Утепление пола является очень важной задачей в providing warmth and comfort in the room. This issue is especially important when the apartment is located on the 1st floor, when there is a basement underneath it. Insulation of the floor covering from the basement side is also relevant in a private cottage. Options for insulating the floor above the basement.

Options for insulating the floor above the basement.

What is the purpose of warming?

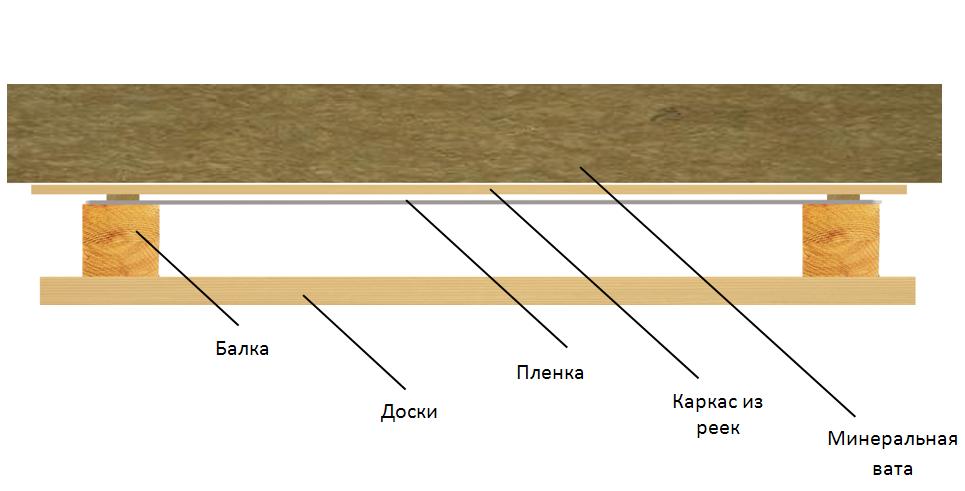

The process of heat exchange in a private house or apartmentvery often depends on the floor structure, since their surface is the place of greatest heat loss. This is especially true when the floor base is made of concrete. Concrete is a durable material with good performance properties, so it is very often used to make the floor base. Scheme of insulation of basement ceiling with mineral woolcotton wool. Despite its good characteristics, concrete is also a very cold material. If concrete flooring is used in a residential area, it will need to be insulated well enough, otherwise any heating will be ineffective. The presence of a cold surface will create uncomfortable conditions for staying in the room, which will lead to high heating costs. In addition, if there is no thermal insulation of the surface under which the basement is located, this will cause the formation of dampness and mold on the surface of the walls. To avoid this, it is necessary to arrange a high-quality insulating structure. At the same time, floor insulation is a fairly simple procedure. Any owner of the premises can do it on their own, having the necessary material and tools. Return to contents</a>

Scheme of insulation of basement ceiling with mineral woolcotton wool. Despite its good characteristics, concrete is also a very cold material. If concrete flooring is used in a residential area, it will need to be insulated well enough, otherwise any heating will be ineffective. The presence of a cold surface will create uncomfortable conditions for staying in the room, which will lead to high heating costs. In addition, if there is no thermal insulation of the surface under which the basement is located, this will cause the formation of dampness and mold on the surface of the walls. To avoid this, it is necessary to arrange a high-quality insulating structure. At the same time, floor insulation is a fairly simple procedure. Any owner of the premises can do it on their own, having the necessary material and tools. Return to contents</a>

Material selection

Currently, there are on the construction marketseveral types of insulation material. This material is available in bulk, liquid, roll and block form. Any of them can be used to insulate a room with a basement underneath. Various slabs and mats are used as block material. This type of insulation has a low thermal conductivity coefficient and is lightweight. Block insulation is very good for use on the basement side. They can be used together with roll material, which will improve overall thermal insulation. The block type of material is made of mineral wool, foam plastic, basalt fibers or other materials with a composite structure. Scheme of floor insulation with expanded clay. The following are considered bulk materials:

Scheme of floor insulation with expanded clay. The following are considered bulk materials:

- expanded clay;

- sawdust;

- polystyrene crumb;

- slag waste.

