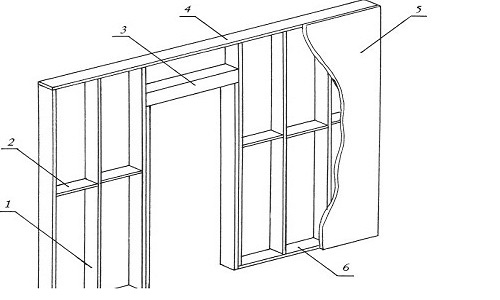

Redistribute the interior space betweenrooms using traditional materials is not at all easy. You need to have special skills and a reserve of time. Meanwhile, everyone can do it. If the future partition is planned with a doorway, the process will not be too complicated. Diagram of a plasterboard partition with a doorway: 1 – vertical beam, 2 – horizontal strut, 3 – door beam, 4 – ceiling beam, 5 – plasterboard, 6 – floor beam.

Diagram of a plasterboard partition with a doorway: 1 – vertical beam, 2 – horizontal strut, 3 – door beam, 4 – ceiling beam, 5 – plasterboard, 6 – floor beam.

Tools and materials

Before making a wall with plasterboard sheathing, you need to prepare everything you need to perform the work. List of tools: Tools for working with plasterboard.

Tools for working with plasterboard.

- perforator;

- level, plumb bob (better laser osepostroitel or level);

- a marking cord;

- marker;

- roulette;

- scissors for metal;

- prosector;

- Screwdriver;

- a hammer;

- knife;

- gypsum plasterboard hacksaw;

- slabs on plasterboard;

- a hacksaw on wood;

- cushion with cuvette;

- drill with a mixer;

- spatulas;

- grinding grid holder.

List of materials:

- galvanized profiles;

- wooden bars;

- dowels "quick installation";

- self-tapping screws;

- a heater (noise isolation);

- soundproof tape;

- drywall;

- primer;

- putty;

- grinding mesh;

- ribbon-serpyanka.

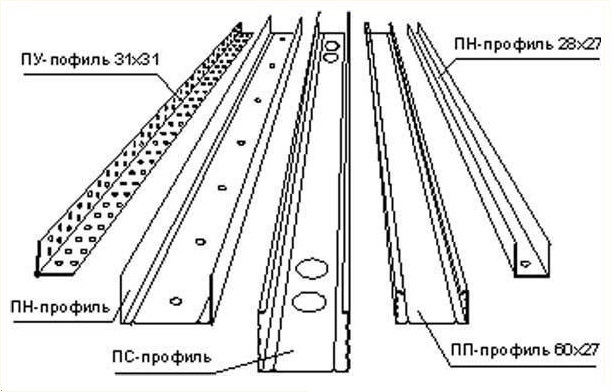

To install partitions, 2-piece profiles are needed.types. UW profiles are used as starting ones. These are U-shaped elements with straight edges. The width of the base varies from 50 to 150 mm with a step of 25 mm. The height of the shelves is 40 mm. The thickness of the galvanized steel used for the production of high-quality profiles is from 0.6 mm. The device of a double-leaf sliding doorPartitions: a - general view, b, c - partition structure units: 1 - plywood, 2 - filler, 3 - bar, 4, 5 - joints of two door panels. The steel used to make the CW rack profiles should have the same thickness. They also have a U-shape, but the edges are bent to increase rigidity. Each UW width corresponds to the same CW rating. In fact, the CW is 1.2 mm narrower to fit between the shelves of the starting one. The height of the shelves of the rack elements is 50 mm. The bars are selected in such a size that they fit tightly inside the CW. That is, for a 50 * 50 mm rack, the cross-section of the bar should be the same. It makes sense to choose wider elements for placing insulating materials or utility lines inside the wall structure. Many do not consider soundproofing tape to be a mandatory accessory, but it can significantly reduce the transmission of vibrations from building structures to the partition. The tape is glued to the outside of all used starting profiles. The need to use insulating materials is determined by the purpose of adjacent rooms and the number of layers of plasterboard in the sheathing. Mineral wool materials are generally used as heat and sound insulation. The use of cellulose insulation (ecowool) is gaining popularity. Return to contents</a>

The device of a double-leaf sliding doorPartitions: a - general view, b, c - partition structure units: 1 - plywood, 2 - filler, 3 - bar, 4, 5 - joints of two door panels. The steel used to make the CW rack profiles should have the same thickness. They also have a U-shape, but the edges are bent to increase rigidity. Each UW width corresponds to the same CW rating. In fact, the CW is 1.2 mm narrower to fit between the shelves of the starting one. The height of the shelves of the rack elements is 50 mm. The bars are selected in such a size that they fit tightly inside the CW. That is, for a 50 * 50 mm rack, the cross-section of the bar should be the same. It makes sense to choose wider elements for placing insulating materials or utility lines inside the wall structure. Many do not consider soundproofing tape to be a mandatory accessory, but it can significantly reduce the transmission of vibrations from building structures to the partition. The tape is glued to the outside of all used starting profiles. The need to use insulating materials is determined by the purpose of adjacent rooms and the number of layers of plasterboard in the sheathing. Mineral wool materials are generally used as heat and sound insulation. The use of cellulose insulation (ecowool) is gaining popularity. Return to contents</a>

