The use of plastic for interior decoration is becoming widespread. It is used for both walls and ceilings. will solve many problems associated with the quality of the ceiling. Plastic panels have excellentperformance characteristics and attractive appearance. Plastic panels have many positive qualities. They are quite technological and beautiful. You can always choose what you like from a huge assortment. Do-it-yourself suspended plastic ceiling is convenient, fast and practical.

Plastic panels have excellentperformance characteristics and attractive appearance. Plastic panels have many positive qualities. They are quite technological and beautiful. You can always choose what you like from a huge assortment. Do-it-yourself suspended plastic ceiling is convenient, fast and practical.

Features of material selection

The suspended ceiling can be made ofdifferent materials (wood, chipboard, foam, etc.). One of the most common designs is a suspended ceiling made of plastic. Such a surface has a number of advantages: ease of installation, low weight, a large range of colors, low cost. The most important thing is that the plastic ceiling is highly moisture resistant. It can be safely washed with water. Plastic does not deform with changes in humidity and temperature. The most optimal material for plastic ceilings is polyvinyl chloride. It can be used in the form of tiles or panels. Long PVC panels are most widely used. They are made of two types - seamless and relief. Seamless panels have a continuous flat surface, and smooth edges allow you to join the panels together seamlessly. Types of plastic ceiling panels.The relief panel has a groove on one side of the edge, and a longitudinal tenon on the other side. When joining the panels, the tenon enters the groove, and a smooth rectangular groove is formed along the joint. The panel is made in the form of two layers of plastic, between which stiffening ribs are formed, which ensures sufficient mechanical strength. The front surface of the panel is polished (varnished). Standard PVC panels are sold 25 cm wide and 2.7 or 3 m long. Return to contents</a>

Types of plastic ceiling panels.The relief panel has a groove on one side of the edge, and a longitudinal tenon on the other side. When joining the panels, the tenon enters the groove, and a smooth rectangular groove is formed along the joint. The panel is made in the form of two layers of plastic, between which stiffening ribs are formed, which ensures sufficient mechanical strength. The front surface of the panel is polished (varnished). Standard PVC panels are sold 25 cm wide and 2.7 or 3 m long. Return to contents</a>