Their use will allow you to completely fillfree space between the floor surface and its base. Bulk materials can be used directly on open ground or in any private building with a cold basement below. Mineral wool, any composite with a cork base or any multilayer foil-based insulation can be used as a roll insulation. The thickness of such materials can be different, but is generally 8-10 cm. Various cement-based solutions containing foam plastic chips, wood shavings, expanded clay or other similar materials are used as liquid insulation. Foamed polymer floors based on penoizol are currently widely used. To lay it, you need to use specialized equipment. Which is quite difficult to do on your own. Return to contents</a>

How to perform insulation?

To perform the required work correctly,the first thing you need to do is dismantle the old coating. This should be done carefully so that you can reuse it later. To insulate a floor with a basement underneath, you must take into account the load that will occur on all layers of the structure. To minimize them, all the material must be laid in a certain sequence. To perform all installation work, you will need the following tool: Tools for floor insulation.

Tools for floor insulation.

- Screwdriver;

- Screwdriver Set;

- a hammer;

- knife;

- building level.

The first step is to dismantle it.old coating. After the old coating is removed, it is necessary to inspect the logs. Damaged logs will need to be replaced. After that, they must be treated with an antifungal antiseptic, which will help to avoid mold on their surface in the future. Once the antiseptic dries, you can lay the waterproofing. After that, the necessary insulation is laid. If the height of the logs is quite high, you can lay 2 layers of material. Here you can combine insulation on different layers (bulk and roll). Then you need to put a vapor barrier film, and on it a plywood board. On top of the plywood, you can lay a thin roll material (backing), the thickness of which is 1-4 mm. And only then the finished surface is finally laid out. At the stage of building a house, it is better to do preliminary insulation. It is carried out in the same order. This will avoid further problems during operation. Return to the table of contents</a>

Carrying out works in the basement with your own hands

Scheme of floor insulation in the room above the basement.If possible, insulation work can be done from the basement side. It is done on the basement ceiling. Foam plastic is best suited for this, since it is not afraid of high humidity. Foam plastic is glued to the ceiling surface with special glue. After the glue dries, the gaps between the slabs must be filled with polyurethane foam. When the foam hardens, its excess must be removed with a knife. You can also use other similar materials. But foam plastic is one of the most inexpensive. Moreover, if damaged, it can be easily replaced. In order for the insulation to perform its functions well after the work, the seams between the layers of vapor barrier and waterproofing film must be sealed with tape. This will ensure their tightness. To prevent condensation from forming on the insulation in the future, the ventilation openings must not be closed. The presence of ventilation will also help keep the flooring in good condition. In the case where the apartment is on the 1st floor and there is a basement underneath it, you should not put off the installation of insulation for a long time. If you delay, the room will be cold and damp. And in the future, this will lead to the formation of fungi and mold not only on the floor surface, but also on the walls.

Scheme of floor insulation in the room above the basement.If possible, insulation work can be done from the basement side. It is done on the basement ceiling. Foam plastic is best suited for this, since it is not afraid of high humidity. Foam plastic is glued to the ceiling surface with special glue. After the glue dries, the gaps between the slabs must be filled with polyurethane foam. When the foam hardens, its excess must be removed with a knife. You can also use other similar materials. But foam plastic is one of the most inexpensive. Moreover, if damaged, it can be easily replaced. In order for the insulation to perform its functions well after the work, the seams between the layers of vapor barrier and waterproofing film must be sealed with tape. This will ensure their tightness. To prevent condensation from forming on the insulation in the future, the ventilation openings must not be closed. The presence of ventilation will also help keep the flooring in good condition. In the case where the apartment is on the 1st floor and there is a basement underneath it, you should not put off the installation of insulation for a long time. If you delay, the room will be cold and damp. And in the future, this will lead to the formation of fungi and mold not only on the floor surface, but also on the walls.