Laminate is a great material forfinishing of floors in residential, commercial and public spaces. It is characterized by high performance properties and a long service life. However, in order for this to be the case, it is necessary to know a number of important nuances and perform in strict accordance with the instructions. One of the most important is the preparatory stage. Before starting the main work, you need to properly prepare the floor and figure out where to start laying the flooring. Where you need to start depends primarily on the characteristics of the room and the chosen installation method. However, first you need to prepare the working tools. Laminate has high performance properties and a long service life.

Laminate has high performance properties and a long service life.

Preparation of tools for laminate mounting

To properly install laminate flooring,First of all, you need to collect the necessary set of tools. The tools are quite simple and accessible. Even a person without much experience will be able to understand the features of their use and then lay the laminate. So, before you start laying the flooring, prepare the following: Tools for laying laminate flooring.

Tools for laying laminate flooring.

Prepare all these tools.Next, before you start laying, you will need to make a calculation that will allow you to determine the required number of panels. Laminate of different classes is available for sale. The class is determined by the strength of the panels and related characteristics. In an apartment or house, it is best to use class 32 panels. They are highly durable and have excellent performance properties. Suitable for laying in the bedroom, kitchen, living room, hallway and other rooms. Return to contents</a>

Instructions for calculating the required amount of laminate

Laminate flooring must be laid carefullyget ready. Before starting the calculation, decide which installation method will be used. In the case of installation using the traditional rectangular method, the calculation is performed in the following sequence: Calculation of the required amount of laminate.

Calculation of the required amount of laminate.

Perfect for small spacesdiagonal. It allows you to visually enlarge the room and looks more original, but requires more material. The calculation is performed in the following sequence:

Once you have calculated the required amount of laminate, you can proceed to surface preparation. Return to Contents</a>

Recommendations for the preliminary preparation of the base for the laying of panels

Preparing the floor for laying laminate.Before figuring out where to start laying laminate panels, you will need to perform a number of preparatory activities. Unlike most other floor coverings, laminate is very demanding of the quality of the base. It must be flat and smooth. You can only do this after the concrete has completely dried. On average, this takes 25 days from the moment of pouring. The concrete must be covered with polyethylene film. The joints are sealed with tape. You can start laying the laminate on a wooden base only after you have made sure that there are no fungi or various pests. When laying on a wooden base, it is most convenient to level it with chipboard or plywood sheets. This method eliminates the need to use a vapor barrier layer. Laminate can be laid on linoleum and tiles. If the surface does not have significant irregularities, it is permissible to lay the laminate without first dismantling the old coating. It is enough to just lay the underlay, and you can start assembling the panels. If the surface has many significant differences, it should be primed first, and then filled with a self-leveling mixture. It dries much faster than concrete screed. Fill according to the manufacturer's instructions. Return to contents</a>

Preparing the floor for laying laminate.Before figuring out where to start laying laminate panels, you will need to perform a number of preparatory activities. Unlike most other floor coverings, laminate is very demanding of the quality of the base. It must be flat and smooth. You can only do this after the concrete has completely dried. On average, this takes 25 days from the moment of pouring. The concrete must be covered with polyethylene film. The joints are sealed with tape. You can start laying the laminate on a wooden base only after you have made sure that there are no fungi or various pests. When laying on a wooden base, it is most convenient to level it with chipboard or plywood sheets. This method eliminates the need to use a vapor barrier layer. Laminate can be laid on linoleum and tiles. If the surface does not have significant irregularities, it is permissible to lay the laminate without first dismantling the old coating. It is enough to just lay the underlay, and you can start assembling the panels. If the surface has many significant differences, it should be primed first, and then filled with a self-leveling mixture. It dries much faster than concrete screed. Fill according to the manufacturer's instructions. Return to contents</a>

How can the panels be arranged?