Choosing a ceiling design

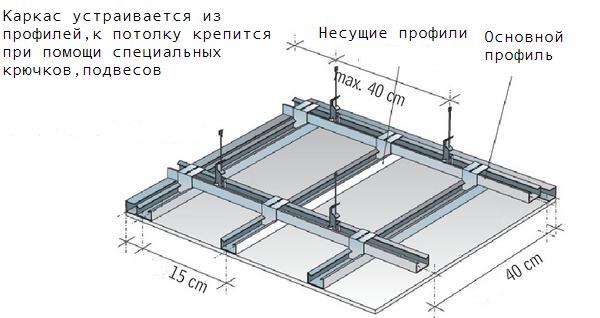

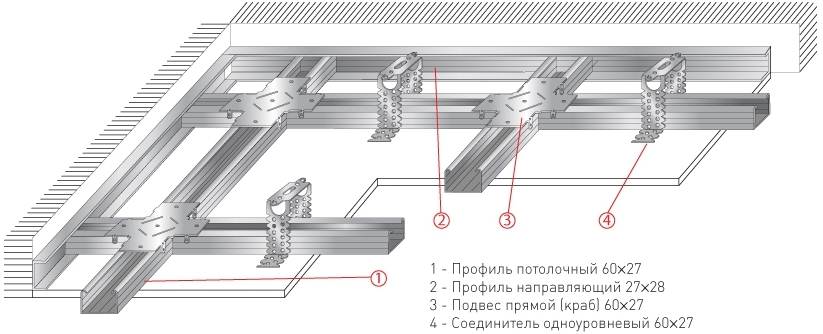

A plastic ceiling can have two mainstructures - suspended and stretch. A stretch plastic ceiling is made of vinyl film. During the installation of such a ceiling, the film must be heated to 70º, which requires the use of special heat guns. Installation of stretch ceilings is usually performed by professionals. For installing a plastic ceiling with your own hands, a suspended structure made of PVC panels is most suitable. A suspended ceiling is a horizontal surface formed from a glossy layer of PVC panels, installed on a metal frame. In this case, the frame is fixed to the wall and ceiling, at a certain distance from the surface of the ceiling. Installation diagram of the frame for a suspended ceiling.The frame is a firmly connected assembly structure in the form of a lattice. The frame is made of metal profiles. The frame is attached to the wall using a U-shaped guide profile. Usually, a PN 28x27 profile is used, 28 mm wide and 27 mm high. The main one is the ceiling profile, which has a C-shape. The PS60x27 profile is used. The lattice structure of the frame is created from this profile. The frame is attached to the ceiling using hangers that ensure the fastening of the profiles to the ceiling. For a cross-shaped connection of the profiles, a "crab" fastener is used. The ceiling profiles are connected to each other using a U-shaped connector 30-40 mm long. When installing PVC panels, the connection along the length is carried out using a plastic connecting profile (H-shaped molding). In addition, when completing the installation of plastic, plastic skirting boards, starting profiles, cornice profiles, corners (external and internal), and clamps can be used to hide the initial gaps. Return to contents</a>

Installation diagram of the frame for a suspended ceiling.The frame is a firmly connected assembly structure in the form of a lattice. The frame is made of metal profiles. The frame is attached to the wall using a U-shaped guide profile. Usually, a PN 28x27 profile is used, 28 mm wide and 27 mm high. The main one is the ceiling profile, which has a C-shape. The PS60x27 profile is used. The lattice structure of the frame is created from this profile. The frame is attached to the ceiling using hangers that ensure the fastening of the profiles to the ceiling. For a cross-shaped connection of the profiles, a "crab" fastener is used. The ceiling profiles are connected to each other using a U-shaped connector 30-40 mm long. When installing PVC panels, the connection along the length is carried out using a plastic connecting profile (H-shaped molding). In addition, when completing the installation of plastic, plastic skirting boards, starting profiles, cornice profiles, corners (external and internal), and clamps can be used to hide the initial gaps. Return to contents</a>

Preparatory work

Scheme of preparing the ceiling for installation of panels.The main ceiling after the installation of the suspended one will be hidden from prying eyes, so there are no increased requirements for its surface. However, it should not be allowed to crumble, and most importantly, it should not have traces of mold or fungus after flooding. The surface of the ceiling should be primed and plastered so that there are no cracks or chips left on it. Areas with mold must first be treated with an antiseptic, for example, a solution of copper sulfate. Return to the table of contents</a>

Scheme of preparing the ceiling for installation of panels.The main ceiling after the installation of the suspended one will be hidden from prying eyes, so there are no increased requirements for its surface. However, it should not be allowed to crumble, and most importantly, it should not have traces of mold or fungus after flooding. The surface of the ceiling should be primed and plastered so that there are no cracks or chips left on it. Areas with mold must first be treated with an antiseptic, for example, a solution of copper sulfate. Return to the table of contents</a>

