Today, warm film flooris perhaps the most popular type of room insulation. Warm floors help to create a very pleasant and comfortable temperature in the room, most suitable for a person. Moreover, in this case, infrared rays come directly from the floor surface, which makes it indispensable for heating children's rooms and bedrooms. In addition, using a warm floor as the only heating system allows you to get rid of bulky radiators and harmful oil heaters forever. It is important to note that the installation of such an insulation system is not particularly difficult. Therefore, many people prefer to lay a warm film floor with their own hands, without resorting to the help of specialists. Scheme of the device of a warm film floor.To install a warm film floor with your own hands, you need to know several basic rules for doing this work. As mentioned above, a warm floor is the most convenient, safe and healthy way to heat a room. Its main advantages include the following qualities:

Scheme of the device of a warm film floor.To install a warm film floor with your own hands, you need to know several basic rules for doing this work. As mentioned above, a warm floor is the most convenient, safe and healthy way to heat a room. Its main advantages include the following qualities:

Advantages of a film warm floor

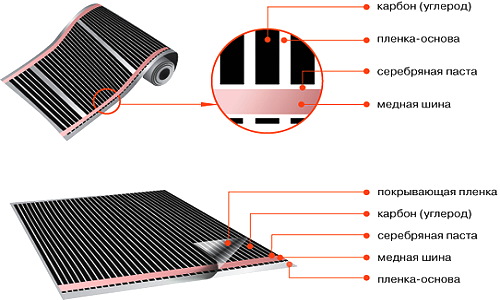

Thermal film composition.

Thermal film composition.

Return to Contents</a>

Materials and Tools

To install a heated floor yourself, you will need the following materials and tools: Advantages of film heated floors: comparison diagram with central heating.

Advantages of film heated floors: comparison diagram with central heating.

- screwdriver;

- sharp knife;

- pliers;

- side cutters;

- insulation tape;

- distribution box;

- thermoregulator;

- electric wires;

- the required amount of heating element;

- the required footage of the thermal insulating substrate.

Return to Contents</a>

Surface preparation for a film floor

Before laying the film, it is very important to properly prepare the floor surface, for which you need to perform the following simple steps: Installation diagram of a warm film floor.

Installation diagram of a warm film floor.

Now that the base is completely ready, you canstart installing a heated floor with your own hands. If, according to your plans, this heating system will be the only source of heat in this room, then the film covering should cover at least 70% of the total area of the room. If there are other sources of heat in the room, then 40-50% will be enough. It is important to remember that the film should not be laid not close to the wall. There should be at least 10 cm between the edge of the film and the wall surface. Return to the table of contents</a>

Laying a warm floor

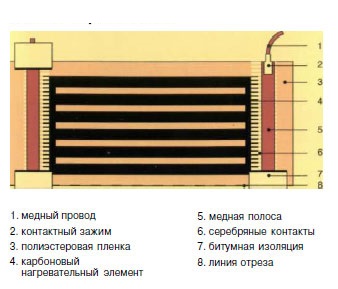

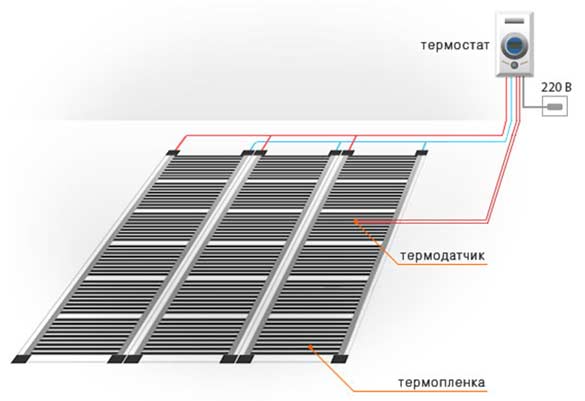

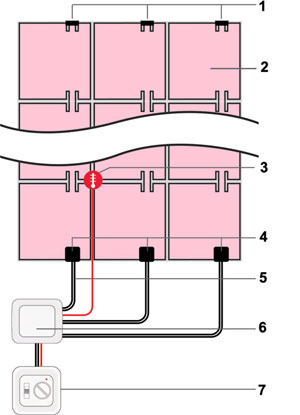

Before you start working with a warm film floor, read the instructions carefully, as different heating systems sometimes require different connection methods. Heating system installation diagram: 1 – end seals, 2 – film strips, 3 – temperature sensor, 4 – protective box, 5 – installation wires, 6 – service box, 7 – thermostat.

