Painting walls is still relevant today,despite the fact that modern wallpaper, tiles and all kinds of panels made of different materials have recently appeared on the construction materials market. Moreover, other facing materials also quite often suggest the possibility of subsequent painting, which allows you to get an interior decorated in a completely unique style. The preparation of the walls must be done very carefully,because the quality of further finishing depends on it. Painting involves initial preparation of surfaces, which must be done in several stages.

The preparation of the walls must be done very carefully,because the quality of further finishing depends on it. Painting involves initial preparation of surfaces, which must be done in several stages.

Aligning walls

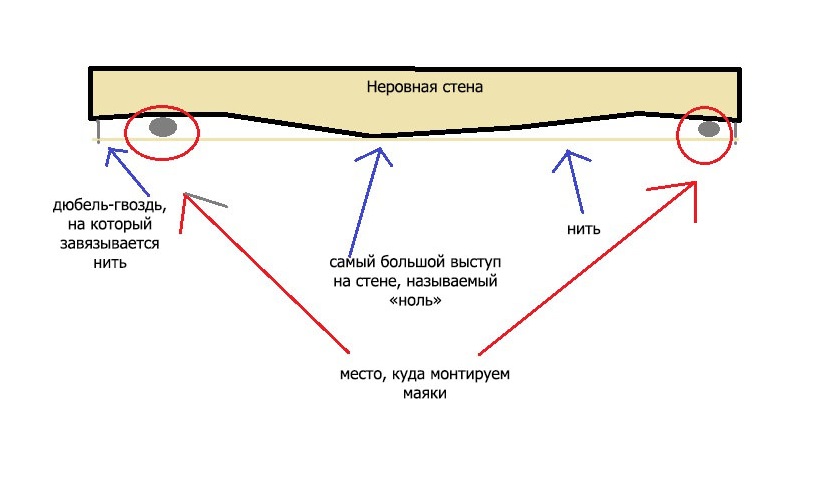

The process involves carrying outinitial alignment and elimination of all possible irregularities. As options, it is permissible to use the method of grinding the existing base, the method of treating the surface with plaster, leveling the walls using sheets of plasterboard. The first method is permissible to take as a basis if the existing layer of plaster or concrete surface has a sufficient margin of safety, while the surface must be intact and have no obvious damage. In this case, it will be necessary to get rid of the old coating and a thin layer of plaster mixture using sandpaper and a grinding bar. It is extremely important to treat old coatings with antiseptic compounds and cover with a primer. Wall alignment diagram.All minor defects in the areas in the form of damage from moisture or fungus must be thoroughly cleaned and decorated with a mixture made on the basis of the composition that was used when plastering. The technology of preparing the walls requires achieving a result in which the differences in level do not exceed 2 mm. Only then can you start applying putty for further painting. In case of significant differences or poor condition of the plaster layer, for example, its partial peeling, it will be necessary to completely replace the plaster; as an alternative solution, you can use gypsum board sheathing of the wall surfaces. The choice of technology for carrying out the work will depend on the skills of the master, as well as the budget allocated for the implementation of the work. In any case, you will have to completely get rid of the old coating, leaving no places that supposedly have a strong layer of mortar. Next, the surface should be leveled using the selected technology. The leveled surfaces are covered with a primer and left until completely dry for a period that can be up to 6 hours. It is preferable to slightly increase the time allocated for the drying stage so that subsequent work can be continued on completely dry walls. Return to Contents</a>

Wall alignment diagram.All minor defects in the areas in the form of damage from moisture or fungus must be thoroughly cleaned and decorated with a mixture made on the basis of the composition that was used when plastering. The technology of preparing the walls requires achieving a result in which the differences in level do not exceed 2 mm. Only then can you start applying putty for further painting. In case of significant differences or poor condition of the plaster layer, for example, its partial peeling, it will be necessary to completely replace the plaster; as an alternative solution, you can use gypsum board sheathing of the wall surfaces. The choice of technology for carrying out the work will depend on the skills of the master, as well as the budget allocated for the implementation of the work. In any case, you will have to completely get rid of the old coating, leaving no places that supposedly have a strong layer of mortar. Next, the surface should be leveled using the selected technology. The leveled surfaces are covered with a primer and left until completely dry for a period that can be up to 6 hours. It is preferable to slightly increase the time allocated for the drying stage so that subsequent work can be continued on completely dry walls. Return to Contents</a>