Structure of the frame

Door frame installation diagram.To mark the location of the future partition, it is enough to mark 2 points on the floor near the adjacent walls. Using a plumb line or laser devices, they are transferred to the ceiling. Intermediate points are marked along the laser beam or a cord stretched between the extreme ones. By connecting the ends of the lines on the wall and the ceiling, the location of the starting profiles on the wall is determined. Before fixing the UW along the perimeter of the partition, it is necessary to mark the position of the future opening for installing the door block. If the door with the frame is already on the site and its exact width can be measured, the opening is made according to the size of the frame with a margin of 1 cm per side. When installing, the gap is filled with polyurethane foam. Otherwise, you have to start from the nominal width of the door leaf. 10 cm is added to it. The excess gap is covered by the door frame. It can be selected with a width of 5 to 7 cm. The block is not placed close to the adjacent wall. To install a full-fledged frame, it is necessary to retreat at least 5 cm. The height of the opening is selected in a similar way. This is either the block height plus 1 cm or 205 cm. The latter value is determined by the standard door leaf height of 2 m. When taking measurements, the finished floor mark must be known. When installing doors without a threshold, it is necessary to take into account that a gap is left between the floor and the door leaf. In general, it should be 10-15 mm. For some rooms, it is increased.

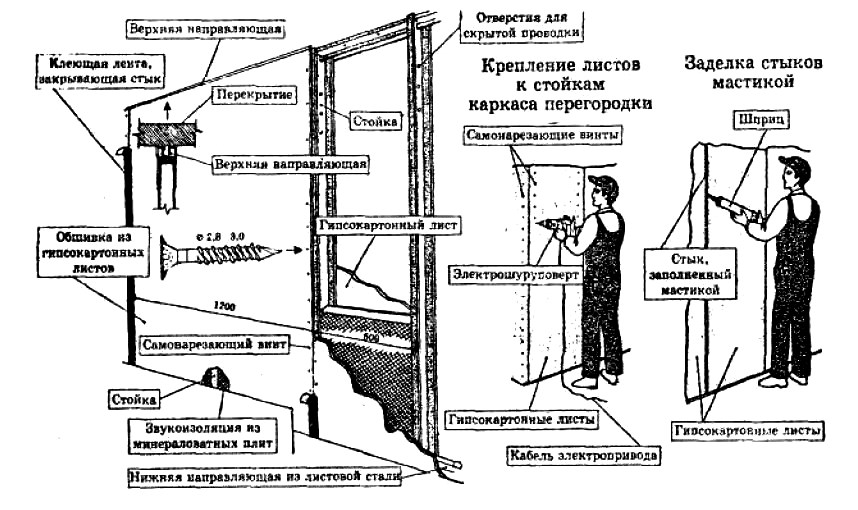

Door frame installation diagram.To mark the location of the future partition, it is enough to mark 2 points on the floor near the adjacent walls. Using a plumb line or laser devices, they are transferred to the ceiling. Intermediate points are marked along the laser beam or a cord stretched between the extreme ones. By connecting the ends of the lines on the wall and the ceiling, the location of the starting profiles on the wall is determined. Before fixing the UW along the perimeter of the partition, it is necessary to mark the position of the future opening for installing the door block. If the door with the frame is already on the site and its exact width can be measured, the opening is made according to the size of the frame with a margin of 1 cm per side. When installing, the gap is filled with polyurethane foam. Otherwise, you have to start from the nominal width of the door leaf. 10 cm is added to it. The excess gap is covered by the door frame. It can be selected with a width of 5 to 7 cm. The block is not placed close to the adjacent wall. To install a full-fledged frame, it is necessary to retreat at least 5 cm. The height of the opening is selected in a similar way. This is either the block height plus 1 cm or 205 cm. The latter value is determined by the standard door leaf height of 2 m. When taking measurements, the finished floor mark must be known. When installing doors without a threshold, it is necessary to take into account that a gap is left between the floor and the door leaf. In general, it should be 10-15 mm. For some rooms, it is increased. Profiles:ceiling - PP, guide - PN, partition, rack - PS. In kitchens and rooms where boilers and gas water heaters are installed, the gap for normal air flow is made about 5 cm high. The lower starting profile is not attached to the opening. Along the rest of the perimeter, it is fixed with dowels or self-tapping screws, depending on the material of the adjacent floor, walls and ceiling. Holes for dowels are drilled through the profile with a hammer drill. You can hammer a dowel nail into the plug with a hammer, or use a hammer drill in impact mode without rotation. The racks are placed vertically in the frame with a pitch of 60 or 40 cm to increase rigidity. When filling the structure with insulating materials, it is more convenient to increase its rigidity by installing paired CW profiles with a pitch of 60 cm. They are placed neck to neck and screwed together with screws every 30-40 cm, forming an I-beam. The UW and CW connection is made without screws using a punch. When using screws, their heads protrude on the front surface of the frame, which prevents the wall from being even due to poor adhesion of the sheets.