Surface marking

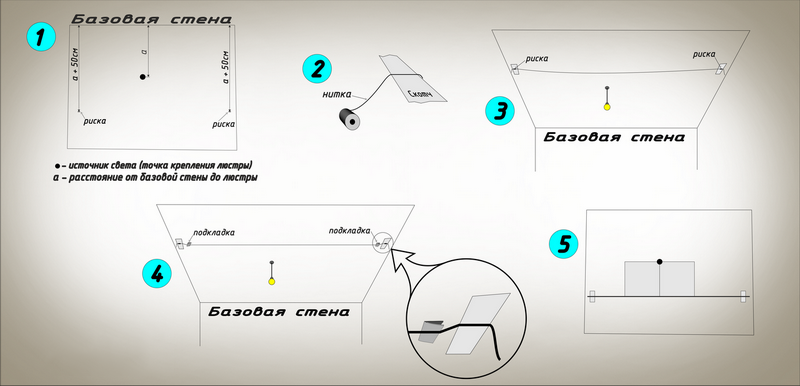

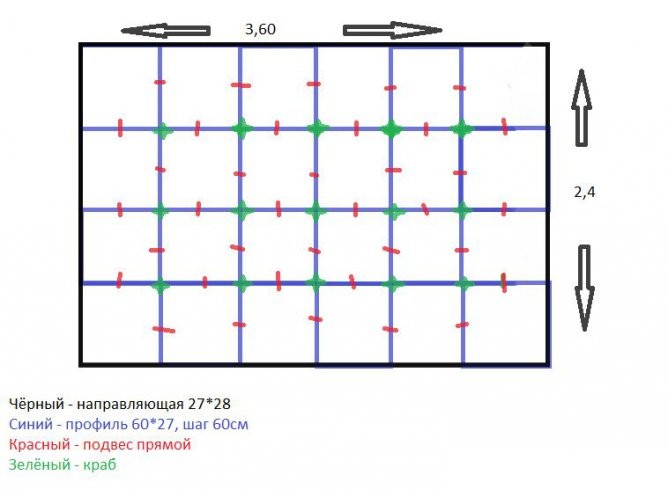

An important preparatory stage that affectson the quality of the entire suspended ceiling, is the marking. First, the true height of the main ceiling is specified in different points of the room. To do this, the height of the wall is measured with a tape measure in at least three points - in the corners and in the center. In the corner with the smallest wall height, a mark is made at the height of the frame profile suspension, that is, at a distance of 5-10 cm from the ceiling. The distance is determined by the need to carry out communications. If it is planned to install built-in (spot) lights or run pipes along the ceiling, then this distance is 8-10 cm; if nothing extra is planned, then 5-6 cm is enough. Then a mark is made on the wall in another corner, but taking into account the actual height of the wall. The suspended ceiling should be parallel to the floor. Through the marks in the corners, a straight line is beaten off using a well-stretched and pre-painted construction cord. The opposite wall is marked in the same way. The lines are connected to each other by marking the other walls. Thus, a line is drawn along the entire perimeter of the room - it is the lower boundary of the frame guide profile. Ceiling layout diagram.The ceiling profiles are marked on the ceiling surface. To do this, parallel lines are first beaten off with a cord in the longitudinal direction. The first and last lines are drawn at a distance of 15-20 cm from the wall. Between them, parallel lines are drawn with a step of 30-40 cm. The lines are marked in the transverse direction in the same way. A grid should be applied to the ceiling, which indicates the location of the central line of the ceiling profiles. The installation of hangers is marked along these lines. The first marks are made at a distance of 25-30 cm from each wall, and all subsequent ones with a step of 50-60 cm. The marks should not coincide with the crosshairs of the lines - they should be shifted by at least 5 cm from the crosshairs. Return to the table of contents</a>

Ceiling layout diagram.The ceiling profiles are marked on the ceiling surface. To do this, parallel lines are first beaten off with a cord in the longitudinal direction. The first and last lines are drawn at a distance of 15-20 cm from the wall. Between them, parallel lines are drawn with a step of 30-40 cm. The lines are marked in the transverse direction in the same way. A grid should be applied to the ceiling, which indicates the location of the central line of the ceiling profiles. The installation of hangers is marked along these lines. The first marks are made at a distance of 25-30 cm from each wall, and all subsequent ones with a step of 50-60 cm. The marks should not coincide with the crosshairs of the lines - they should be shifted by at least 5 cm from the crosshairs. Return to the table of contents</a>

Installing a Guide Profile

Installation of the suspended ceiling frame begins withinstallation of a U-shaped profile on the wall along the marking line. First, holes are drilled in the base of the profiles for fastening to the wall: the first - at a distance of 10-15 cm from the edge, the next ones 30-40 cm from each other. Then it is applied to the wall, and marks are made on it. According to the marks, holes with a diameter of 8 mm are made in the wall with a hammer drill or an electric drill. Plastic dowels are inserted into the holes. The PN profile is fastened to the dowels with screws. In this way, the guides are installed along the entire perimeter of the room. The horizontal installation should be checked with a level. Return to the table of contents</a>