Treatment of walls with a putty putty

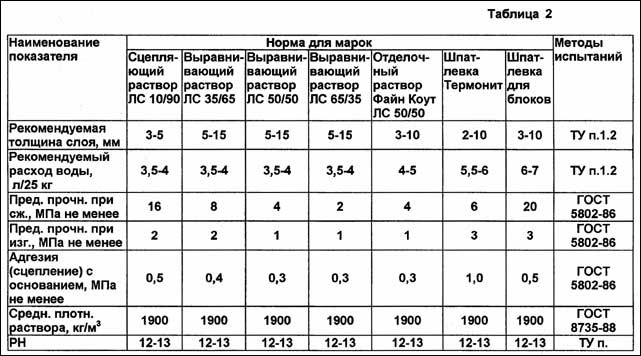

Table of characteristics of putty solutions.The process of preparing the walls involves applying a starting putty, since the surface, which is covered with cement-sand plaster or plasterboard, is unsuitable for further painting. This is due to the fact that the named compositions after application and drying acquire excessive porosity, and also perfectly absorb moisture. As a result, in the process of painting such a surface, it is not possible to achieve that the material lies evenly on the surface. As a result, there will be a significant change in the color that was chosen, in addition, all small roughness will remain visible. To prepare the walls at this stage, it is necessary to select a starting putty. Among its ingredients, it has fine-grained sand, which allows you to apply the composition in a very impressive layer, the thickness of which is 4 mm, while you can be sure that the layer will not be covered with cracks. The preparation technology at this stage involves the use of a spatula with a wide working surface (60-80 cm). While a small spatula (20-25 cm) should be used when distributing the mixture, it will also allow you to get rid of minor irregularities. The putty composition should be diluted immediately before the start of the work, but not earlier, since the period after which the composition gradually begins to harden and gain strength is limited to 45 minutes. The same rule should be followed when using ready-to-use mixtures, which must be opened before starting work.

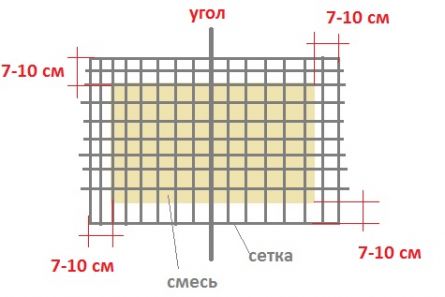

Table of characteristics of putty solutions.The process of preparing the walls involves applying a starting putty, since the surface, which is covered with cement-sand plaster or plasterboard, is unsuitable for further painting. This is due to the fact that the named compositions after application and drying acquire excessive porosity, and also perfectly absorb moisture. As a result, in the process of painting such a surface, it is not possible to achieve that the material lies evenly on the surface. As a result, there will be a significant change in the color that was chosen, in addition, all small roughness will remain visible. To prepare the walls at this stage, it is necessary to select a starting putty. Among its ingredients, it has fine-grained sand, which allows you to apply the composition in a very impressive layer, the thickness of which is 4 mm, while you can be sure that the layer will not be covered with cracks. The preparation technology at this stage involves the use of a spatula with a wide working surface (60-80 cm). While a small spatula (20-25 cm) should be used when distributing the mixture, it will also allow you to get rid of minor irregularities. The putty composition should be diluted immediately before the start of the work, but not earlier, since the period after which the composition gradually begins to harden and gain strength is limited to 45 minutes. The same rule should be followed when using ready-to-use mixtures, which must be opened before starting work. Reinforcing mesh arrangement diagram.Walls to be painted should preferably be supplemented with a reinforcing layer. To do this, prepare a nylon mesh with 2 mm cells. Apply a layer of putty up to 2 mm thick to the surface. The application should be done in the form of a strip, the width of which is equivalent to the dimensions of the mesh used. Then the reinforcing layer should be applied to the wall and pressed into the solution with a spatula. A second layer of putty should be applied over the reinforcing mesh. When preparing walls for painting, some novice craftsmen try to achieve ideal smoothness by smoothing out the protruding stripes that are obtained after running the tool along the wall surface. Experts advise against doing this, you just need to ensure that there are no depressions or areas without the mixture. After the tool has been run over the surface for the first time, it needs to be run two more times, thereby leveling the transitions between the stripes, while the remaining bumps should not be touched, they can be gotten rid of before applying the finishing putty. To avoid transition effects, do not apply the mixture in too small portions, which will be placed in the central part of a large spatula. This will not allow you to get a good result in the end. The applied layer of putty should be left for a period limited to 8 hours. Only after this is it permissible to begin processing the walls by grinding, for which you should use a coarse abrasive mesh, the grain size of which is 120. This process will rid the surface of all sorts of irregularities and protruding errors. But after this, the wall will not yet be ready for finishing painting. Return to contents</a>

