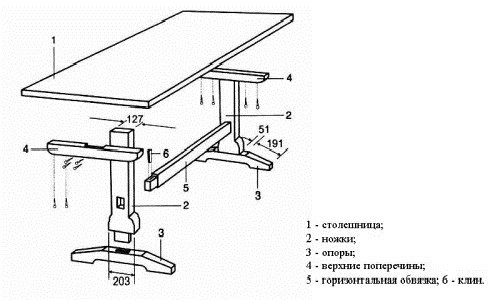

Making a table out of wood with your own hands is not too difficultdifficult, this work will be done with due diligence even by a beginner. If you choose a table with standard parameters, there will be nothing complicated in its manufacture. Before making a table, you need to decide on its appearance and design. Table assembly diagram.

Table assembly diagram.

Materials and Tools

In order to, you will need:

- cant;

- Eurofaner;

- saw;

- grinding machine;

- sandpaper;

- electric drill;

- solvent;

- glue joiner;

- screwdriver;

- self-tapping screws;

- brush;

- varnish;

- work gloves;

- glasses;

- level;

- gon;

- roulette;

- pencil.

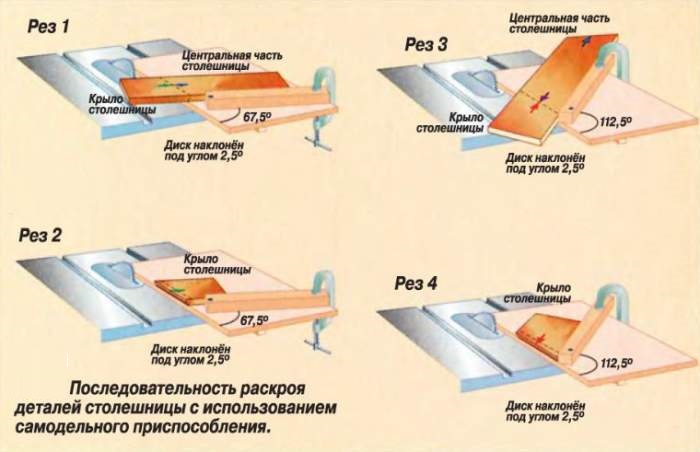

Table top manufacturing diagram.It is best to choose pine or spruce timber, checking the wood for dryness. A product made from poorly dried wood may dry out, crack or lose stability due to a change in size. It is preferable to choose pine or, at worst, spruce, but pine is much easier to process. The texture of pine is more pleasant to look at than spruce. Tables are often made of walnut or oak, but such wood is not available everywhere. If the table is to be made from underdried wood, it must be assembled and left to dry, without varnishing it before this point. Spruce and pine wood have resinous content, which must be removed before work and finishing coatings. This is done using a large amount of solvent or white spirit and a lot of rags. This procedure must be carried out outside living quarters, as the smell will be very strong. It is fire hazardous to carry out such work indoors. Return to contents</a>

Table top manufacturing diagram.It is best to choose pine or spruce timber, checking the wood for dryness. A product made from poorly dried wood may dry out, crack or lose stability due to a change in size. It is preferable to choose pine or, at worst, spruce, but pine is much easier to process. The texture of pine is more pleasant to look at than spruce. Tables are often made of walnut or oak, but such wood is not available everywhere. If the table is to be made from underdried wood, it must be assembled and left to dry, without varnishing it before this point. Spruce and pine wood have resinous content, which must be removed before work and finishing coatings. This is done using a large amount of solvent or white spirit and a lot of rags. This procedure must be carried out outside living quarters, as the smell will be very strong. It is fire hazardous to carry out such work indoors. Return to contents</a>

