When you come to the kitchen, the first thing you do ispay attention to the table and chairs. Without them it would be uncomfortable and unwelcoming. Of course, you can buy a complete set in the store, which includes several chairs and one table. However, this is not cheap. Therefore, you can try to make tables and chairs with your own hands. Making a table and chairs with your own hands is not as complicated a process as it seems at first glance, and in addition, it will help you save on purchasing new furniture.

Making a table and chairs with your own hands is not as complicated a process as it seems at first glance, and in addition, it will help you save on purchasing new furniture.

How to start a workflow

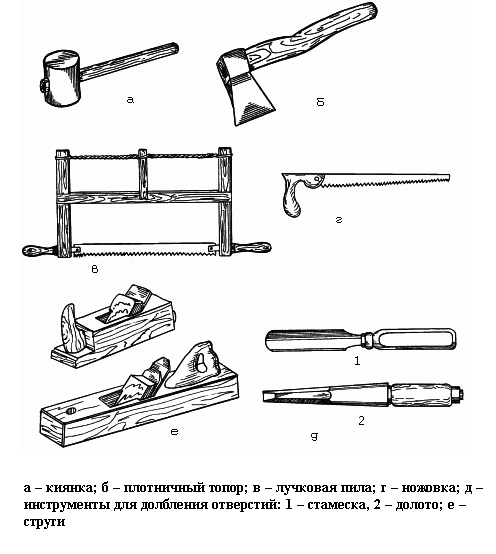

To do this work you will need:

- jointer;

- electric jigsaw;

- chisel;

- drill;

- screwdriver;

- self-tapping screws;

- crafting table.

- glue joiner.

To make tables and chairs, you need to havewell-dried lumber. The moisture content of the wood should not exceed 10%. Otherwise, the work will be unreliable and of poor quality. In most cases, tables are made in several types:

- rectangular;

- round;

- square.

Tools for making tables and chairs.In the kitchen, a table and chairs of the same set are most often installed. The most labor-intensive process when making a table is considered to be the creation of the table top. It consists of two parts:

Tools for making tables and chairs.In the kitchen, a table and chairs of the same set are most often installed. The most labor-intensive process when making a table is considered to be the creation of the table top. It consists of two parts:

- countertops;

- podstolya.

To make the table, you will need edged tongue and groove boards with dimensions of 50x100x3000 mm. You will need 20 m for assembly. Each board must be flawless. The following are not allowed:

- cracks;

- deformation;

- inaccuracies;

- knots.

I would especially like to say something about the knots.When you look at them on the cover of a magazine, it seems like everything is beautiful. However, in life, everything is different. When wood is processed manually, then when making a table, many difficulties arise. Each board must be planed with a plane. Marks are applied with a pencil, which show the direction of planing, passing without burrs. The edges of the boards are processed with a jointer. This achieves:

- absence of scuffing;

- straightness;

- perpendicularity.

Return to Contents</a>

Practical recommendations

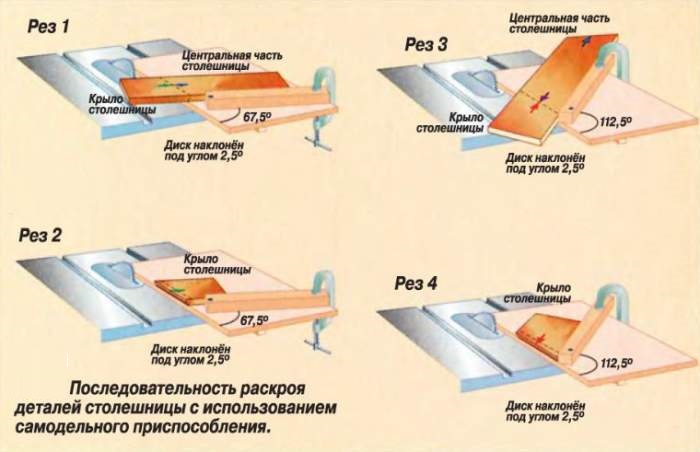

Table top manufacturing diagram.The table top is assembled from several boards, which have a length with a small allowance. The entire set of boards is assembled in several steps, for which wedge clamps are used. Usually their number does not exceed 5 pieces. For clamps, 50 mm bars are taken, fastened with bolts and glue. All slippery surfaces of the clamping wedges must be planed. First, the central block is assembled, consisting of 3 parts. They are all glued together. After that, another plot is glued to each side. PVA is suitable for creating strength and an invisible seam. This glue is mainly used for wooden furniture products. When the blanks are glued, they must be laid so that the non-burring planing is directed in each plot in one direction. The annual rings must alternate. Dowels fixed to the sides of the table with a step of 250 mm will give increased strength to the round table top. When the glue is completely dry, each blank is processed with a jointer. The flatness is controlled by the edge of the ruler. No gaps are allowed. The front side of the tabletop should be the one with the least defects. For work, the table is covered with a sheet of hardboard. The geometric center is on the underside of the tabletop. The circle is marked. To obtain a round workpiece, you will need a jigsaw. A tabletop of the required diameter is made. The jigsaw should be located on the underside of the workpiece. To saw off the chamfer, the jigsaw is set at an angle of 45 °. If the table should have a semicircular edge on the tabletop, the chamfer is removed from the outside. Now the hardboard is no longer needed. It can be removed. The cut area is covered with PVA. This will prevent the wood from chipping. The structure must be well dried.