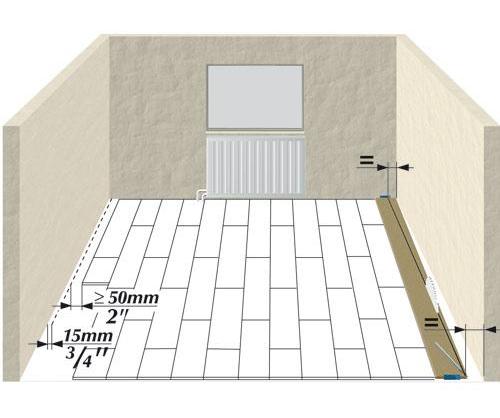

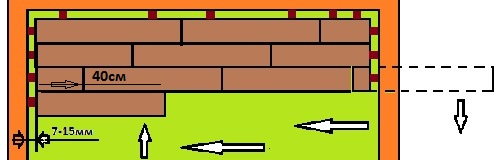

Scheme of laying laminate using the classic method.As a rule, laminate is installed parallel to the direction of light. But the specifics of a particular room and design ideas may dictate other methods of installation. Each of these solutions can significantly change the aesthetic component of the room. Therefore, first of all, it is necessary to consider in relation to the window opening. This is a classic method, according to which the panels are mounted parallel to the direction of light. The method involves the sequential installation of the cut part of the previous row at the beginning of the next row. The method allows you to minimize the amount of waste and ensure the most efficient use of materials. The checkerboard method of installation is similar to brickwork. In this case, the rows of panels are shifted by half of one panel. It is best suited for laying single-strip products.

Scheme of laying laminate using the classic method.As a rule, laminate is installed parallel to the direction of light. But the specifics of a particular room and design ideas may dictate other methods of installation. Each of these solutions can significantly change the aesthetic component of the room. Therefore, first of all, it is necessary to consider in relation to the window opening. This is a classic method, according to which the panels are mounted parallel to the direction of light. The method involves the sequential installation of the cut part of the previous row at the beginning of the next row. The method allows you to minimize the amount of waste and ensure the most efficient use of materials. The checkerboard method of installation is similar to brickwork. In this case, the rows of panels are shifted by half of one panel. It is best suited for laying single-strip products. Diagonal laminate flooring layout diagram.Using the diagonal method of laying, you can visually transform a small room. Laminate laid using this method will make the room visually more spacious and airy. It is perfect for rooms with a corner door. As for the direction of the light flow, using this method allows you to either focus on the floor finish or visually change the geometry of the room. Traditionally, the first panel of laminate is laid in the corner of the room on the window side. Return to contents</a>

Diagonal laminate flooring layout diagram.Using the diagonal method of laying, you can visually transform a small room. Laminate laid using this method will make the room visually more spacious and airy. It is perfect for rooms with a corner door. As for the direction of the light flow, using this method allows you to either focus on the floor finish or visually change the geometry of the room. Traditionally, the first panel of laminate is laid in the corner of the room on the window side. Return to contents</a>

