If you go into a furniture store, you'll see it in the eyesA wide range of different models of wooden furniture will be available. There are many beautiful chairs: from stools to elite models. However, such beauty requires large financial costs. Therefore, to decorate the interior of the room, you can create a wooden chair with your own hands. To make it, you need to have certain materials and tools. Wooden chair dimensions and mounting locationsscrews. There are different methods that allow you to do . When choosing a method, you need to be guided by the style, as well as its purpose. The work should begin with a drawing of the future structure, where all the dimensions of the parts, their number, and the materials needed for the work should be indicated. The success of the work depends on the quality of the drawing.

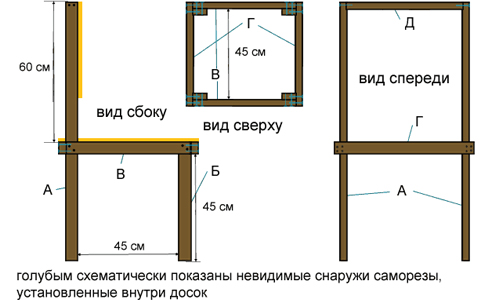

Wooden chair dimensions and mounting locationsscrews. There are different methods that allow you to do . When choosing a method, you need to be guided by the style, as well as its purpose. The work should begin with a drawing of the future structure, where all the dimensions of the parts, their number, and the materials needed for the work should be indicated. The success of the work depends on the quality of the drawing.

Necessary materials and tools

When it is necessary to make a chair usingwood with your own hands, you need to use only deciduous wood. The main material is considered to be wood that is well dried and has no knots. For the manufacture of furniture, they usually choose:

- pine;

- oak;

- beech.

It is very difficult to process oak or beech, but furniture made from such wood with your own hands turns out strong and reliable. In order to , you need to have:

- two bars;

- dense upholstery fabric;

- foam from which the seat is made;

- boards of different sizes;

- nazhdachka;

- furniture glue;

- self-tapping screws.

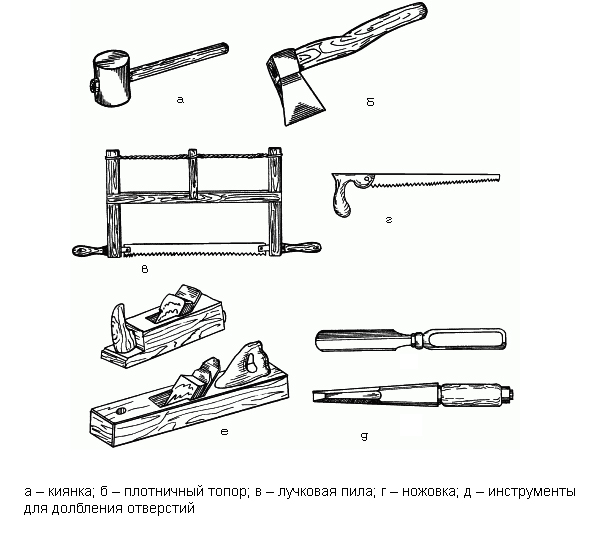

Tools for making a wooden chair.The beams can be bought at a construction market. Then they need to be processed so that they are absolutely smooth. To do this, they are sanded until roughness is obtained. First, the beam is sanded with fine sandpaper (No. 100 is suitable). The final shine of the beam will be given by sandpaper No. 220. Any work, in order to make a chair from wood with your own hands, requires the presence of tools:

Tools for making a wooden chair.The beams can be bought at a construction market. Then they need to be processed so that they are absolutely smooth. To do this, they are sanded until roughness is obtained. First, the beam is sanded with fine sandpaper (No. 100 is suitable). The final shine of the beam will be given by sandpaper No. 220. Any work, in order to make a chair from wood with your own hands, requires the presence of tools:

- nazhdachka;

- A stapler;

- hacksaw;

- conductors,

- wooden mallet;

- chisel;

- plane.