How to make a table - blanks

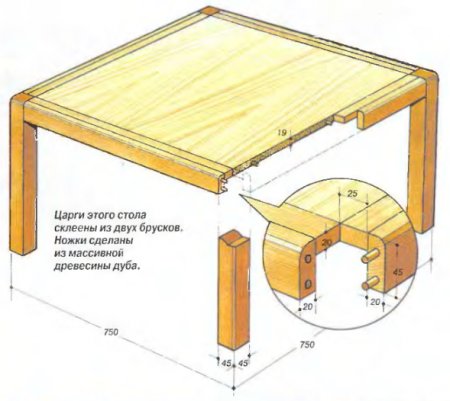

Option for attaching table legs.Legs need to be prepared from the timber, making all 4 pieces identical. Square cubes and crossbars are installed between the legs, giving the structure stability. Without adding them, the legs are very easy to break. Ready-made balusters, often found in hardware stores, can be purchased as legs. They need to be chosen carefully, since all 4 legs of the table must be the same and hold the tabletop level. The tabletop can be round, this option is very good for a dining table. But in order for such a table to fit into the interior, the room must be spacious enough, otherwise the table takes up a lot of space. Oval-shaped tabletops are often used for dining tables, more people can fit at such a table. Oval and round tables seem more harmonious to many, besides, this eliminates the problem of sharp corners if there are small children in the house. Small tables are common in a set with corner kitchen sets. Round and oval tables create an atmosphere of community for those sitting at them.

Option for attaching table legs.Legs need to be prepared from the timber, making all 4 pieces identical. Square cubes and crossbars are installed between the legs, giving the structure stability. Without adding them, the legs are very easy to break. Ready-made balusters, often found in hardware stores, can be purchased as legs. They need to be chosen carefully, since all 4 legs of the table must be the same and hold the tabletop level. The tabletop can be round, this option is very good for a dining table. But in order for such a table to fit into the interior, the room must be spacious enough, otherwise the table takes up a lot of space. Oval-shaped tabletops are often used for dining tables, more people can fit at such a table. Oval and round tables seem more harmonious to many, besides, this eliminates the problem of sharp corners if there are small children in the house. Small tables are common in a set with corner kitchen sets. Round and oval tables create an atmosphere of community for those sitting at them. Coffee table drawing.The most common option is square and rectangular tabletops. Depending on their size and color, they are suitable for any interior and can fit into any room. Extendable tables are very convenient, they take up little space, but if necessary, they can be folded out to a large size and can accommodate many guests. Although these tables are universal, this factor does not suit everyone. In pursuit of individuality, owners make tabletops from a variety of materials, including cuts of thick trees. A table made of any wood is assembled with your own hands from blanks that must be prepared in advance. For their manufacture, a jigsaw or saw is usually used, depending on the preferences of the master. Before sawing off the parts, it is necessary to make accurate calculations and mark the cutting lines using a square and a pencil. Even angles are very important in the manufacture of parts, since without their observance, the entire product will be inconvenient to use. For beginners in carpentry, when processing wood with their own hands, it is recommended to make a cut with a reserve, so that later the curvature can be sanded down without compromising the overall appearance of the structure. When a wooden table has all the parts, before assembly, each of them is sanded and sanded until completely smooth. All recesses with cracks, if they appeared in the process, need to be putty. The process as a result of which it is planned to make a table, can be divided into two categories: preliminary processing and finishing. Return to the table of contents</a>

Coffee table drawing.The most common option is square and rectangular tabletops. Depending on their size and color, they are suitable for any interior and can fit into any room. Extendable tables are very convenient, they take up little space, but if necessary, they can be folded out to a large size and can accommodate many guests. Although these tables are universal, this factor does not suit everyone. In pursuit of individuality, owners make tabletops from a variety of materials, including cuts of thick trees. A table made of any wood is assembled with your own hands from blanks that must be prepared in advance. For their manufacture, a jigsaw or saw is usually used, depending on the preferences of the master. Before sawing off the parts, it is necessary to make accurate calculations and mark the cutting lines using a square and a pencil. Even angles are very important in the manufacture of parts, since without their observance, the entire product will be inconvenient to use. For beginners in carpentry, when processing wood with their own hands, it is recommended to make a cut with a reserve, so that later the curvature can be sanded down without compromising the overall appearance of the structure. When a wooden table has all the parts, before assembly, each of them is sanded and sanded until completely smooth. All recesses with cracks, if they appeared in the process, need to be putty. The process as a result of which it is planned to make a table, can be divided into two categories: preliminary processing and finishing. Return to the table of contents</a>

