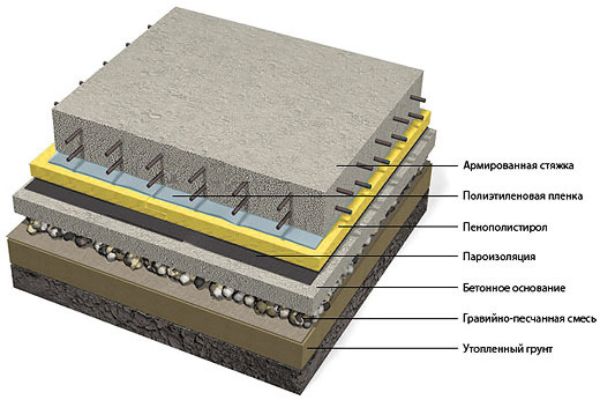

More and more developers are using it in constructionOSB boards (OSB, OSB). Despite some kinship with chipboard, this material has unique characteristics of water resistance, strength and elasticity, and it is also much lighter than its predecessor. OSB is a further development of pressed wood chipboard, but rather long wood chips (up to 14 cm) are pressed in the oriented strand board. Their thickness is less than a millimeter, but the chips in one layer are oriented in one direction, and the direction of the chips in each subsequent layer is perpendicular to the previous one, which significantly improves the properties of the material. Scheme of the device of a concrete floor on the ground.

Scheme of the device of a concrete floor on the ground.

Which plates are used for the floor?

OSB boards, the number of layers of which can bereach 3 or 4, are pressed with non-mineral resins. Often, the use of compounds containing formaldehyde in the production of OSB products makes it impossible to use the boards in interior decoration, but sheets manufactured according to the OSB-3 standard do not emit harmful substances and can be installed in rooms with high humidity. OSB boards of this type are best suited for floor installation. Experts recommend making flooring from boards produced by well-known manufacturers. As a rule, the highest quality products are manufactured in European countries, Canada and the USA, which most closely follow the environmental requirements for boards. OSB flooring can also be a finishing coating, since the external texture of the board looks quite interesting. It can be used for finishing with other materials. However, the installation of OSB itself requires a preparatory stage. How to level the floor before laying OSB boards will be discussed below. Return to contents</a>

Laying slabs on a concrete surface

Elements for fastening OSB.Quite often, in order not to lose the height of the ceilings in the room, builders lay OSB on a concrete screed. Of course, in this case, the base must be level. You can provide an ideal surface by removing the old coating and pouring a new one. Although oriented strand boards are not afraid of moisture, the base needs additional waterproofing. This will protect the space under the slab from condensation and mold. After laying on the surface of roofing felt or polyethylene cleared of old screed, beacons are installed and secured with plaster. To align them, use a level, a chalk line, a tape measure and cross threads. Now more about how to level the floor using these devices:

Elements for fastening OSB.Quite often, in order not to lose the height of the ceilings in the room, builders lay OSB on a concrete screed. Of course, in this case, the base must be level. You can provide an ideal surface by removing the old coating and pouring a new one. Although oriented strand boards are not afraid of moisture, the base needs additional waterproofing. This will protect the space under the slab from condensation and mold. After laying on the surface of roofing felt or polyethylene cleared of old screed, beacons are installed and secured with plaster. To align them, use a level, a chalk line, a tape measure and cross threads. Now more about how to level the floor using these devices:

True, the solution will dry completely 4 weeks after it is poured, but after that you can start laying the OSB panels. Installation of OSB boards on a concrete base. For their installation on a concrete base, the following is required:

Installation of OSB boards on a concrete base. For their installation on a concrete base, the following is required:

- notched trowel;

- perforator;

- dowel-nails;

- Screwdriver;

- a hammer;

- Parquet glue.

On a perfectly flat base, it is enough to lay one layer of 10-millimeter material. This is a good heat and sound insulator. The laying order is as follows.

