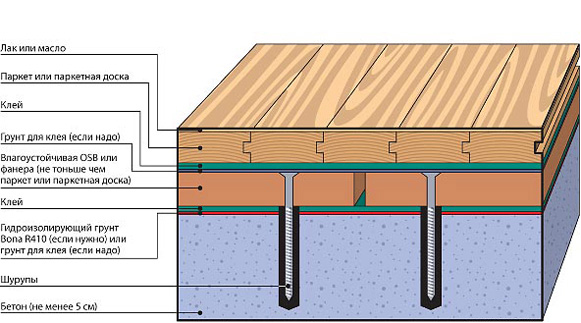

If you choose flooringlaminate, you need to know that the technology of its installation requires preliminary leveling of the floor. If the surface has any defects, after some time the coating will start to creak, the locks will loosen, and the panels themselves may crack. Therefore, the process must be approached with full responsibility. Scheme of floor leveling with moisture-resistant plywood.

Scheme of floor leveling with moisture-resistant plywood.

What happens if you do not level the floor?

Before considering existing methodsfloor leveling, you need to know what will happen if the floor is not leveled. From a human height, the floor may look perfectly level. Minor differences are not noticeable and are practically not felt. But for laminate, such differences can be fatal. On any kind of unevenness, the coating will feel very bad. If the floor is not pre-leveled, after some time, unevenness will begin to appear at the joints between the panels, the boards themselves will “slap”, and the ends will stick out. As a result, the locks will break, and the beautiful coating will turn into a set of poorly fastened panels. That is why the process of floor leveling must be approached with the utmost responsibility. There are different methods of leveling. First of all, you need to consider what the floor is made of. The procedure for leveling the floor under the laminate will differ depending on whether you need to level a concrete surface or a wooden base. Return to contents</a>

Step-by-step instruction for leveling concrete screed

Tools for floor leveling.This method is suitable in a situation where it is required to have a poorly made base or an ordinary slab. Preparing the floor for laminate flooring begins with dismantling the old covering and cleaning it from all kinds of debris. All the methods discussed below will require a certain set of tools. It may vary slightly depending on which method is used, but these devices are usually mandatory:

Tools for floor leveling.This method is suitable in a situation where it is required to have a poorly made base or an ordinary slab. Preparing the floor for laminate flooring begins with dismantling the old covering and cleaning it from all kinds of debris. All the methods discussed below will require a certain set of tools. It may vary slightly depending on which method is used, but these devices are usually mandatory:

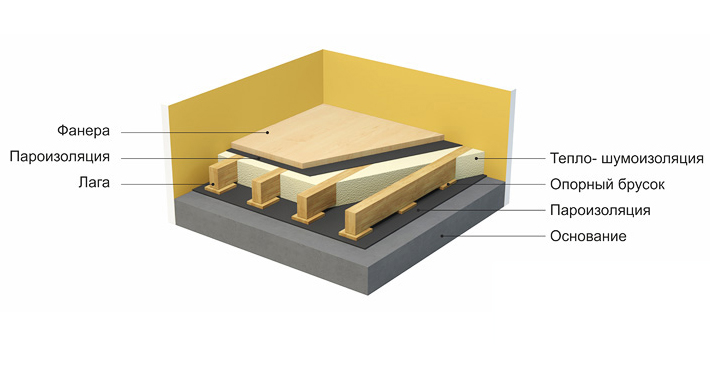

This is the method of leveling the floor for laminate flooring.involves a sequence of actions. First of all, you will need to take a building level and find the highest point of the floor. Next, a line of walls is marked along the perimeter, up to which the concrete solution will be poured. A cord is pulled and beacons are installed. They must be fixed to the surface using mounds of concrete solution prepared from one part cement, three parts sand, about five parts crushed stone and enough water so that the solution is similar in consistency to thick sour cream. Check the horizontality of the beacons using a level. Scheme of floor leveling with concrete screed.Replace the screed solution. It is more convenient if you have a drill with a special mixer attachment at hand. Pour the solution to the previously marked level, using the beacons as a guide. Carefully level the poured screed. Take a rule, press it against the beacons installed nearby and pull it towards you. Excess solution will collect at the end of the surface or spread over the voids. The poured concrete must be rolled over the entire surface with a needle roller to remove bubbles. For 2 days, the poured concrete will need to be regularly moistened with water. After 2 days, remove the beacons. Fill the resulting voids with solution and rub. After this, the floor will need to be covered with polyethylene film and left to dry for 14 days. After the screed has completely dried, you can lay the laminate. Return to the table of contents</a>

