Almost every homeowner inapartment building, dreaming of living in peace and quiet, suffers from noises that come from neighbors. This occurs when soundproofing technology is violated during construction. Sounds from neighboring apartments create a kind of "echo effect" in your room. If you have friendly relations with your neighbors, then it is possible to agree and soundproof the floor in the apartment above. But this does not always work out, so there is another option - do-it-yourself soundproofing of the ceiling and your own apartment. If after a hard day at work you wantto be in silence, then the best way is to soundproof the apartment. It is not at all necessary to invite professionals to do the work, this can significantly increase financial costs. It is quite possible to soundproof the ceiling with your own hands. And first of all, the quality of the work will depend on the soundproofing materials used. Today, the construction market is so vast that you can choose fittings with the best price-quality ratio. Numerous studies show that with the right insulation, the noise level is reduced by 4-5 times. The soundproofing effect is achieved by forming an "air gap" between the ceiling base and the sheets of plasterboard, which is most often used for. It is in this "pocket" that the soundproofing sheets are laid.

If after a hard day at work you wantto be in silence, then the best way is to soundproof the apartment. It is not at all necessary to invite professionals to do the work, this can significantly increase financial costs. It is quite possible to soundproof the ceiling with your own hands. And first of all, the quality of the work will depend on the soundproofing materials used. Today, the construction market is so vast that you can choose fittings with the best price-quality ratio. Numerous studies show that with the right insulation, the noise level is reduced by 4-5 times. The soundproofing effect is achieved by forming an "air gap" between the ceiling base and the sheets of plasterboard, which is most often used for. It is in this "pocket" that the soundproofing sheets are laid.

Types of soundproof materials

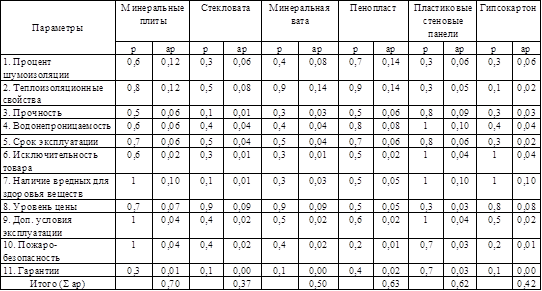

The main function of soundproofing itemsis to create a barrier for sound waves, weaken them or completely eliminate them. The effectiveness of such a barrier will directly depend on the thickness of the fittings used. All insulating items produced today can be divided into several groups: Technical characteristics of soundproofing materials.

Technical characteristics of soundproofing materials.

This tape is produced with an adhesive base, whichsignificantly simplifies its installation. This material is also environmentally friendly and highly elastic, it has an increased service life and high water-repellent properties. Return to contents</a>

Tools for work

Tools for soundproofing the ceiling:level-ruler, water level, tape measure, knife, trowel, spatula, roller, mixer, container for solution. To make soundproofing of the ceiling yourself, you will need the following materials:

Tools for soundproofing the ceiling:level-ruler, water level, tape measure, knife, trowel, spatula, roller, mixer, container for solution. To make soundproofing of the ceiling yourself, you will need the following materials:

- guides;

- glue;

- perforator or drill, screwdriver;

- screws, screws;

- hammer, pliers, hacksaw;

- ladder;

- level, measuring tape;

- spatulas, brushes of different sizes;

- mixture for shpatlevaniya;

- sandpaper;

- suitable material for noise insulation.

Return to Contents</a>

Preparing the ceiling for work

To see existing defectsceiling, it must be cleaned of old paint, whitewash, tiles, etc. First of all, it is necessary to remove the old covering from the ceiling, for some it may even be wallpaper, and for others - just whitewash, it is removed with a spatula to the base. This procedure is carried out in order to see all the defects of the ceiling base, after which all the detected defects should be covered with putty or a special sealant, which will create additional insulation from vibration noise. After this, they proceed to measurements. Measurements are carried out in order to most accurately calculate the volume of materials required for the work. Each material is produced in different sizes, so it is better to immediately think about how the insulation will be located on the ceiling, along or across, it is important to bring the sheets as close to each other as possible in order to exclude "bridges" along which sound can spread. Return to contents</a>

