets, they should be offset relative to each other. The caps should be slightly sunk into the plasterboard. The length of the self-tapping screws is selected so that they not only hook onto the profile, but also extend beyond it by approximately 1 cm. Return to contents</a>

Types of profiles for plasterboard installation.The only difference is that when decorating a window, 2 crossbars will be used: along the lower and upper borders. This way, you can make a partition with windows 60 cm wide and of any convenient height. If you need narrower openings, you can install additional posts on the crossbars and adjust the width. If the opening remains empty, then it is not necessary to reinforce the structure. If glazing, stained glass or another decorative element is used, then the presence of bars is required. Do-it-yourself drywall installation is not a difficult task. However, you need to know some subtleties. When attaching gypsum board, you need to leave a small gap at the floor - about 1 cm and at the ceiling - 0.5 cm. The edges of the sheets should lie on the profile and be attached to it. In this case, you need to retreat 10 mm from the edge for factory cutting and 15 mm - for manual cutting. This will avoid crumbling of the material. The sheets should be attached in a checkerboard pattern. Cross-shaped joints should not be allowed, as they are extremely unreliable. When joining sheets by hand cutting, it is advisable to remove the chamfer. Self-tapping screws should be located frequently: every 10-25 cm. On adjacent sheets, they should be offset relative to each other. The caps should be slightly sunk into the plasterboard. The length of the self-tapping screws is selected so that they not only hook onto the profile, but also extend beyond it by approximately 1 cm. Return to contents</a>

Features of cutting gypsum board, work with wiring and soundproofing

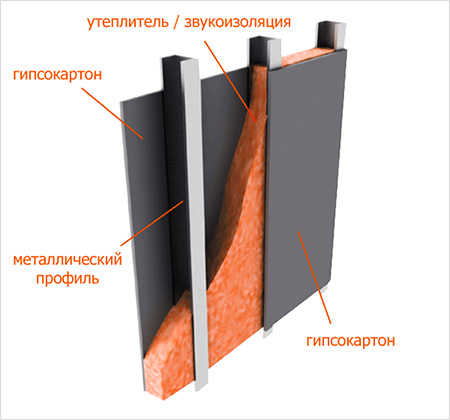

When cutting drywall with your own hands, you canuse a knife with replaceable blades. The sheet is placed on a flat, hard surface (for example, on a table), first a cutting line is drawn on the plasterboard with a pencil, then a knife is drawn along it. A cut is obtained. The plasterboard is shifted to the edge and carefully broken. Then the sheet is turned over, and all operations are repeated on the other side. When pressing, you need to be careful, since now the piece will break off completely. Scheme of a partition using insulation.At the edge after cutting, you need to make a bevel at an angle of 22-23 °. This operation is conveniently carried out using a plasterboard plane. The chamfer is necessary to create a gap that can be sealed with putty. After one side is completely sewn up, you can start installing the wiring and other electrical parts. A hole with a diameter of 3.5 cm is made in the profile, through which the wires pass. All electrical equipment should be hidden in corrugated tubes. This will avoid damaging the wiring. How to make a plasterboard partition quiet? If necessary, a soundproofing layer is laid in it. Mineral wool is used as a material for it. It is convenient to use material that is produced in rolls 60 cm wide, since these strips will just fit into the space between the profiles. You can use a slightly wider material so that it very tightly closes the openings. There is no need to additionally fix the wool. You can not use soundproofing, but then the plasterboard partition will be very resonant, all sounds will pass through it very easily. Return to contents</a>

Scheme of a partition using insulation.At the edge after cutting, you need to make a bevel at an angle of 22-23 °. This operation is conveniently carried out using a plasterboard plane. The chamfer is necessary to create a gap that can be sealed with putty. After one side is completely sewn up, you can start installing the wiring and other electrical parts. A hole with a diameter of 3.5 cm is made in the profile, through which the wires pass. All electrical equipment should be hidden in corrugated tubes. This will avoid damaging the wiring. How to make a plasterboard partition quiet? If necessary, a soundproofing layer is laid in it. Mineral wool is used as a material for it. It is convenient to use material that is produced in rolls 60 cm wide, since these strips will just fit into the space between the profiles. You can use a slightly wider material so that it very tightly closes the openings. There is no need to additionally fix the wool. You can not use soundproofing, but then the plasterboard partition will be very resonant, all sounds will pass through it very easily. Return to contents</a>

Completion of work

After laying the sound insulation and wiring, you cansew up the second side of the partition. Now you can proceed to the final finishing of the walls. How to make a partition perfectly flat? First of all, you need to seal all the joints. First, a layer of putty is applied to the seams, then they are glued with a mounting mesh, and then leveled with putty again on top. The screw heads are also masked with it. After drying, the putty is leveled with a grater and sandpaper. The distance remaining to the floor and ceiling can be sealed with sealant. They act as expansion gaps. After drying and final alignment, the plasterboard partition is ready for finishing with various materials. Making a plasterboard partition is easy and inexpensive. This explains its popularity and widespread use. If you follow the instructions, the wall will be quite reliable, flat and beautiful.