Return to Contents</a>

Oriented chipboard under the finishing layer

Installation of a floor using OSB.If you decide to level the floor under linoleum or other rolled material using OSB, then the gaps between the boards must be rubbed down, but for this you need to use elastic compounds like sealant. Laying laminate on an OSB surface does not require any additional preparatory measures. But laying tiles requires a more rigid adhesion (tongue and groove) from the panels to each other. True, the tiles are laid on the OSB base when it is laid on joists. In addition, the OSB board is not able to provide reliable adhesion to ceramics. Another material must be laid on it, but more on that later. In general, making a gasket from oriented strand board between the screed and ceramic tiles is expensive and simply does not make sense. How to level an OSB floor on wooden joists is described below. Return to the table of contents</a>

Installation of a floor using OSB.If you decide to level the floor under linoleum or other rolled material using OSB, then the gaps between the boards must be rubbed down, but for this you need to use elastic compounds like sealant. Laying laminate on an OSB surface does not require any additional preparatory measures. But laying tiles requires a more rigid adhesion (tongue and groove) from the panels to each other. True, the tiles are laid on the OSB base when it is laid on joists. In addition, the OSB board is not able to provide reliable adhesion to ceramics. Another material must be laid on it, but more on that later. In general, making a gasket from oriented strand board between the screed and ceramic tiles is expensive and simply does not make sense. How to level an OSB floor on wooden joists is described below. Return to the table of contents</a>

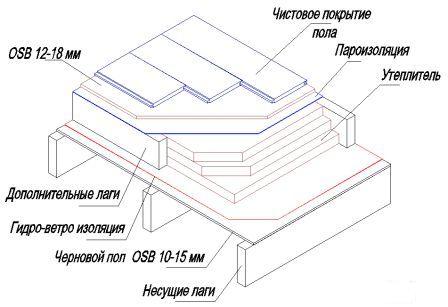

Installation of OSB-plates on logs

Installation of OSB boards on joists.For the beams, it is necessary to select the smoothest coniferous wood (pine, spruce, larch or fir). The wood moisture content should not exceed 20%. If necessary, the beams should be dried under a canopy. For small rooms, you can use logs with a cross-section of 110 x 60 mm or 150 x 80 mm. If the span in the room is more than 5 m, beams of 220 x 180 mm are used. It is desirable that whole logs are installed in the span. Joints are allowed in extreme cases. It is better to make them overlapping. On adjacent logs, the joints should be located no closer than ½ m from each other. Now about the order of work:

Installation of OSB boards on joists.For the beams, it is necessary to select the smoothest coniferous wood (pine, spruce, larch or fir). The wood moisture content should not exceed 20%. If necessary, the beams should be dried under a canopy. For small rooms, you can use logs with a cross-section of 110 x 60 mm or 150 x 80 mm. If the span in the room is more than 5 m, beams of 220 x 180 mm are used. It is desirable that whole logs are installed in the span. Joints are allowed in extreme cases. It is better to make them overlapping. On adjacent logs, the joints should be located no closer than ½ m from each other. Now about the order of work:

