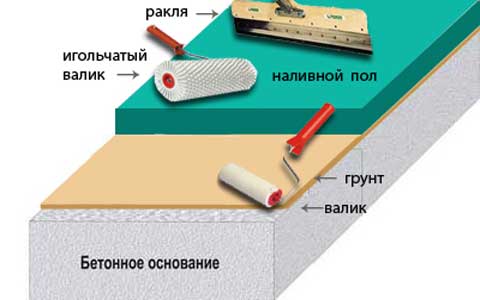

Self-leveling floors usually act asbases for further arrangement of all kinds of finishing coatings. If the technology of pouring the self-leveling floor is observed, the surface will be distinguished by a perfectly flat horizontal plane. Scheme of self-leveling floor installation.

Scheme of self-leveling floor installation.

Preparatory work

If you have to work with a tiled baseor a wooden floor, then you can arrange the self-leveling coating directly on them, but it is recommended to make preparations, which involves dismantling the old coating. To carry out work on pouring the self-leveling floor, you should prepare tools and materials:

- jackhammer;

- roller;

- brush;

- kraskostupy;

- capacity;

- drill;

- putty knife;

- level;

- aeration roller;

- deformation tape;

- primer;

- a mixture of the filler floor;

- mixture for screed;

- sealant.

Tools for self-leveling floors.The technology of pouring a self-leveling floor requires leveling the surface in order to avoid overspending the dry mixture, which can increase the cost of the process. In order to check whether a cement or concrete screed is suitable for pouring, it is necessary to analyze it for the absence of all kinds of irregularities and peeling elements, the latter of which must be removed and treated with a primer or a ready-made mixture for installing the screed. Floor pouring should be carried out exclusively on a clean base, which indicates the need to remove oil and grease stains, as well as traces of paint. The surface can be cleaned with a construction vacuum cleaner. Next, it is necessary to prime the base, which will ensure the most effective adhesion of the topcoat mixture and the base. In the case of a concrete surface, a specially designed primer should be used, while for a cement-sand surface, an ordinary primer should be used. The composition is most conveniently applied with a roller; a brush will allow you to reach hard-to-reach places. If the base is excessively porous, it is permissible to reapply the primer composition, but this should be done only after the first one has completely dried.

Tools for self-leveling floors.The technology of pouring a self-leveling floor requires leveling the surface in order to avoid overspending the dry mixture, which can increase the cost of the process. In order to check whether a cement or concrete screed is suitable for pouring, it is necessary to analyze it for the absence of all kinds of irregularities and peeling elements, the latter of which must be removed and treated with a primer or a ready-made mixture for installing the screed. Floor pouring should be carried out exclusively on a clean base, which indicates the need to remove oil and grease stains, as well as traces of paint. The surface can be cleaned with a construction vacuum cleaner. Next, it is necessary to prime the base, which will ensure the most effective adhesion of the topcoat mixture and the base. In the case of a concrete surface, a specially designed primer should be used, while for a cement-sand surface, an ordinary primer should be used. The composition is most conveniently applied with a roller; a brush will allow you to reach hard-to-reach places. If the base is excessively porous, it is permissible to reapply the primer composition, but this should be done only after the first one has completely dried. Table of compositions for the deviceself-leveling floor. The installation of a self-leveling floor requires the need to provide a temperature-shrinkage joint, which should be located between the poured composition and the wall. Its purpose is to soften the deformation of the screed if the temperature increases or there are movements of the supporting structures of the building. In order to obtain a temperature-shrinkage joint, it is necessary to install a foamed expansion tape, which is glued along the perimeter of the room, including doorways. Return to contents</a>Mixing the working mixture before pouringself-leveling floor with your own hands, you should mix the mixture, while the room temperature should be maintained at least +15 ° C, while the humidity level of the base should be kept at 4%, but not more. If the surface has a higher humidity, then it should be thoroughly dried beforehand. There should be no drafts in the room, so during the work, windows and doors should be kept closed. A temperature slightly above +15 ° C will promote accelerated hardening of the mixture, so such conditions are undesirable. If the temperature is lower, the reaction, on the contrary, will be slow. To prepare the leveling compound, you need to pour the amount of cold water specified in the instructions into the bucket, into which the dry mixture should be poured.

Table of compositions for the deviceself-leveling floor. The installation of a self-leveling floor requires the need to provide a temperature-shrinkage joint, which should be located between the poured composition and the wall. Its purpose is to soften the deformation of the screed if the temperature increases or there are movements of the supporting structures of the building. In order to obtain a temperature-shrinkage joint, it is necessary to install a foamed expansion tape, which is glued along the perimeter of the room, including doorways. Return to contents</a>Mixing the working mixture before pouringself-leveling floor with your own hands, you should mix the mixture, while the room temperature should be maintained at least +15 ° C, while the humidity level of the base should be kept at 4%, but not more. If the surface has a higher humidity, then it should be thoroughly dried beforehand. There should be no drafts in the room, so during the work, windows and doors should be kept closed. A temperature slightly above +15 ° C will promote accelerated hardening of the mixture, so such conditions are undesirable. If the temperature is lower, the reaction, on the contrary, will be slow. To prepare the leveling compound, you need to pour the amount of cold water specified in the instructions into the bucket, into which the dry mixture should be poured. Options for pouring self-leveling floors.To obtain a homogeneous composition, it is necessary to use an electric drill with an attachment. It is not recommended to use hot water, as this will lead to accelerated hardening of the working mixture. After preparation, the composition should not have lumps, and the state should be homogeneous. After preparation, you should immediately begin pouring the self-leveling floor, as after 15-20 minutes the hardening reaction will begin. Return to the table of contents</a>