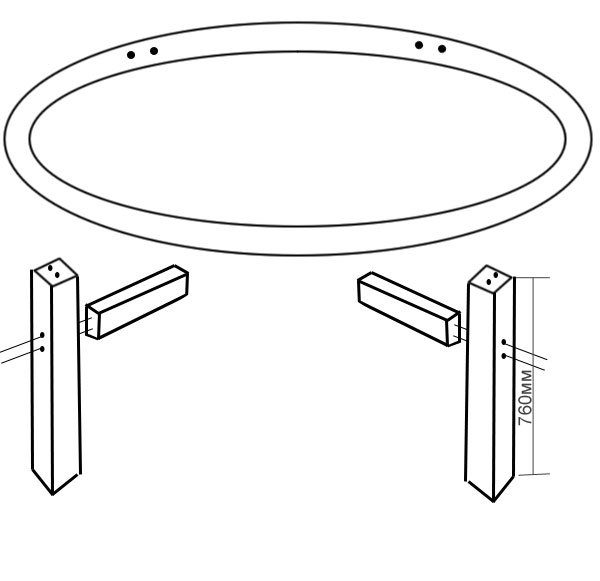

Table top manufacturing diagram.The table top is assembled from several boards, which have a length with a small allowance. The entire set of boards is assembled in several steps, for which wedge clamps are used. Usually their number does not exceed 5 pieces. For clamps, 50 mm bars are taken, fastened with bolts and glue. All slippery surfaces of the clamping wedges must be planed. First, the central block is assembled, consisting of 3 parts. They are all glued together. After that, another plot is glued to each side. PVA is suitable for creating strength and an invisible seam. This glue is mainly used for wooden furniture products. When the blanks are glued, they must be laid so that the non-burring planing is directed in each plot in one direction. The annual rings must alternate. Dowels fixed to the sides of the table with a step of 250 mm will give increased strength to the round table top. When the glue is completely dry, each blank is processed with a jointer. The flatness is controlled by the edge of the ruler. No gaps are allowed. The front side of the tabletop should be the one with the least defects. For work, the table is covered with a sheet of hardboard. The geometric center is on the underside of the tabletop. The circle is marked. To obtain a round workpiece, you will need a jigsaw. A tabletop of the required diameter is made. The jigsaw should be located on the underside of the workpiece. To saw off the chamfer, the jigsaw is set at an angle of 45 °. If the table should have a semicircular edge on the tabletop, the chamfer is removed from the outside. Now the hardboard is no longer needed. It can be removed. The cut area is covered with PVA. This will prevent the wood from chipping. The structure must be well dried. Assembly diagram of table parts.The edges are planed with a well-sharpened plane. A template is used for the operation, which allows you to control the shape. The final finishing is done with sandpaper. The tabletop is sanded until a smooth surface is obtained. An electric grinder that processes wooden surfaces shows excellent results. To ensure the stability of the table, a support cross is made. Hardwood serves as the material for it. The most commonly used:

Assembly diagram of table parts.The edges are planed with a well-sharpened plane. A template is used for the operation, which allows you to control the shape. The final finishing is done with sandpaper. The tabletop is sanded until a smooth surface is obtained. An electric grinder that processes wooden surfaces shows excellent results. To ensure the stability of the table, a support cross is made. Hardwood serves as the material for it. The most commonly used:

- oak;

- Birch.

For the crossbar, take two boards with the following dimensions40x100x1000 mm. They undergo finishing, then are connected in the center with glue and screws. The table cannot exist without legs. For this, birch cuttings intended for a shovel are taken, the size of which is not less than 50 mm. They are carefully cleaned with sandpaper. Various balusters are suitable for legs. All parts are fastened with clamps so that the geometric dimensions match. The fibers of the table top should be perpendicular to the fibers of the base. To install the legs, the crosspiece is pre-drilled to the desired size. The table top is glued to the base, screwed in with screws, while simultaneously inserting the legs. It is necessary to wait until the glue dries, then the legs are glued to the base. Thus, the parallelism of the base relative to the table top is maintained. Return to the table of contents</a>

