One of the most popular floor coveringsToday, laminate flooring is considered to be made of recycled wood covered with polymer films. It can imitate any surface, has good performance characteristics and is relatively inexpensive. It is simple, even a novice craftsman can handle it. Let's consider it in more detail. Laminate design diagram.

Laminate design diagram.

Preparing the base of the floor before laying the laminate

The process of laying laminate consists of 2 stages: preparatory and main. The preparatory stage includes the following activities:

- preparation of the floor;

- selection of tools and materials needed for this.

One of the main conditions for proper installationlaminate should be considered a flat surface of the base base. Differences in the base surface are allowed for every 2 m - only 1 mm. The technology of laying laminate allows as a base base:

- wooden floors;

- cement strainer.

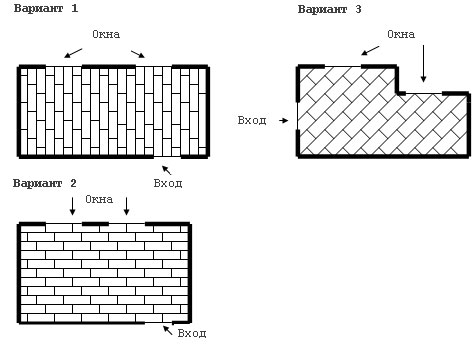

Laminate flooring installation options.Before carrying out the main work, wooden floors should be checked for damage and mold. If necessary, replace old, rotten floorboards. This may require:

Laminate flooring installation options.Before carrying out the main work, wooden floors should be checked for damage and mold. If necessary, replace old, rotten floorboards. This may require:

- a hammer;

- nails;

- new floorboards.

The wooden floor should not sag or wobble,otherwise the laminate flooring will become unusable. In this case, the floor will require complete disassembly and replacement of the boards. A good base for a laminate floor is a smooth cement screed. You can make it yourself from a cement-sand or concrete mortar. To do this, you should prepare:

- solution;

- lighthouses;

- measuring instruments: building level, measuring tape, marker;

- rule;

- grater for the floor.

To make a cement screed, first, beacons are set up according to the measurements and marks made. The height of the screed is chosen arbitrarily. After that, a solution is made for it. Scheme of laying laminate using adhesive method.It can be either concrete or cement-sand. To obtain concrete mortar, take 1 part of grade 400 cement and 7 parts of crushed stone screenings; for cement-sand mortar, take 4 parts of sand and 1 part of cement. After setting the beacons, the floor is filled with mortar and leveled with a rule. The next day, the resulting surface of the new base is cleaned with a float and left to dry completely for about a week. The correct technology for laying laminate with small differences in the base of the floor allows for its leveling with special ready-made mixtures. When using them, the order of work is as follows:

Scheme of laying laminate using adhesive method.It can be either concrete or cement-sand. To obtain concrete mortar, take 1 part of grade 400 cement and 7 parts of crushed stone screenings; for cement-sand mortar, take 4 parts of sand and 1 part of cement. After setting the beacons, the floor is filled with mortar and leveled with a rule. The next day, the resulting surface of the new base is cleaned with a float and left to dry completely for about a week. The correct technology for laying laminate with small differences in the base of the floor allows for its leveling with special ready-made mixtures. When using them, the order of work is as follows:

- dilution of the mixture with water, according to the enclosed instructions;

- Determination of the height of the level of filling the floor;

- smooth distribution of the mixture over the entire surface with a spatula;

- removal of air by a needle roller;

- left to dry, for about 3 days.

After this, you can proceed to the main types of work on laying laminate. Return to the table of contents</a>

Selection and laying of the substrate

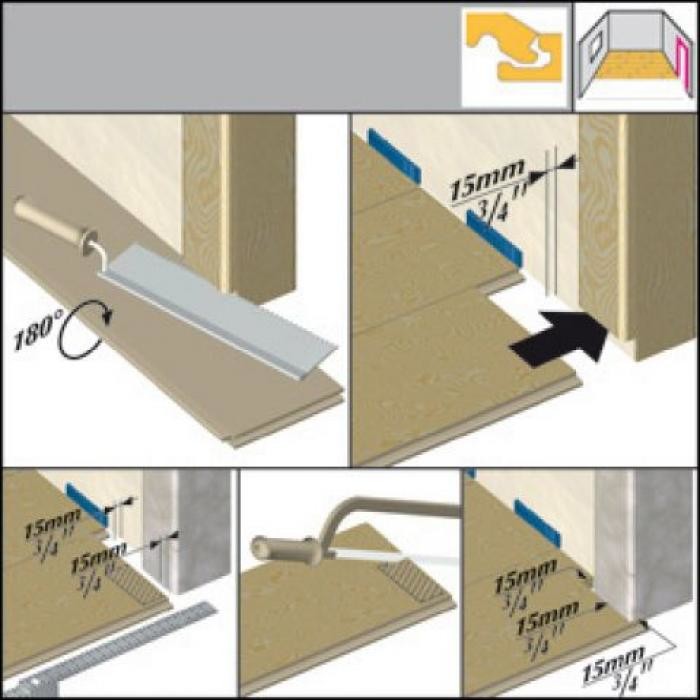

Scheme of laying laminate near doorways.The next important stage of work, taking into account , is the selection and installation of the substrate. It is a special tile or roll material that performs a number of important functions during the process of laying the laminate:

Scheme of laying laminate near doorways.The next important stage of work, taking into account , is the selection and installation of the substrate. It is a special tile or roll material that performs a number of important functions during the process of laying the laminate:

- damping;

- soundproof;

- heat-insulating.