Step-by-step instruction for laying laminate

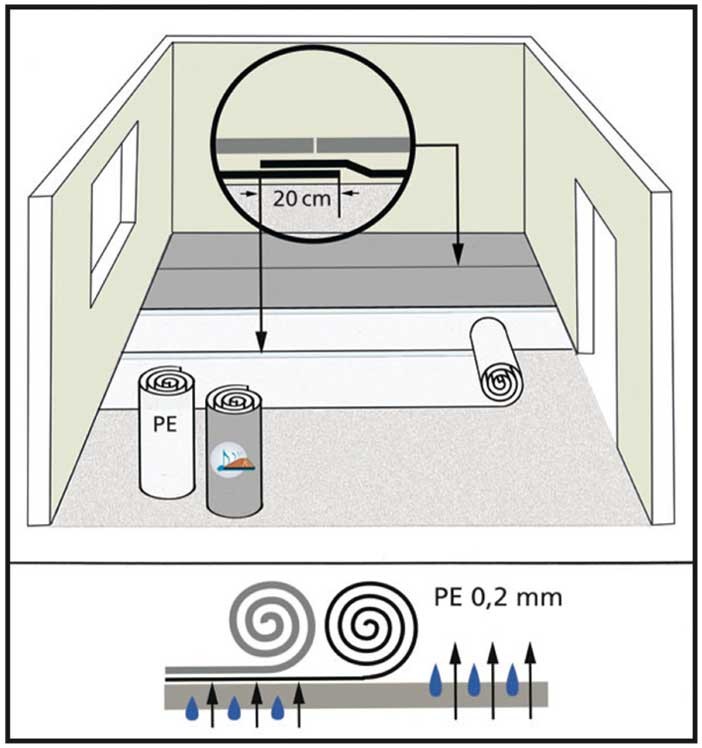

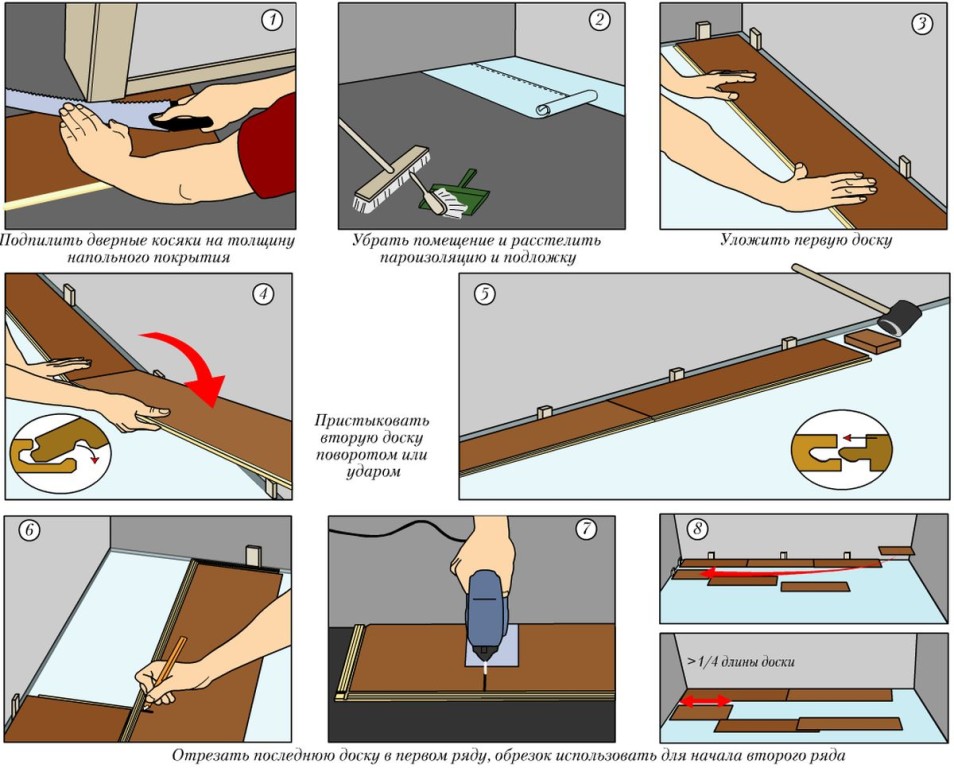

During the installation of the panel, it will inevitably be necessarycut. It is better to use a jigsaw for this. If you don’t have one, a hacksaw will do. However, when working with a hacksaw, you need to be extremely careful not to tear the inner film. A milling cutter is used to create holes for pipes. The panels themselves are mounted in a certain sequence. First, the underlay is laid. It simultaneously functions as a shock absorber, noise and vapor insulator. When laying panels on a concrete base, use a 3 mm thick underlay. For a wooden base, a 2 mm thick material will be sufficient. For residential premises, it is recommended to use a cork or polypropylene underlay. Cork material is more expensive, but it has higher soundproofing properties. The underlay must be laid end to end, without overlapping. Use tape to fasten the strips. Be sure to take into account the fact that the panels can only be laid on a flat surface. The differences in level should not exceed 2 mm per 1 m of floor. Scheme of laying the underlay for laminate.Clean the base from all debris. Vacuum it. Traditionally, laying is done from the window opening (from the corner) to the door. Spread a roll of underlay along the long wall of the room. Gradually fill the entire room with underlay, fastening adjacent strips with tape. After all the underlay is laid, proceed to laying the first row of panels. Standard sizes of laminate panels are 126x18.5 or 138x19.5 cm. The plate can be 6-12 mm thick. There are special locks along the edges of each panel, thanks to which they are fastened together. After laying the first plate, wedges must be inserted between it and the wall to ensure a gap of 1.5 cm. This gap will compensate for the linear expansion of the covering. If there is no gap, the panels will bend over time. Insert the second board into the end lock of the first and lay it. Also insert wedges between this plate and the wall. Lay the first row to the end. In most cases, the last panel has to be trimmed. To do this, turn the plate face down, place it end-on to the wall and draw a line, focusing on the penultimate panel. Use a wax pencil or marker and a square. Cut a part of the plate to size and lay it in place.