Heating system installation diagram: 1 – end seals, 2 – film strips, 3 – temperature sensor, 4 – protective box, 5 – installation wires, 6 – service box, 7 – thermostat.

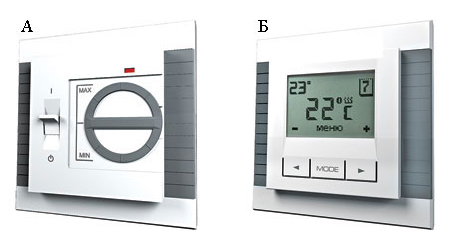

Now that the film covering is completely laid and connected, all you need to do is connect the heating control system. Thermostats, general appearance:A – universal, B – programmable. The temperature sensor should be installed in a place where it would be completely safe, but at the same time located in close proximity to the heating system. It is best to place it in the area of the room where some large piece of furniture will be located in the future, for example, a table, wardrobe or bedside table. To make the sensor less noticeable, you should cut a shallow niche in the substrate and place it there. Distribution boxes and thermostats are usually installed at a height of at least 15 cm from the floor level. It is important to remember that the film coating is very susceptible to various mechanical damages, so it is necessary to lay a layer of protective material on top of it. There are several types of materials that are used to protect the warm film floor. For example, if you decide to put a hard floor covering in your room, such as laminate, then in this case it will be quite enough to cover the film heater with ordinary polyethylene film. If you have chosen softer materials as the final floor covering, such as linoleum or carpet, then you will need to provide the heating system with more reliable protection. In this situation, you can do the following: cover the warm floor with polyethylene film, and then lay sheets of plywood or wood-fiber boards on top of it. When laying, it is important to carefully monitor so as not to accidentally damage the warm film floor, since in this case the operation of the heating system will be disrupted. A much more complex process is laying tiles or ceramic tiles on a warm film floor. In this case, as in the two previous ones, the work to protect the warm film covering begins with laying the polyethylene film. Then, on top of it, it is necessary to lay a reinforcing paint mesh made of a material that does not conduct electricity. After that, you should carefully fix this mesh on the floor surface, trying not to damage the heating elements located in the film, as well as the copper buses and the wiring connected to them. After this, you can start laying tiles, which is best done using special tile adhesive. If you have not made any mistakes and have done everything correctly, then in this case, the warm floor installed by your own hands will please you and all your loved ones for many years.

Thermostats, general appearance:A – universal, B – programmable. The temperature sensor should be installed in a place where it would be completely safe, but at the same time located in close proximity to the heating system. It is best to place it in the area of the room where some large piece of furniture will be located in the future, for example, a table, wardrobe or bedside table. To make the sensor less noticeable, you should cut a shallow niche in the substrate and place it there. Distribution boxes and thermostats are usually installed at a height of at least 15 cm from the floor level. It is important to remember that the film coating is very susceptible to various mechanical damages, so it is necessary to lay a layer of protective material on top of it. There are several types of materials that are used to protect the warm film floor. For example, if you decide to put a hard floor covering in your room, such as laminate, then in this case it will be quite enough to cover the film heater with ordinary polyethylene film. If you have chosen softer materials as the final floor covering, such as linoleum or carpet, then you will need to provide the heating system with more reliable protection. In this situation, you can do the following: cover the warm floor with polyethylene film, and then lay sheets of plywood or wood-fiber boards on top of it. When laying, it is important to carefully monitor so as not to accidentally damage the warm film floor, since in this case the operation of the heating system will be disrupted. A much more complex process is laying tiles or ceramic tiles on a warm film floor. In this case, as in the two previous ones, the work to protect the warm film covering begins with laying the polyethylene film. Then, on top of it, it is necessary to lay a reinforcing paint mesh made of a material that does not conduct electricity. After that, you should carefully fix this mesh on the floor surface, trying not to damage the heating elements located in the film, as well as the copper buses and the wiring connected to them. After this, you can start laying tiles, which is best done using special tile adhesive. If you have not made any mistakes and have done everything correctly, then in this case, the warm floor installed by your own hands will please you and all your loved ones for many years.