Reinforcing mesh arrangement diagram.Walls to be painted should preferably be supplemented with a reinforcing layer. To do this, prepare a nylon mesh with 2 mm cells. Apply a layer of putty up to 2 mm thick to the surface. The application should be done in the form of a strip, the width of which is equivalent to the dimensions of the mesh used. Then the reinforcing layer should be applied to the wall and pressed into the solution with a spatula. A second layer of putty should be applied over the reinforcing mesh. When preparing walls for painting, some novice craftsmen try to achieve ideal smoothness by smoothing out the protruding stripes that are obtained after running the tool along the wall surface. Experts advise against doing this, you just need to ensure that there are no depressions or areas without the mixture. After the tool has been run over the surface for the first time, it needs to be run two more times, thereby leveling the transitions between the stripes, while the remaining bumps should not be touched, they can be gotten rid of before applying the finishing putty. To avoid transition effects, do not apply the mixture in too small portions, which will be placed in the central part of a large spatula. This will not allow you to get a good result in the end. The applied layer of putty should be left for a period limited to 8 hours. Only after this is it permissible to begin processing the walls by grinding, for which you should use a coarse abrasive mesh, the grain size of which is 120. This process will rid the surface of all sorts of irregularities and protruding errors. But after this, the wall will not yet be ready for finishing painting. Return to contents</a>

Finishing puttying

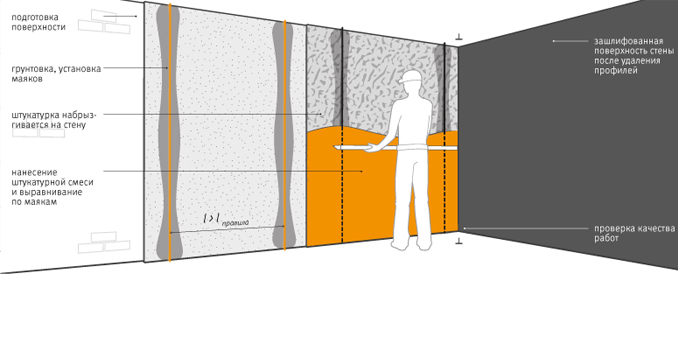

Scheme of filling a concrete wall using beacons.The next step involves eliminating the grain effect, which can be achieved by applying finishing putty. This composition does not contain sand or large-fraction inclusions among the ingredients, which allows you to get a smooth base as a result. The paint will not be able to penetrate deeply into the finishing putty layer. This composition is applied using the same technology that was used when working with the starting mixture, but the layer being arranged should not be thicker than 1.5-2 mm, otherwise it will be covered with cracks. This layer will guarantee an ideal surface, devoid of defects and bumps. Despite this, after finishing puttying, the surface must be sanded. For this, it is recommended to use an abrasive mesh that has a smaller grain size, marked 60-80. The main condition in this case is that it is impossible to allow the entire layer to be scraped off. If necessary, several layers can be applied, which is true if the previous ones did not allow you to get a normal result. You can check the correctness and quality of the work performed by using a lamp or a spotlight. The light from the source should fall at an oblique angle to the surface, only under such conditions will it be possible to see all minor errors. They must be removed by grinding, otherwise after painting they will become visible and significantly spoil the appearance of the surface.