DIY table - assembly of parts

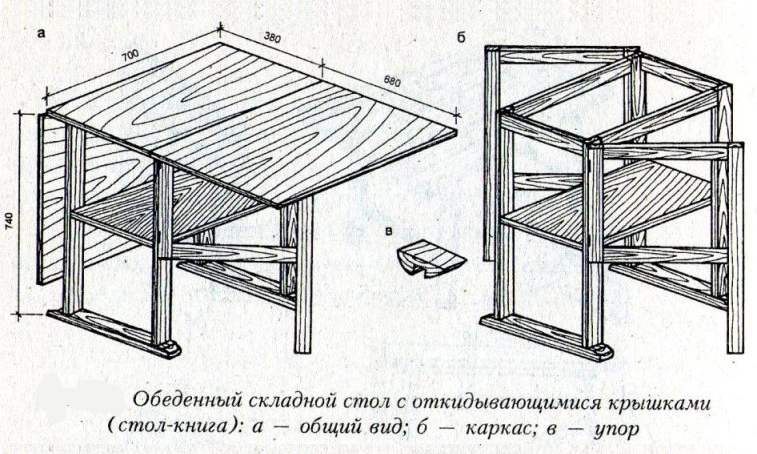

Diagram of a folding book table.Assembling the finished parts is the simplest and at the same time the most responsible process for those who have decided to make a wooden table. Craftsmen recommend painting and varnishing the blanks before assembly, so as not to leave the internal parts uncoated. But before this, it is imperative to conduct a trial assembly to correct any inaccuracies that may be found. It is recommended to varnish or paint only after this. After the first layer of varnish, the surface usually becomes very rough, since all the wood fibers stand on end. Therefore, after the first layer dries, it is necessary to carefully sand all surfaces again and varnish again. Sometimes this needs to be done twice. The parts are most conveniently secured with self-tapping screws or Euro screws. In order for the wooden table to be indistinguishable from the factory version, it is recommended to cover the fastener heads with special plugs. They are sold in furniture stores along with other fittings, and they can be individually selected to match any shade of wood. The legs are attached to the tabletop from the inside using self-tapping screws. The base box achieves its required strength due to the fact that the wood on the long parts has a horizontal structure. Return to the table of contents</a>

Diagram of a folding book table.Assembling the finished parts is the simplest and at the same time the most responsible process for those who have decided to make a wooden table. Craftsmen recommend painting and varnishing the blanks before assembly, so as not to leave the internal parts uncoated. But before this, it is imperative to conduct a trial assembly to correct any inaccuracies that may be found. It is recommended to varnish or paint only after this. After the first layer of varnish, the surface usually becomes very rough, since all the wood fibers stand on end. Therefore, after the first layer dries, it is necessary to carefully sand all surfaces again and varnish again. Sometimes this needs to be done twice. The parts are most conveniently secured with self-tapping screws or Euro screws. In order for the wooden table to be indistinguishable from the factory version, it is recommended to cover the fastener heads with special plugs. They are sold in furniture stores along with other fittings, and they can be individually selected to match any shade of wood. The legs are attached to the tabletop from the inside using self-tapping screws. The base box achieves its required strength due to the fact that the wood on the long parts has a horizontal structure. Return to the table of contents</a>

How to make a table with your own hands - finishing coatings

Finishing the homemade furniture is necessaryby applying a finishing coating to its surface. As a rule, this is varnish, stain or paint. All these options do their job very well, and which one to choose, everyone must decide for themselves. Alkyd-based varnishes have a good coating, but at the same time, a beginner may have problems with their application; if the rules are not followed, the coating becomes bumpy, opaque and has many bubbles. If the question is how to make a table quickly and without unpleasant odors, water-based varnishes for baths and saunas are best suited. Any paints are suitable for wood, you can paint with acrylic or oil, the main thing is that the coating is ultimately not afraid of water.</ ul>