Return to Contents</a>

Technology and work features

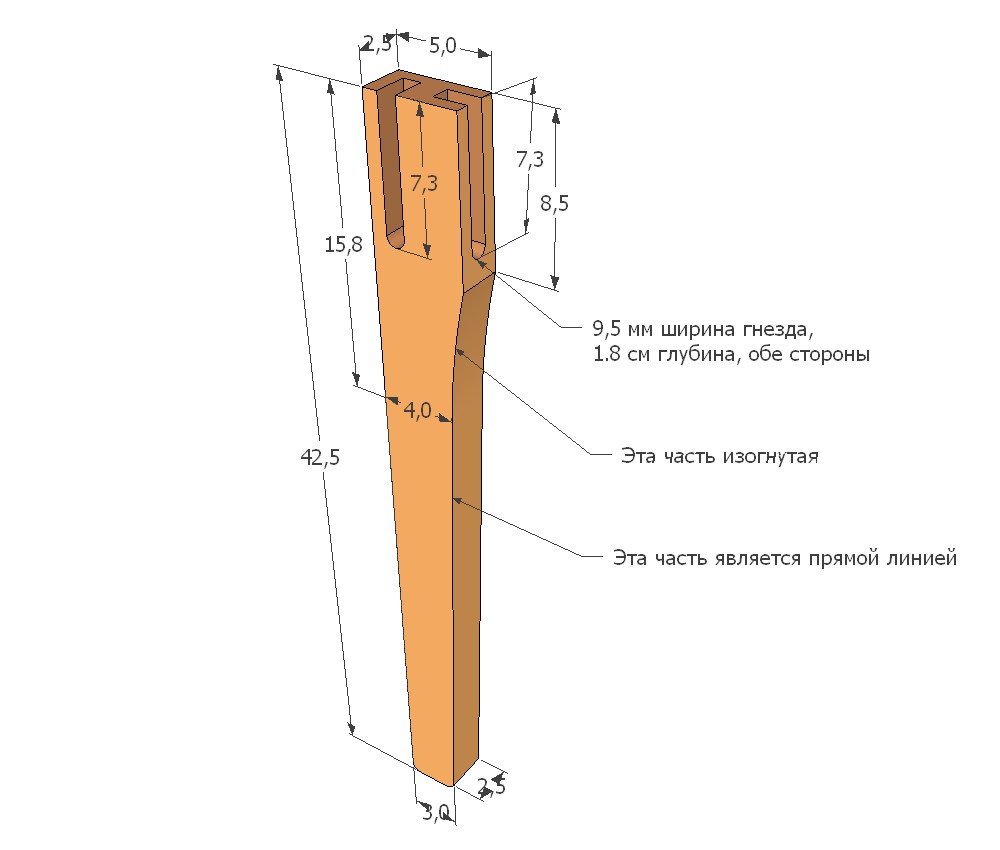

How to make a chair?First, you need to prepare two bars. The bars of the back legs should have dimensions of 800x40x60. The size of the bars of the front legs should be 440x40x40 mm. Grooves are cut in the bars for the crossbars and the base (both longitudinal and transverse). All the grooves should be made at the same level. To achieve this, they must be laid together, the ends of the legs must necessarily coincide. Then the place where the grooves will be made is marked. Their dimensions are 20x40x15 mm. The inner part of the groove should have an indent from the inner side of the leg. Usually 10 mm is taken. To attach the bases, the legs must have grooves. There should be two of them in each leg. The grooves are made at the corresponding ends of the legs. After assembly, the base will look like a rectangle. A leg will be installed on each vertex. A chisel is used to make the grooves. The grooves are then cleared of any chips that got into them during manufacturing. Chair leg diagram.The back legs need to be slightly adjusted. To do this, the edge is planed along the entire length of the leg, starting from the groove made at the top and ending with the lower groove. As a result, a smooth transition will be obtained, the size should decrease and equal 40 mm. After making the legs, two crossbars are made, two longitudinal bases are prepared. For this purpose, four bars with dimensions of 350x40x40 mm are made. Each end should have a mark for the tenons. The tenons are made with a chisel from blanks cut with a hacksaw. The sizes of the tenons should be made in accordance with the sizes of the grooves. They should fit tightly into the groove. The presence of play is prohibited. Then two bars with dimensions of 420x40x40 mm are prepared. They are needed to make the transverse base. Tenons are also cut for such bars. The next operation will be making the back. It is better to make it from edged board. The dimensions of the backrest are 420x80x100 mm. Grooves of the required width are gouged out in the rear legs. The backrest is inserted into them. The seat is fastened with self-tapping screws, and they should be screwed in from below. To make it easier to screw in the screws and give the chair additional rigidity, special braces are inserted between the bases. To give a beautiful appearance, the legs of the chair must be rounded and then carefully sanded. The same operation must be carried out with the base. Completely finished parts must be covered with furniture varnish and then polished. One of the last stages is the manufacture of a soft seat. The seat is cut out of a sheet of thick plywood, and a foam rubber blank of the appropriate shape is made in the same way. When making the chair cover, about 15 cm are retreated from the edge. Then the plywood together with the foam rubber is wrapped in furniture fabric. The material is secured with a stapler on the back side of the base.