To see existing defectsceiling, it must be cleaned of old paint, whitewash, tiles, etc. First of all, it is necessary to remove the old covering from the ceiling, for some it may even be wallpaper, and for others - just whitewash, it is removed with a spatula to the base. This procedure is carried out in order to see all the defects of the ceiling base, after which all the detected defects should be covered with putty or a special sealant, which will create additional insulation from vibration noise. After this, they proceed to measurements. Measurements are carried out in order to most accurately calculate the volume of materials required for the work. Each material is produced in different sizes, so it is better to immediately think about how the insulation will be located on the ceiling, along or across, it is important to bring the sheets as close to each other as possible in order to exclude "bridges" along which sound can spread. Return to contents</a>

Methods for solving sound propagation problems

There are several ways to make soundproofing. The most common is to make plasterboard sheathing over soundproofing materials. Ceiling soundproofing scheme.The assembly of the frame structure begins with the installation of a guide profile, which is made along the perimeter of the ceiling base with screws or dowels. An indentation equal to the width of the material used is made from the attached profile, and a narrower strip is attached. It will allow additional fixation of the insulation sheet. When the frame installation is complete, you can begin laying the sheet insulator, which is covered on top with either chipboard sheets or, which is much more common, with plasterboard sheets. When the plasterboard sheets are mounted (fastened with screws), the joints are coated with a soundproofing compound (sealant). After the sealant has completely dried, the ceiling is primed, covered with a layer of putty and the final finishing is performed. If the soundproofing layer is supposed to be made of roll material, then it must be mounted before the frame is made. Usually it is made with an adhesive layer. But if it is not there, a special adhesive composition is used, which is diluted according to the instructions. A piece of the required length is cut off from the roll and glued to the adhesive previously applied to the ceiling with a roller. The material is laid with a reserve of about 2-3 cm on the walls. There is no need to overlap the insulation sheets themselves; they should be applied end-to-end. When gluing the insulation sheet, it is necessary to ensure that no air bubbles form. This can also contribute to the conduction of sounds. After installing the sheet insulation, narrow slats are stuffed for attaching the plasterboard sheets. There is another method of how to make soundproofing in your apartment, using a regular stretch ceiling, made of fabric or film. This method of soundproofing is optimal in our apartments with low ceilings. But this procedure cannot be performed without the presence of experienced professionals who are familiar with all the intricacies of installation work. It is unlikely that a beginner in this business will be able to perform stretching without distortions and wrinkles. Regardless of which method of soundproofing the ceiling in your home you prefer, it is necessary to remember that a large part of success depends on the quality of the selected materials, which should be distinguished by their soundproofing parameters. Only then will you be able to enjoy all the delights of peace and comfort that a separate apartment should provide even with noisy neighbors from the upper floors.

Ceiling soundproofing scheme.The assembly of the frame structure begins with the installation of a guide profile, which is made along the perimeter of the ceiling base with screws or dowels. An indentation equal to the width of the material used is made from the attached profile, and a narrower strip is attached. It will allow additional fixation of the insulation sheet. When the frame installation is complete, you can begin laying the sheet insulator, which is covered on top with either chipboard sheets or, which is much more common, with plasterboard sheets. When the plasterboard sheets are mounted (fastened with screws), the joints are coated with a soundproofing compound (sealant). After the sealant has completely dried, the ceiling is primed, covered with a layer of putty and the final finishing is performed. If the soundproofing layer is supposed to be made of roll material, then it must be mounted before the frame is made. Usually it is made with an adhesive layer. But if it is not there, a special adhesive composition is used, which is diluted according to the instructions. A piece of the required length is cut off from the roll and glued to the adhesive previously applied to the ceiling with a roller. The material is laid with a reserve of about 2-3 cm on the walls. There is no need to overlap the insulation sheets themselves; they should be applied end-to-end. When gluing the insulation sheet, it is necessary to ensure that no air bubbles form. This can also contribute to the conduction of sounds. After installing the sheet insulation, narrow slats are stuffed for attaching the plasterboard sheets. There is another method of how to make soundproofing in your apartment, using a regular stretch ceiling, made of fabric or film. This method of soundproofing is optimal in our apartments with low ceilings. But this procedure cannot be performed without the presence of experienced professionals who are familiar with all the intricacies of installation work. It is unlikely that a beginner in this business will be able to perform stretching without distortions and wrinkles. Regardless of which method of soundproofing the ceiling in your home you prefer, it is necessary to remember that a large part of success depends on the quality of the selected materials, which should be distinguished by their soundproofing parameters. Only then will you be able to enjoy all the delights of peace and comfort that a separate apartment should provide even with noisy neighbors from the upper floors.