We make chairs: features

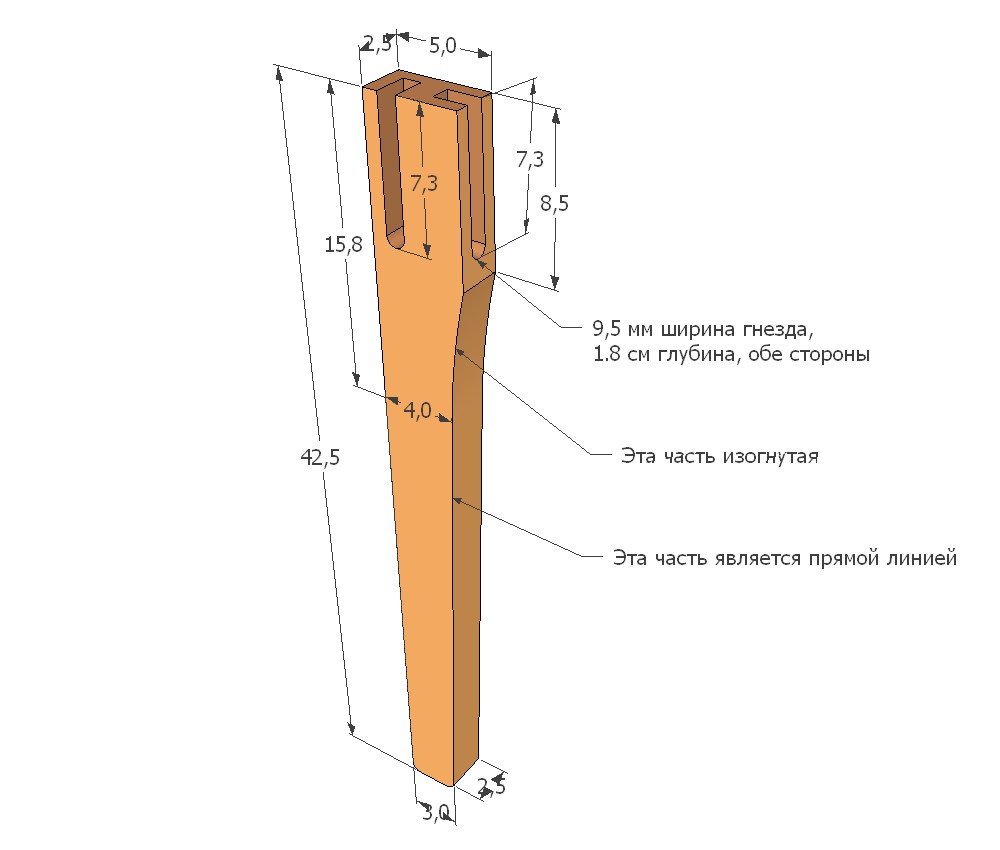

To make tables and chairs, you needprepare the bars. The chair legs can be made from bars measuring 40 x 70 mm. The front legs should have a 30 mm allowance at the attachment points. The crossbars are made from bars measuring 30 x 45 mm. The front legs are equipped with blind sockets for the collets. Chair leg diagram.The front legs are connected with tenons measuring 20 x 50 mm, the back legs with tenons measuring 20 x 68 mm. Each leg should have a groove measuring 15 x 43 mm, where the crossbars will be inserted. To insert the backrest, the back legs are equipped with 20 x 90 mm grooves. The grooves are selected with a chisel after marking. When all the parts are made, the rough assembly of the side of the chair is carried out. The tenons are adjusted. To do this, use a hacksaw to remove excess material from the tenons. Using a mallet, the joint is compacted. To gain skills and experience, it is better to first make one blank. When the rough assembly is carried out, any inaccuracies in the parts made during marking will immediately be revealed. The curved elements of the chair are cut out with a hand-held electric jigsaw, adhering to the dimensions specified in the drawing. The resulting parts are processed with several tools:

Chair leg diagram.The front legs are connected with tenons measuring 20 x 50 mm, the back legs with tenons measuring 20 x 68 mm. Each leg should have a groove measuring 15 x 43 mm, where the crossbars will be inserted. To insert the backrest, the back legs are equipped with 20 x 90 mm grooves. The grooves are selected with a chisel after marking. When all the parts are made, the rough assembly of the side of the chair is carried out. The tenons are adjusted. To do this, use a hacksaw to remove excess material from the tenons. Using a mallet, the joint is compacted. To gain skills and experience, it is better to first make one blank. When the rough assembly is carried out, any inaccuracies in the parts made during marking will immediately be revealed. The curved elements of the chair are cut out with a hand-held electric jigsaw, adhering to the dimensions specified in the drawing. The resulting parts are processed with several tools:

- plane;

- cycle;

- sandpaper.