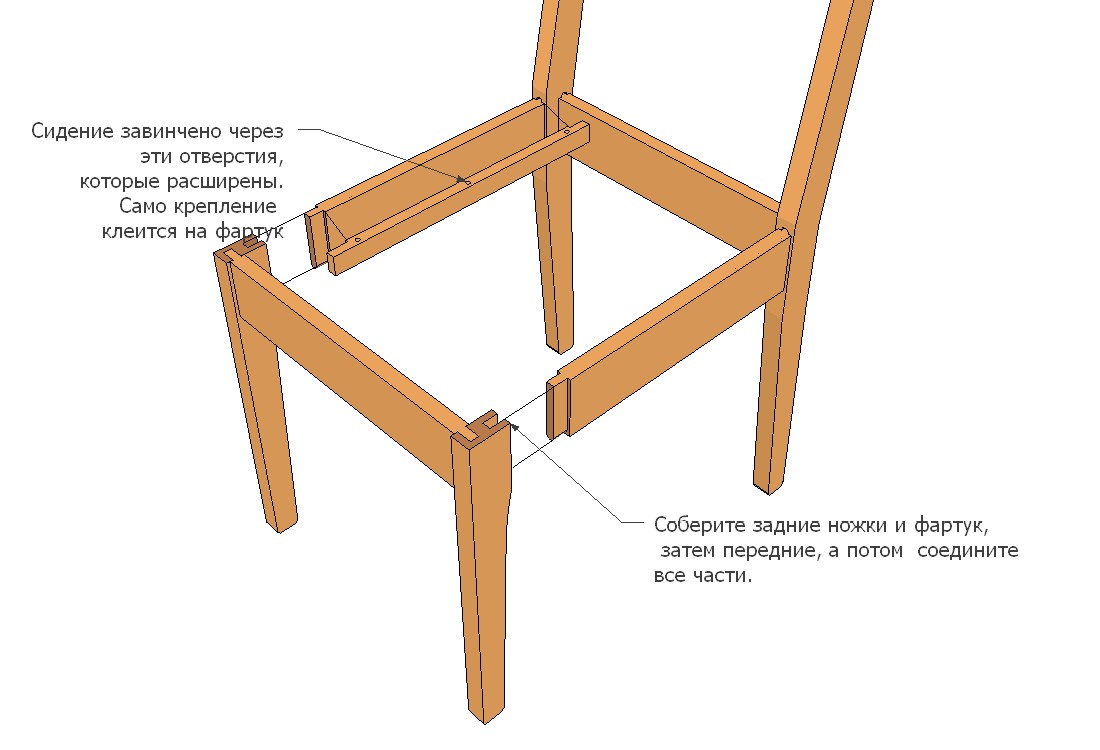

Chair leg diagram.The back legs need to be slightly adjusted. To do this, the edge is planed along the entire length of the leg, starting from the groove made at the top and ending with the lower groove. As a result, a smooth transition will be obtained, the size should decrease and equal 40 mm. After making the legs, two crossbars are made, two longitudinal bases are prepared. For this purpose, four bars with dimensions of 350x40x40 mm are made. Each end should have a mark for the tenons. The tenons are made with a chisel from blanks cut with a hacksaw. The sizes of the tenons should be made in accordance with the sizes of the grooves. They should fit tightly into the groove. The presence of play is prohibited. Then two bars with dimensions of 420x40x40 mm are prepared. They are needed to make the transverse base. Tenons are also cut for such bars. The next operation will be making the back. It is better to make it from edged board. The dimensions of the backrest are 420x80x100 mm. Grooves of the required width are gouged out in the rear legs. The backrest is inserted into them. The seat is fastened with self-tapping screws, and they should be screwed in from below. To make it easier to screw in the screws and give the chair additional rigidity, special braces are inserted between the bases. To give a beautiful appearance, the legs of the chair must be rounded and then carefully sanded. The same operation must be carried out with the base. Completely finished parts must be covered with furniture varnish and then polished. One of the last stages is the manufacture of a soft seat. The seat is cut out of a sheet of thick plywood, and a foam rubber blank of the appropriate shape is made in the same way. When making the chair cover, about 15 cm are retreated from the edge. Then the plywood together with the foam rubber is wrapped in furniture fabric. The material is secured with a stapler on the back side of the base. Chair assembly diagram.Experience shows that when making a wooden chair with your own hands, you must always remember about the surroundings. The fact is that varnish coating causes a very strong unpleasant smell. The neighbors will clearly not be delighted. Therefore, it is best to do all painting work outside the apartment. For example, in a garage or a shed. Recently, special varnishes have appeared that are based on water. They are odorless. The chair is assembled from the prepared varnished parts. The spikes are covered with glue and inserted into the grooves. All the parts are knocked down with a wooden mallet. If you use a metal hammer, then its striking part must be covered with a soft cloth. Otherwise, you can damage the varnish coating. The seat and back are fastened with screws. Return to the table of contents</a>