Profiles:ceiling - PP, guide - PN, partition, rack - PS. In kitchens and rooms where boilers and gas water heaters are installed, the gap for normal air flow is made about 5 cm high. The lower starting profile is not attached to the opening. Along the rest of the perimeter, it is fixed with dowels or self-tapping screws, depending on the material of the adjacent floor, walls and ceiling. Holes for dowels are drilled through the profile with a hammer drill. You can hammer a dowel nail into the plug with a hammer, or use a hammer drill in impact mode without rotation. The racks are placed vertically in the frame with a pitch of 60 or 40 cm to increase rigidity. When filling the structure with insulating materials, it is more convenient to increase its rigidity by installing paired CW profiles with a pitch of 60 cm. They are placed neck to neck and screwed together with screws every 30-40 cm, forming an I-beam. The UW and CW connection is made without screws using a punch. When using screws, their heads protrude on the front surface of the frame, which prevents the wall from being even due to poor adhesion of the sheets. Scheme of fastening plasterboard to a partition.Horizontal CW are added when it is necessary to increase the height of the sheets at their joints. The joints are staggered. That is, whole sheets are pressed every other one, either to the ceiling or to the floor. With two-layer sheathing, which is performed with a shift of sheets, horizontal inserts are placed mirror-image both from the ceiling and from the floor. CW elements are installed along the perimeter of the opening. A beam of a suitable section is inserted into them and fixed with self-tapping screws from the side of the opening. The presence of a beam significantly increases the rigidity of the structure and facilitates the installation of the frame. Sometimes, to ensure the rigidity of the entire structure, a beam is inserted into each frame post. Return to contents</a>

Scheme of fastening plasterboard to a partition.Horizontal CW are added when it is necessary to increase the height of the sheets at their joints. The joints are staggered. That is, whole sheets are pressed every other one, either to the ceiling or to the floor. With two-layer sheathing, which is performed with a shift of sheets, horizontal inserts are placed mirror-image both from the ceiling and from the floor. CW elements are installed along the perimeter of the opening. A beam of a suitable section is inserted into them and fixed with self-tapping screws from the side of the opening. The presence of a beam significantly increases the rigidity of the structure and facilitates the installation of the frame. Sometimes, to ensure the rigidity of the entire structure, a beam is inserted into each frame post. Return to contents</a>

Skeleton casing

The plasterboard sheets are screwed in place with self-tapping screwsmetal with a countersunk head. For the first layer, use 25 mm long self-tapping screws, for the second - 32 mm. All joints of sheets of both layers must fall on the profiles. With two-layer cladding, the joints of the sheets are shifted relative to each other to the next profile. Scheme of plasterboard joint filling.The step of setting the screws is 20-25 cm. The tightening torque should ensure that the screw head is immersed 1 mm behind the plane of the sheet. The screws are screwed in without tilting, perpendicular to the sheathing. In case of an oblique entry or scrolling, the screw is removed and screwed in next to the indent of about 5 cm. The sheet is fixed along all elements of the frame, both internal and external. Sheets are cut with a knife along the guide. The cardboard is cut on one side, and the sheet is broken on the other. When cutting along a sector, one of the cuts is made with a hacksaw. The part of the sheathing that falls into the opening can be cut off with a hacksaw directly on site. After one-sided sheathing is completed, networks are laid inside the frame and heat and sound insulation is installed. Mineral wool materials are inserted by spacers between the frame posts. Ecowool is applied using an adhesive method. Return to the table of contents</a>

Scheme of plasterboard joint filling.The step of setting the screws is 20-25 cm. The tightening torque should ensure that the screw head is immersed 1 mm behind the plane of the sheet. The screws are screwed in without tilting, perpendicular to the sheathing. In case of an oblique entry or scrolling, the screw is removed and screwed in next to the indent of about 5 cm. The sheet is fixed along all elements of the frame, both internal and external. Sheets are cut with a knife along the guide. The cardboard is cut on one side, and the sheet is broken on the other. When cutting along a sector, one of the cuts is made with a hacksaw. The part of the sheathing that falls into the opening can be cut off with a hacksaw directly on site. After one-sided sheathing is completed, networks are laid inside the frame and heat and sound insulation is installed. Mineral wool materials are inserted by spacers between the frame posts. Ecowool is applied using an adhesive method. Return to the table of contents</a>

Additional instructions

When finishing involvesWhen applying putty, it is necessary to use sheets with a chamfer. When building up sheets vertically and without a factory chamfer at the upper and lower ends, it is done independently. For this, a special plasterboard plane or just a knife is used. The chamfer is removed by 2/3 of the sheet thickness. Before applying putty, the joints are primed. Serpyanka tape is glued along the dried joints and the joint putty is applied with a spatula. After the putty has set, it is sanded with a special mesh. The frame is easily screwed to the frame profiles with bars inserted into the middle with self-tapping screws. Smooth vertical surfaces allow you to quickly and accurately place the frame in the opening. It is enough to focus on the alignment of planes and the uniformity of the gaps. Follow the instructions and the wall with plasterboard sheathing with a door will be strong and neat.</ ul>