Options for pouring self-leveling floors.To obtain a homogeneous composition, it is necessary to use an electric drill with an attachment. It is not recommended to use hot water, as this will lead to accelerated hardening of the working mixture. After preparation, the composition should not have lumps, and the state should be homogeneous. After preparation, you should immediately begin pouring the self-leveling floor, as after 15-20 minutes the hardening reaction will begin. Return to the table of contents</a>

Technology of working mixture application

You need to start pouring the floor yourselffrom the far corner. The composition should be poured onto the surface in a thin strip. The composition should be spread in a thin layer over the surface using a regular and special roller. The entire area should be treated with an aeration roller. The composition should fill the voids, after spreading you will get a perfectly flat floor. Piercing will get rid of air bubbles. The surface should be rolled along the wall extremely carefully to prevent splashing onto the walls. After the self-leveling floor mixture has been leveled in the first strip, the second and all subsequent ones should be poured nearby. Distribution should be carried out using the same technology. The leveling composition will set in 8-10 hours, while its use can begin after three days. After you can move along the surface of the self-leveling floors, you should cut the deformation tape using a knife. If voids were noticed, they should be filled with sealant. Return to the table of contents</a>

Installation of a bulk floor on a wooden base

In order that the solution of the filler floor is goodspread, it is necessary to observe the proportions specified in the instructions. The floor can also be poured over the wooden floor, which must be carefully prepared. This stage involves removing layers from the surface, as well as paint and varnish residues. If necessary, it is permissible to use special fluids. Excellent grind the task and grinders. After the surface can be cleaned from the paint, the floor must be treated with coarse-grained emery, which will give a base with a maximum roughness for better adhesion. Then the surface of the floor can be cleaned of wood dust using a vacuum cleaner and perform a wet cleaning. The next step is to proceed to pouring the surface with the working mixture. Arrangement of bulk floors on the wooden floor is carried out using the same technology as described above, but the use of a wooden floor as a rough surface is not welcomed by specialists. This is due to the fact that the wood has the ability to react extremely sensitively to changes in humidity levels in the room. So, if the humidity rises, the material expands. This indicates that the wood is a very mobile base, which is undesirable, since this can lead to the destruction of the floor and the entire floor covering. For this reason, if you are counting on the continued operation of liquid floors, it is preferable to work harder to remove the wooden floor. After this, it is recommended to equip the concrete base on the black overlap, and only then to proceed to leveling the self-leveling mixture. Back to contents</a>

In order that the solution of the filler floor is goodspread, it is necessary to observe the proportions specified in the instructions. The floor can also be poured over the wooden floor, which must be carefully prepared. This stage involves removing layers from the surface, as well as paint and varnish residues. If necessary, it is permissible to use special fluids. Excellent grind the task and grinders. After the surface can be cleaned from the paint, the floor must be treated with coarse-grained emery, which will give a base with a maximum roughness for better adhesion. Then the surface of the floor can be cleaned of wood dust using a vacuum cleaner and perform a wet cleaning. The next step is to proceed to pouring the surface with the working mixture. Arrangement of bulk floors on the wooden floor is carried out using the same technology as described above, but the use of a wooden floor as a rough surface is not welcomed by specialists. This is due to the fact that the wood has the ability to react extremely sensitively to changes in humidity levels in the room. So, if the humidity rises, the material expands. This indicates that the wood is a very mobile base, which is undesirable, since this can lead to the destruction of the floor and the entire floor covering. For this reason, if you are counting on the continued operation of liquid floors, it is preferable to work harder to remove the wooden floor. After this, it is recommended to equip the concrete base on the black overlap, and only then to proceed to leveling the self-leveling mixture. Back to contents</a>

Arrangement of floor tiles

If there is a floor that has a covering made ofceramic or stone tiles, it also needs to be prepared. Initially, the base needs to be checked for strength and the absence of peeling products. If moving elements were noticed, they should be removed, the base should be cleaned of glue, and the places should be sealed with any composition prepared on a cement base. The entire surface of the tile should be degreased using an organic solvent. The next step is to prepare a primer designed for working with smooth bases. The surface is treated with the resulting composition. If necessary, the mixture can be applied in two layers. The installation of the self-leveling floor should be carried out according to the above scheme, however, it is recommended to fill large areas in parts and in a checkerboard pattern. It is recommended to use the polyurethane mixture only with a break of 12 hours after treating the surface with a primer. In the case of self-leveling floors prepared on epoxy resins, this period should be increased to 18 hours. Pouring the finishing layer, if provided for by the work plan, must be done 4 days after the arrangement of the base. This layer should be several millimeters thick, while the pouring method remains the same. The finishing surface is decorated, then the finishing floor is varnished. After pouring, the room temperature should be maintained within +15° C for another two days. There is no need to moisten the self-leveling floors during this process.