The substrate can be made of various materialsmaterials: natural or polymer. The most valuable is the underlay made of natural cork, made from tree bark. This is a high-quality and environmentally friendly material. But the price of a cork underlay is significantly higher than that of polymer analogues. The thickness of the underlay can vary from 2 to 20 (mm). The thicker its layer, the higher the sound and heat insulation qualities of the floor. In any case, the underlay must be laid in one row, otherwise the laminate may be damaged later. To lay the underlay according to all the rules, you must prepare in advance:

- substrate in the form of plates or a roll (optional);

- building scotch tape or painting tape.

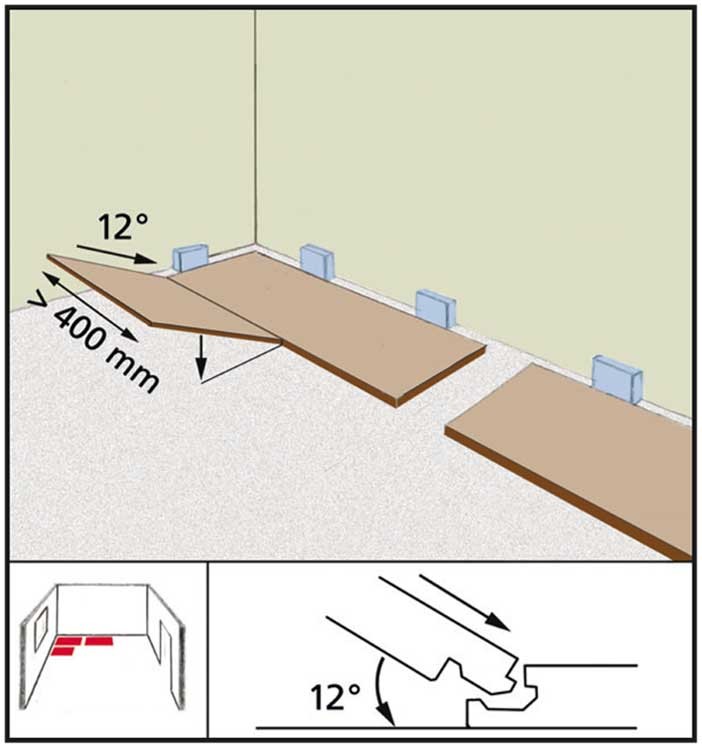

The material is laid on the floor, starting from the windowtowards the entrance door. The underlayment boards or strips should be butt-joined together and secured with construction tape or masking tape. Return to Contents</a>

The process of direct laminate laying

To carry out the basic work on laying the specified floor covering, you will need:

- laminate;

- plinth;

- jigsaw (or hacksaw);

- wedges;

- rubber hammer.

Before carrying out the main work, the main ones should be considered, these include:

- traditional;

- diagonal.

The essence of the traditional method of laying laminateconsists in the perpendicular arrangement of its strips, relative to the window and along the walls of the room. Based on the traditional technology of laying laminate, as a result, you can get a visually smooth and uniform floor surface, without visible joints between its strips. The diagonal method of laying laminate consists in arranging its strips at an angle of 45 degrees relative to the wall in which the window is located. In this case, work begins from the corner, next to the window, gradually moving to the opposite corner, next to the entrance door. It should be noted that with the diagonal method of laying laminate, more material will be required than with the traditional method. Now we should consider the direct mechanism of laying the material. Laminated panels with special locks are easily joined together and fastened. It is important to know that laminated floors must be laid without reaching the wall by about 1.5 cm. This must be done to prevent damage to the floor when the humidity and temperature conditions in the room change. To achieve this goal, you need to use pre-prepared wedges. Following the above rules, lay the first strip of laminate. The next panel is installed starting from the middle of the first one, so that a checkerboard pattern is obtained. Laminated panels are fastened to each other at an angle of 45 degrees, with the groove of one inserted into the tenon of the other, until a characteristic click is heard. If the panel is not tightly seated and a small gap is formed, it is necessary to lightly tap it with a rubber hammer. The panel will fall into place. If necessary, you can trim the panels with a jigsaw. After installing the last panel of laminate, a plinth is installed along the perimeter of the room, which closes the resulting gap to the walls. Thus, knowing what the main stages of work consist of laminate laying technology, even a novice master can cope with it without much difficulty.</ ul>