Scheme of floor leveling with concrete screed.Replace the screed solution. It is more convenient if you have a drill with a special mixer attachment at hand. Pour the solution to the previously marked level, using the beacons as a guide. Carefully level the poured screed. Take a rule, press it against the beacons installed nearby and pull it towards you. Excess solution will collect at the end of the surface or spread over the voids. The poured concrete must be rolled over the entire surface with a needle roller to remove bubbles. For 2 days, the poured concrete will need to be regularly moistened with water. After 2 days, remove the beacons. Fill the resulting voids with solution and rub. After this, the floor will need to be covered with polyethylene film and left to dry for 14 days. After the screed has completely dried, you can lay the laminate. Return to the table of contents</a>

Guidelines for the use of a self-leveling compound

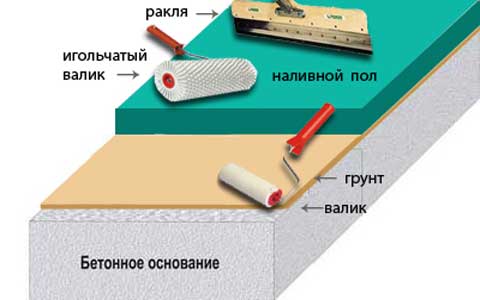

This method can be usedin situations where the surface does not have too many defects. Self-leveling mixture allows you to effectively eliminate differences and unevenness that do not exceed 0.5 cm. The use of such mixtures does not require preliminary installation of beacons. The work is carried out in the following order:

Scheme of the self-leveling floor.It is important to fill in several stages, because the ready mixture can only be used for 15 minutes after preparation. After filling the entire space, the mixture must be allowed to dry. This requires three days. There should not be even the slightest draft in the room. After the mixture has dried, you can begin installing the laminate. Return to contents</a>

Scheme of the self-leveling floor.It is important to fill in several stages, because the ready mixture can only be used for 15 minutes after preparation. After filling the entire space, the mixture must be allowed to dry. This requires three days. There should not be even the slightest draft in the room. After the mixture has dried, you can begin installing the laminate. Return to contents</a>

Alignment with sheets of plywood and chipboard

This method can only be used if the ceilingsin the room have such a height that allows to reduce the space by approximately 10 cm, since this technology involves laying sheets on pre-installed joists. The work is carried out in the following sequence:

The main advantage of this method isthat the covering can be laid immediately after the plywood base is installed. However, this method is only suitable for rooms with fairly high ceilings. Return to contents</a>