Scheme of laying the underlay for laminate.Clean the base from all debris. Vacuum it. Traditionally, laying is done from the window opening (from the corner) to the door. Spread a roll of underlay along the long wall of the room. Gradually fill the entire room with underlay, fastening adjacent strips with tape. After all the underlay is laid, proceed to laying the first row of panels. Standard sizes of laminate panels are 126x18.5 or 138x19.5 cm. The plate can be 6-12 mm thick. There are special locks along the edges of each panel, thanks to which they are fastened together. After laying the first plate, wedges must be inserted between it and the wall to ensure a gap of 1.5 cm. This gap will compensate for the linear expansion of the covering. If there is no gap, the panels will bend over time. Insert the second board into the end lock of the first and lay it. Also insert wedges between this plate and the wall. Lay the first row to the end. In most cases, the last panel has to be trimmed. To do this, turn the plate face down, place it end-on to the wall and draw a line, focusing on the penultimate panel. Use a wax pencil or marker and a square. Cut a part of the plate to size and lay it in place. Step-by-step installation of laminate flooring: steps 1-8.Start laying the next row with the remaining piece of the last panel of the starting row. This will ensure the most rational use of material. If you do not want to save money, you can start laying the second row with a whole plate. The second row is laid in the same way as the first, only without using wedges. After completing its laying, insert the wedges of the panels into the wedges of the plates of the first row. To do this, you need to lift the 2nd row by about 30 ° and insert the panels into the lock. When lowering, you will hear a click, indicating that the plates are fastened. Install the next rows in the same way as the first two. Do not forget about the wedges, which must be installed along the perimeter of the room between the laminate panels and the walls. It is important to know about the features of laying panels in a doorway. It differs from conventional installation in that a smaller gap must be made between the plate and the door. Later, it will be covered by the door frame. Near the walls, the gap will be hidden by baseboards. It is important to know about some rules for joining panels to tiles. First of all, the joint is made using specially designed metal thresholds. In order to join laminate panels with tiles, it is necessary to first make holes in the cement-sand screed.