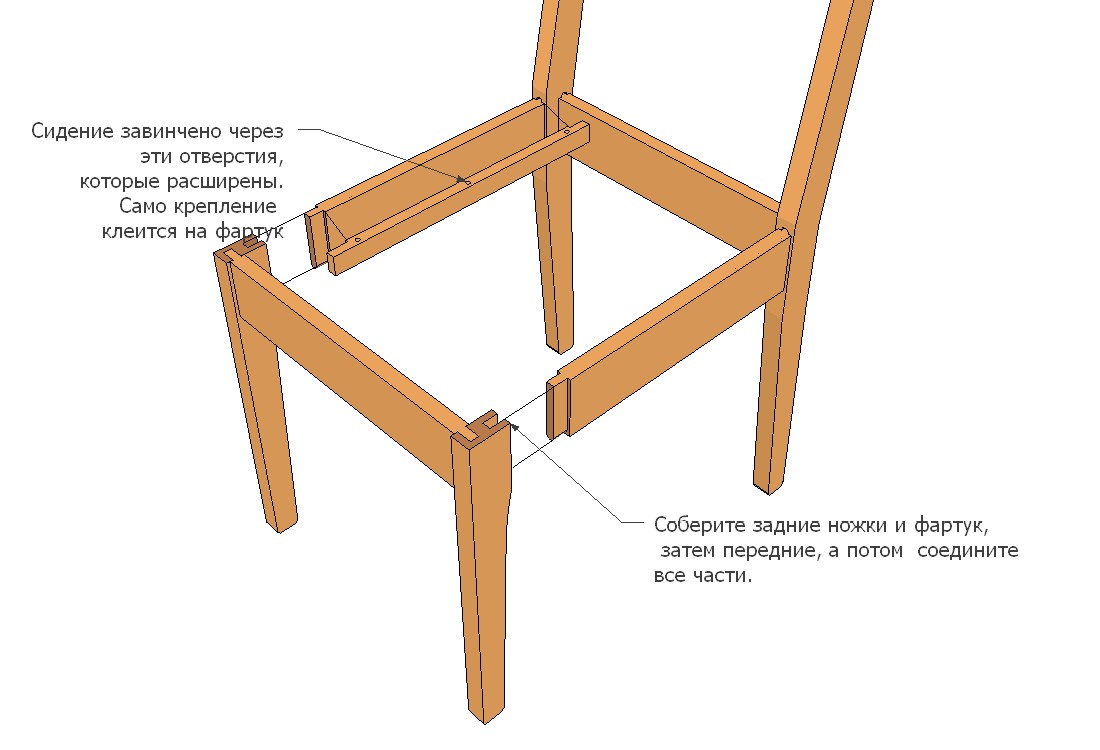

The back is connected to the legs and is finished byadjustment of the joint of the crossbars and tenons. Then the chair assembled for adjustment is disassembled. All allowances are sawed off, the parts are brought to the final round shape. For this, it is advisable to use control templates. A belt sander shows very good results. In order to make the seat of the chair, three sheets of thick plywood are pre-bent according to certain dimensions. The plywood pieces are glued together. Chair assembly diagram.To maintain the bend, the plywood must be coated with ammonia before bending. Then it is placed on its side on the supports and a heavy load is placed on top. When the plywood dries, the bend will be maintained. For sitting, you must have:

Chair assembly diagram.To maintain the bend, the plywood must be coated with ammonia before bending. Then it is placed on its side on the supports and a heavy load is placed on top. When the plywood dries, the bend will be maintained. For sitting, you must have:

- foam rubber;

- batting;

- furniture fabric.

Foam rubber is placed on the prepared seatbatting, then it is covered with fabric. The fabric is attached from below with a construction stapler. The sides of the wooden chair are inserted into the prepared wedge clamps, then everything is glued together. After this, the longitudinal side rails and support bars are connected. They are glued together, but to achieve greater reliability, they are screwed on with screws. Each front side rail is equipped with a recess that exactly matches the shape of the seat. The side rail intended for rear fastening is also connected to a bar that has a similar recess. When everything is assembled, the sides are glued together, and the chair frame is assembled. The final touch will be fastening the seat. The supports are screwed on with screws. Return to contents</a>

Tables and chairs: lacquer work

Technological operation of varnishing suchwooden products consists of applying a varnish coating to furniture items. Tables and chairs are varnished with a spray gun. You can also use an ordinary vacuum cleaner with a special nozzle. The varnish is first dissolved with a thinner. To give the tabletop a mirror appearance, you need to cover its edge with tape. Moreover, it should rise above the plane of the table. Then pour a very thin layer of diluted varnish over the surface. For such work, it is necessary that the tabletop has a strictly horizontal position. To prevent dust from getting in, the coating must be protected with a screen. It must be said that varnishing is the final operation when tables and chairs are made with your own hands. Nothing can be corrected. In this regard, before proceeding with the main varnishing, you need to try this operation on a workpiece. Especially if foreign paints and varnishes are used.