The procedure for leveling the wooden floor

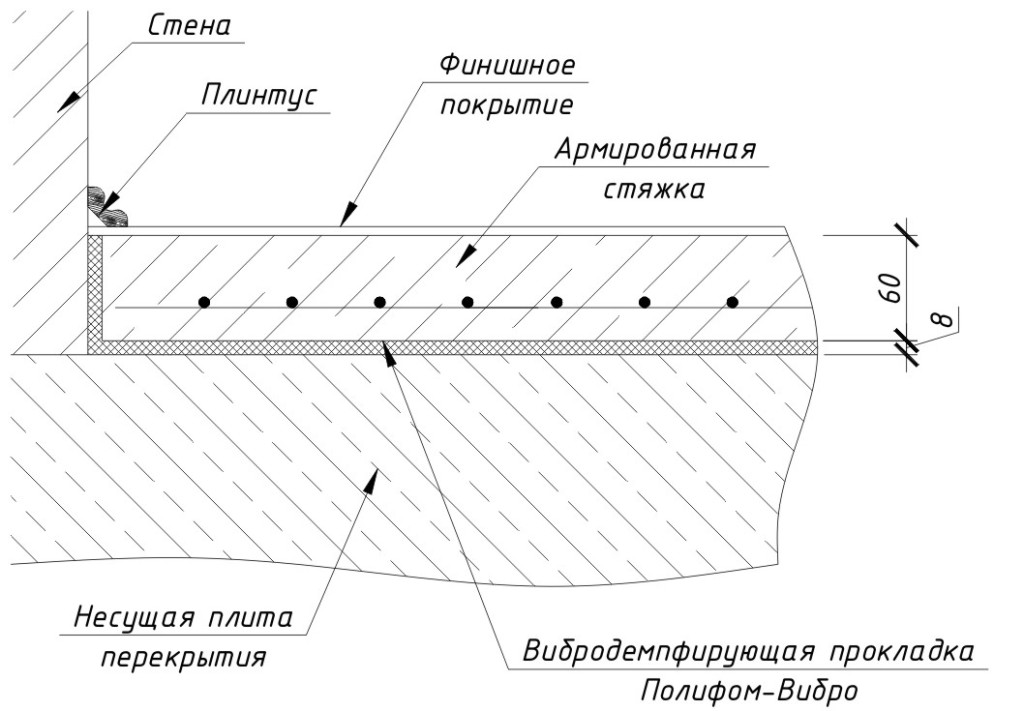

Scheme of leveling a wooden floor on joists.If the floor is made of wood and there are large differences in level, you will need to disassemble and level the joists. Some boards or joists will need to be replaced. If the surface is relatively flat, it will be enough to use one of the following methods. One of the most common ways to level a wooden floor is the scraping method. It can be used to create the most even surface possible. It is done manually, which is very difficult and time-consuming, or with a special machine. First, you need to sink the screws and nails on the surface. To do this, use a punch or other convenient means. The scraping machine removes the top layer of wood, resulting in a flat rough surface. After this, all that remains is to thoroughly remove all the dust, and you can start laying the laminate. The floor can be leveled using chipboard or plywood. Everything is done almost the same way as with a concrete floor. Joists are laid on top of the old wooden base. Use screws to secure them. Place waterproofing, soundproofing and heat-insulating material between the joists. The floor can be leveled using PVA glue and sawdust. This is the cheapest method. It is only suitable for leveling surfaces without significant dips and other defects. The big advantage of this type of puttying is that the floor level does not rise significantly when using it. The work is performed in the following sequence:

Scheme of leveling a wooden floor on joists.If the floor is made of wood and there are large differences in level, you will need to disassemble and level the joists. Some boards or joists will need to be replaced. If the surface is relatively flat, it will be enough to use one of the following methods. One of the most common ways to level a wooden floor is the scraping method. It can be used to create the most even surface possible. It is done manually, which is very difficult and time-consuming, or with a special machine. First, you need to sink the screws and nails on the surface. To do this, use a punch or other convenient means. The scraping machine removes the top layer of wood, resulting in a flat rough surface. After this, all that remains is to thoroughly remove all the dust, and you can start laying the laminate. The floor can be leveled using chipboard or plywood. Everything is done almost the same way as with a concrete floor. Joists are laid on top of the old wooden base. Use screws to secure them. Place waterproofing, soundproofing and heat-insulating material between the joists. The floor can be leveled using PVA glue and sawdust. This is the cheapest method. It is only suitable for leveling surfaces without significant dips and other defects. The big advantage of this type of puttying is that the floor level does not rise significantly when using it. The work is performed in the following sequence:

Be sure to take into account the fact that thisthe mixture will shrink significantly. Because of this, the putty will have to be applied in 2-3 stages. After the glue has completely hardened, it is necessary to lay a layer of plywood 0.5 cm thick. The sheets are fixed with countersunk screws. Thus, the choice of a specific method depends on the material of manufacture and the condition of the floor. Having studied the features of each method, you can choose the most suitable for your case. Good luck!