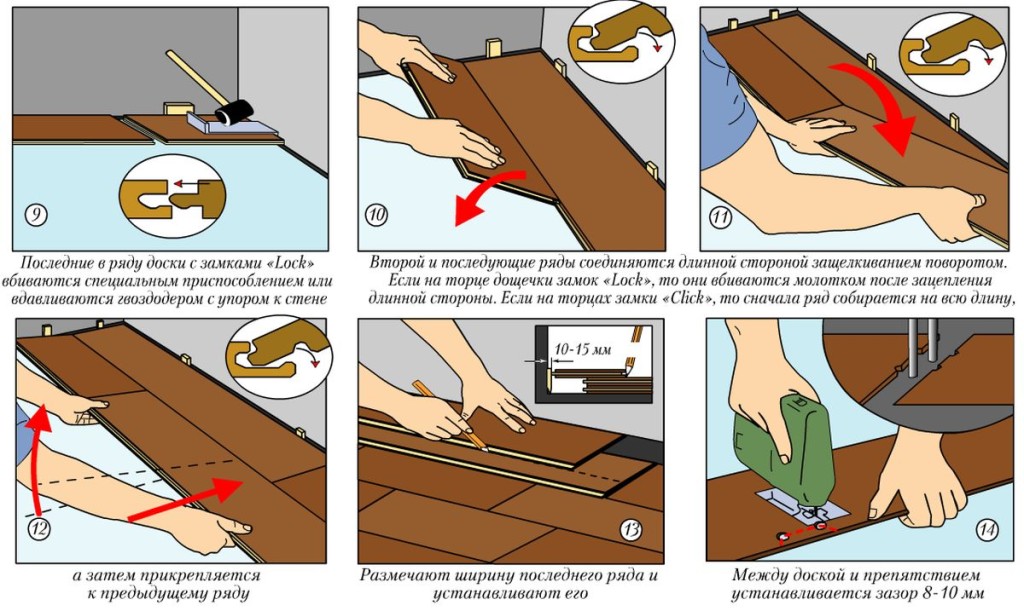

Step-by-step installation of laminate flooring: steps 1-8.Start laying the next row with the remaining piece of the last panel of the starting row. This will ensure the most rational use of material. If you do not want to save money, you can start laying the second row with a whole plate. The second row is laid in the same way as the first, only without using wedges. After completing its laying, insert the wedges of the panels into the wedges of the plates of the first row. To do this, you need to lift the 2nd row by about 30 ° and insert the panels into the lock. When lowering, you will hear a click, indicating that the plates are fastened. Install the next rows in the same way as the first two. Do not forget about the wedges, which must be installed along the perimeter of the room between the laminate panels and the walls. It is important to know about the features of laying panels in a doorway. It differs from conventional installation in that a smaller gap must be made between the plate and the door. Later, it will be covered by the door frame. Near the walls, the gap will be hidden by baseboards. It is important to know about some rules for joining panels to tiles. First of all, the joint is made using specially designed metal thresholds. In order to join laminate panels with tiles, it is necessary to first make holes in the cement-sand screed. Step-by-step installation of laminate flooring: steps 9-14.They are made with a step of 10 cm. Plastic dowels are driven into these holes. This technique allows for installation with minimal time costs. Next, you will need to insert the heads of the nails into the groove of the threshold. The nails are distributed along the threshold in accordance with the previously driven dowels. The threshold must be pressed to the floor and tapped with a hammer, using a wooden extension. The installed threshold will press the laminate board to the floor surface. The threshold has a rounded surface that will prevent a person from tripping when entering the room. Such thresholds are widely available in any store specializing in the sale of building materials. After all the laminate panels are laid, it remains to mount the baseboard. For this, you will need several tools, namely:

Step-by-step installation of laminate flooring: steps 9-14.They are made with a step of 10 cm. Plastic dowels are driven into these holes. This technique allows for installation with minimal time costs. Next, you will need to insert the heads of the nails into the groove of the threshold. The nails are distributed along the threshold in accordance with the previously driven dowels. The threshold must be pressed to the floor and tapped with a hammer, using a wooden extension. The installed threshold will press the laminate board to the floor surface. The threshold has a rounded surface that will prevent a person from tripping when entering the room. Such thresholds are widely available in any store specializing in the sale of building materials. After all the laminate panels are laid, it remains to mount the baseboard. For this, you will need several tools, namely:

Install the baseboard.At this point, the installation of the laminate can be considered complete. In order for the panels to serve for as long as possible, it is important to follow some recommendations for their further use. Return to contents</a>

Recommendations for the use of laminate

Laminate can be washed with special detergentsmeans or a washing vacuum cleaner. Remember that laminate cannot be used to cover floors in rooms with high humidity and frequent water spills. That is, it is prohibited to lay laminate in the toilet and bathroom - it will very quickly become unusable. If you spill water on the flooring in other rooms, clean it up immediately. During operation, various small defects may appear on the surface. You can easily eliminate them with a special grout. In addition, such grouts allow you to eliminate defects due to improper installation of panels. Grout also allows you to correct large differences and cracks at the joints of laminate panels. Such grouts consist of sealant, silicone and other substances. Such treatment allows you to increase the service life of the panels and maintain their original quality for a longer period. Laminate is not very demanding in care. For washing, you can use special laminate care products, which are widely available in any household chemicals store. A washing vacuum cleaner is great for cleaning. If there is none, use a soft damp cloth with a specially designed product for laminate. After wet cleaning, wipe the flooring thoroughly. Do not forget that water is one of the worst enemies of flooring. Thus, the installation of laminate panels traditionally begins from the corner near the window opening and is carried out in the direction of the door. The main thing is to correctly calculate the required number of panels and buy high-quality material, and the installation itself will not cause you any particular difficulties. Do everything according to the instructions provided, and the finished flooring will delight you with its quality and excellent appearance for many years. Good luck with your work!

Laminate can be washed with special detergentsmeans or a washing vacuum cleaner. Remember that laminate cannot be used to cover floors in rooms with high humidity and frequent water spills. That is, it is prohibited to lay laminate in the toilet and bathroom - it will very quickly become unusable. If you spill water on the flooring in other rooms, clean it up immediately. During operation, various small defects may appear on the surface. You can easily eliminate them with a special grout. In addition, such grouts allow you to eliminate defects due to improper installation of panels. Grout also allows you to correct large differences and cracks at the joints of laminate panels. Such grouts consist of sealant, silicone and other substances. Such treatment allows you to increase the service life of the panels and maintain their original quality for a longer period. Laminate is not very demanding in care. For washing, you can use special laminate care products, which are widely available in any household chemicals store. A washing vacuum cleaner is great for cleaning. If there is none, use a soft damp cloth with a specially designed product for laminate. After wet cleaning, wipe the flooring thoroughly. Do not forget that water is one of the worst enemies of flooring. Thus, the installation of laminate panels traditionally begins from the corner near the window opening and is carried out in the direction of the door. The main thing is to correctly calculate the required number of panels and buy high-quality material, and the installation itself will not cause you any particular difficulties. Do everything according to the instructions provided, and the finished flooring will delight you with its quality and excellent appearance for many years. Good luck with your work!