Installation of ceiling profiles and installation of communications

Scheme of the suspended ceiling profile device.First, install the profiles that are directed along the short wall. These profiles should stretch from wall to wall. If it is not possible to select a profile of the required length, then it is joined from two segments. The connection must be reliable and rigid - using a U-shaped standard fastener or a metal strip. The PS profiles are installed in accordance with the markings on the ceiling. The ends are fastened inside the guide profile fixed to the wall. The profiles are located with the base down. The PS profiles in the perpendicular direction are mounted from segments, the length of which is equal to the distance between the installed PS profiles. They are attached using a "crab" fastener. The PS profiles are fixed to the ceiling using hangers. The hangers bend, forming a U-shape. The height of the side post must strictly correspond to the distance from the ceiling to the PS profile. The suspension platform is fastened with screws into the dowels on the main ceiling in the marked places. The suspension legs are attached to the sides of the profile with self-tapping screws. Before attaching the plastic panels, it is necessary to place the entire communication system inside the frame (if necessary). First of all, this concerns electrical wires - for a chandelier or a spotlight system. The wires must be collected in a bundle and placed inside a corrugated hose. The wiring is carried out to the place where the lighting equipment is attached. The wires are carefully attached to the frame profiles. Return to the table of contents</a>

Scheme of the suspended ceiling profile device.First, install the profiles that are directed along the short wall. These profiles should stretch from wall to wall. If it is not possible to select a profile of the required length, then it is joined from two segments. The connection must be reliable and rigid - using a U-shaped standard fastener or a metal strip. The PS profiles are installed in accordance with the markings on the ceiling. The ends are fastened inside the guide profile fixed to the wall. The profiles are located with the base down. The PS profiles in the perpendicular direction are mounted from segments, the length of which is equal to the distance between the installed PS profiles. They are attached using a "crab" fastener. The PS profiles are fixed to the ceiling using hangers. The hangers bend, forming a U-shape. The height of the side post must strictly correspond to the distance from the ceiling to the PS profile. The suspension platform is fastened with screws into the dowels on the main ceiling in the marked places. The suspension legs are attached to the sides of the profile with self-tapping screws. Before attaching the plastic panels, it is necessary to place the entire communication system inside the frame (if necessary). First of all, this concerns electrical wires - for a chandelier or a spotlight system. The wires must be collected in a bundle and placed inside a corrugated hose. The wiring is carried out to the place where the lighting equipment is attached. The wires are carefully attached to the frame profiles. Return to the table of contents</a>

Installation of plastic ceiling coverings

First of all, around the perimeter of the roomguide profiles, a corner strip (starting profile) is attached to install the skirting board. Fastening is carried out with screws at a distance of about 30 cm from each other. A ceiling skirting board is installed on the corner strip, which snaps into the groove. Plastic panels are cut to the required length. If necessary, they are joined with H-molding. Installation begins with the outer corner panel. First, it is placed in the groove of the skirting board, and then fixed to the ceiling frame. Fastening is carried out with self-tapping screws. A hole is pre-drilled in the place where the screw is screwed in. The distance between the screws is 25-30 cm. Each subsequent PVC panel is inserted with its longitudinal tenon on the edge into the groove of the previous panel. Return to the table of contents</a>

Required Tools

Tools for installing a suspended ceiling. For installation from plastic, the following tool is required:

Tools for installing a suspended ceiling. For installation from plastic, the following tool is required:

- perforator;

- electric drill;

- Screwdriver;

- hacksaw for metal;

- scissors for metal;

- vise;

- a hammer;

- knife;

- cord construction;

- level;

- screwdriver;

- pliers;

- jig saw electric;

- roulette;

- line meter.

Suspended ceiling made of plastic - beautifulsolution to many problems. With its help, the desired interior is created, and all the sins of the main ceiling are hidden. Modern PVC panels allow you to install it yourself.