Scheme of filling a concrete wall using beacons.The next step involves eliminating the grain effect, which can be achieved by applying finishing putty. This composition does not contain sand or large-fraction inclusions among the ingredients, which allows you to get a smooth base as a result. The paint will not be able to penetrate deeply into the finishing putty layer. This composition is applied using the same technology that was used when working with the starting mixture, but the layer being arranged should not be thicker than 1.5-2 mm, otherwise it will be covered with cracks. This layer will guarantee an ideal surface, devoid of defects and bumps. Despite this, after finishing puttying, the surface must be sanded. For this, it is recommended to use an abrasive mesh that has a smaller grain size, marked 60-80. The main condition in this case is that it is impossible to allow the entire layer to be scraped off. If necessary, several layers can be applied, which is true if the previous ones did not allow you to get a normal result. You can check the correctness and quality of the work performed by using a lamp or a spotlight. The light from the source should fall at an oblique angle to the surface, only under such conditions will it be possible to see all minor errors. They must be removed by grinding, otherwise after painting they will become visible and significantly spoil the appearance of the surface. Tools needed for wall puttying. To prepare the base, you will need to stock up on some materials and tools:

Tools needed for wall puttying. To prepare the base, you will need to stock up on some materials and tools:

- primer;

- plaster;

- putty;

- wide spatula;

- a serpent;

- abrasive mesh;

- finishing putty.

Return to Contents</a>

Priming on the wall

The final stage isthe priming process. Before this, the wall should be cleaned of dust and any remaining suspended matter that may stick after sanding. It is permissible to use a vacuum cleaner or dry rags, but you should avoid using damp cloths. If you are working with wooden walls, they only need to be sanded, and you can get rid of particularly noticeable depressions or unevenness using special grouting compounds. Then the wooden base should be treated with a protective compound and, if necessary, covered with stain. At the next stage, the wooden wall can be painted or varnished. If there are textured surfaces such as wallpaper intended for painting or decorative plaster, it is necessary to carry out the priming process. So, in the case of wallpaper, an adhesive composition should be used as a primer, while for plaster, a special primer should be used that has the property of deep penetration. Return to the table of contents</a>

Features of preparation gypsum cardboard wall for painting

Drywall must be treated firstprimer, and then putty. The primer is necessary to improve the adhesive properties of the materials being bonded. For work on gypsum boards, it is preferable to use a priming composition that does not contain a solvent. Before priming, the surface must be cleaned of dust, and then the composition must be distributed evenly over the entire area. In those places that are difficult to reach with a roller, you need to use a brush. Scheme of plasterboard joint filling.In addition to the fact that before puttying it is necessary to reinforce the seams, as described above, it is also necessary to seal the traces of the fasteners installed during installation. In order to get rid of all the defects, it is necessary to apply the finishing putty, the layer of which should be equal to 1 mm. But if you use special putties, then they should be applied in a layer of 0.2 mm, such compositions include superfinishing mixture. If it is necessary to apply the composition in several layers, you should wait until the previous one is completely dry. Otherwise, minor cracks will appear on the surface, which will be visible after painting. Next comes the turn of the grinding process, for which you should prepare:

Scheme of plasterboard joint filling.In addition to the fact that before puttying it is necessary to reinforce the seams, as described above, it is also necessary to seal the traces of the fasteners installed during installation. In order to get rid of all the defects, it is necessary to apply the finishing putty, the layer of which should be equal to 1 mm. But if you use special putties, then they should be applied in a layer of 0.2 mm, such compositions include superfinishing mixture. If it is necessary to apply the composition in several layers, you should wait until the previous one is completely dry. Otherwise, minor cracks will appear on the surface, which will be visible after painting. Next comes the turn of the grinding process, for which you should prepare:

- glasses;

- halogen lamp;

- respirator;

- brush;

- a grinding bar;

- stepladder;

- sandpaper with a grain size of 80-180.

The sandpaper you should choose is the one thatis designed for rough and final grinding. The grinding movements should be circular, this will allow you to get a uniform and high-quality result. It is preferable to carry out such work in the evening, when it is possible to use one side light source in the form of a halogen lamp. After grinding, the surface must be primed again. After preparing the plasterboard walls, water-based paint will lie well on their surface. The quality of painting will be excellent, and the cost will be acceptable. However, it is still important to carry out thorough preparation, because only in this case the paint will look good, and no errors will be visible on the wall after drying.