Chair assembly diagram.Experience shows that when making a wooden chair with your own hands, you must always remember about the surroundings. The fact is that varnish coating causes a very strong unpleasant smell. The neighbors will clearly not be delighted. Therefore, it is best to do all painting work outside the apartment. For example, in a garage or a shed. Recently, special varnishes have appeared that are based on water. They are odorless. The chair is assembled from the prepared varnished parts. The spikes are covered with glue and inserted into the grooves. All the parts are knocked down with a wooden mallet. If you use a metal hammer, then its striking part must be covered with a soft cloth. Otherwise, you can damage the varnish coating. The seat and back are fastened with screws. Return to the table of contents</a>

Folding chairs: nuances of manufacture

Make a folding chair from wood with your own handsany craftsman can do it. It will take much less time than making an ordinary stool. You will need to stock up on wood for the job. The front legs and back are made of a shield. These parts will be able to move. The back legs are made of wooden blocks. Thin slats are nailed to the back. Plywood covered with thick furniture fabric can be used as a seat material. To be able to fix the product in the desired position, it is necessary to make several spikes on the shield. Steel pins will come in handy for fastening the base. To fix the seat horizontally and install the shield at an angle, you need to make spikes. The seat is fixed with two steel pins. Return to contents</a>

Braided stool: recommendations

The production of a wicker chair is not particularly difficult. To do the job, you need to have:

- braid;

- nails;

- beams;

- hacksaw;

- self-tapping screws;

- a hammer;

- Danish oil;

- drill;

- sandpaper.

The length of the legs is measured.Four bars measuring 18x4x14 cm are prepared. Grooves are made in the places where the connection and fastening will take place. To make the bars smooth, they are sanded with sandpaper. Then the wicker chair is assembled. Assembly work begins with fastening the legs. Screws are screwed in. Danish oil is applied to the assembled frame. If it is not available, furniture varnish can be used as a substitute. The final operation will be weaving with belts. Usually, long straps made of leather are used for this purpose.