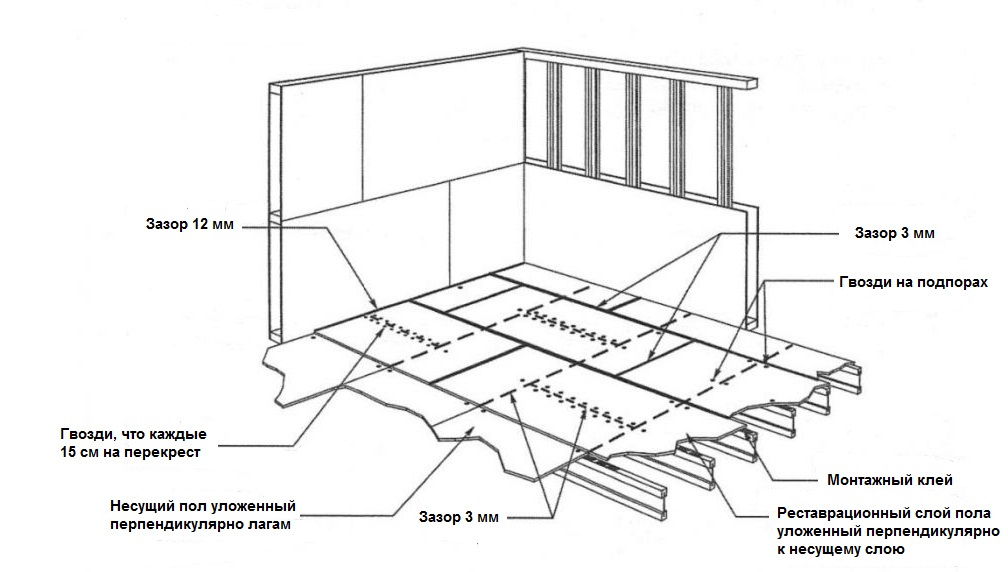

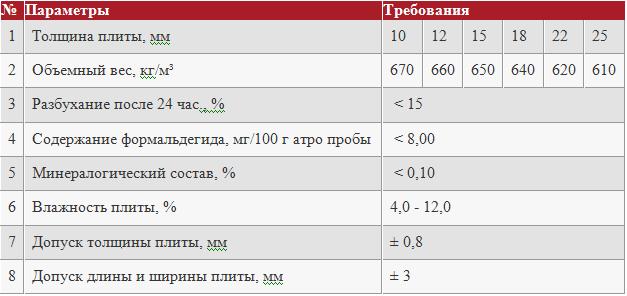

Table of characteristics of OSB boards.As a rule, 2 layers of oriented strand board are laid on the joists. The second layer is laid transversely to the first so that the joints do not coincide. The gap between the joints of the panels should be 3 mm. The gap between the wall and the OSB is 12 mm. The short edges of the boards should be joined on the support beams. The joints of the long sides should be on the supports. For better contact, the surfaces of the OSB and beams are treated with assembly glue. The boards are screwed to the joists with self-tapping screws along the short edges. The fastening step is 15 cm. Glue is applied between the upper and lower boards. Laying the upper panels is completed by screwing in self-tapping screws along the edges of each sheet. When the surface is approved on the joists, you can return to the issue of laying the tiles. OSB, although it does not provide a reliable connection with it, still serves as a solid base on which cement-bonded particle boards are laid. They are attached to the previous coating with PVA and self-tapping screws. It is desirable that the joints of the CSP do not coincide with the joints of the previous layer. It is also necessary to maintain 2-millimeter compensating gaps between adjacent boards, as well as between the CSP and the wall. After this, you can start laying the tile covering. Thus, the installation of an OSB floor and its alignment with this promising building material for subsequent finishing is not particularly difficult compared to other methods of installing flooring. It can be stated that OSB boards are not the best option when preparing a base for laying ceramic tiles, but otherwise oriented strand boards are ready for full-fledged competition with both modern and traditional building materials.

Table of characteristics of OSB boards.As a rule, 2 layers of oriented strand board are laid on the joists. The second layer is laid transversely to the first so that the joints do not coincide. The gap between the joints of the panels should be 3 mm. The gap between the wall and the OSB is 12 mm. The short edges of the boards should be joined on the support beams. The joints of the long sides should be on the supports. For better contact, the surfaces of the OSB and beams are treated with assembly glue. The boards are screwed to the joists with self-tapping screws along the short edges. The fastening step is 15 cm. Glue is applied between the upper and lower boards. Laying the upper panels is completed by screwing in self-tapping screws along the edges of each sheet. When the surface is approved on the joists, you can return to the issue of laying the tiles. OSB, although it does not provide a reliable connection with it, still serves as a solid base on which cement-bonded particle boards are laid. They are attached to the previous coating with PVA and self-tapping screws. It is desirable that the joints of the CSP do not coincide with the joints of the previous layer. It is also necessary to maintain 2-millimeter compensating gaps between adjacent boards, as well as between the CSP and the wall. After this, you can start laying the tile covering. Thus, the installation of an OSB floor and its alignment with this promising building material for subsequent finishing is not particularly difficult compared to other methods of installing flooring. It can be stated that OSB boards are not the best option when preparing a base for laying ceramic tiles, but otherwise oriented strand boards are ready for full-fledged competition with both modern and traditional building materials.