The range of furniture on the market is so wide that,It would seem that there is no point in “reinventing the wheel” and making it yourself when you can either buy a ready-made version or order it from companies that have professional equipment for an individual project, for every taste and budget. But this is just a boring life template. A creative person who loves his home or summer house very much will always find the time and opportunity to make furniture with his own hands that is not only no worse than the one he bought, but also exclusive. You can make any cabinet furniture, chairs, cabinets, tables, armchairs with your own hands, and the most suitable material for this is plywood. If the reader considers himself to be a “Beginner” in this matter, then it is worth starting with the simplest thing - making a plywood chair with your own hands. Plywood for making a chair needs to be selected1 or 2 grades, 7-25 cm thick. Plywood is layers of sheets of different wood glued together perpendicularly (this is the arrangement that makes plywood very strong) to each other, with a thickness of seven to twenty-five millimeters. Its application is very wide, thicker sheets are used for laying subflooring, erecting partitions in the house. Plywood up to ten millimeters thick is used to cover walls. It is better to make furniture at home from plywood ten millimeters thick, it is strong and elastic enough, in case it needs to be bent for a decorative element.

Plywood for making a chair needs to be selected1 or 2 grades, 7-25 cm thick. Plywood is layers of sheets of different wood glued together perpendicularly (this is the arrangement that makes plywood very strong) to each other, with a thickness of seven to twenty-five millimeters. Its application is very wide, thicker sheets are used for laying subflooring, erecting partitions in the house. Plywood up to ten millimeters thick is used to cover walls. It is better to make furniture at home from plywood ten millimeters thick, it is strong and elastic enough, in case it needs to be bent for a decorative element.

Tools and materials for the manufacture of stools

Tools for working with plywood: saw or jigsaw, tape measure, square, pencil.

Tools for working with plywood: saw or jigsaw, tape measure, square, pencil.

- 15mm thick plywood - 1 sheet;

- a beam for legs in the size 40 х 60 mm, 2 pieces on 3 m;

- foam rubber with a thickness of 70 mm, measuring 500 x 500 mm;

- decorative upholstery - furniture fabric or leatherette, 600 x 600 mm.

The timber must be dried and sanded.It is better to choose plywood from birch, as it is stronger than other types, easy to process and optimal for painting or finishing in any other way. The tools that may be needed are usually available to any owner. This is a chisel, a jigsaw, a screwdriver, a grinder or sandpaper, a stapler with staples and a hammer. You need to get some screws and furniture glue. It is good if you have a jig for assembling furniture. It will allow you to accurately drill holes for fasteners, due to which the chair will be assembled as professionally as possible. Return to the table of contents</a>

Preparatory stage: nuances

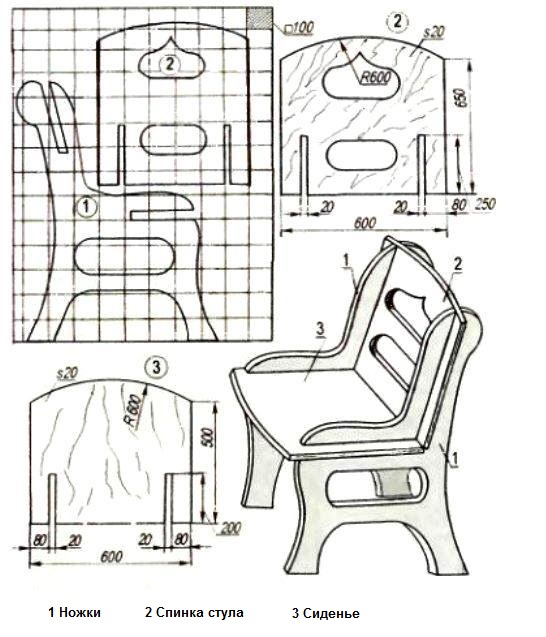

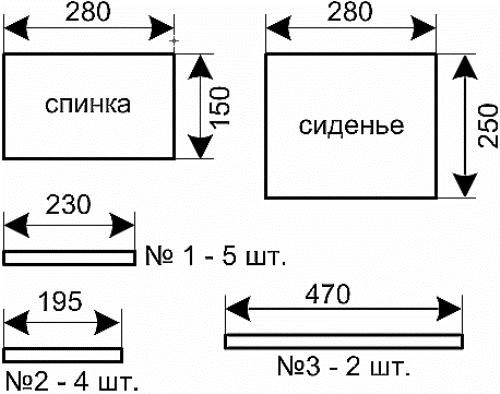

Drawing of a folding plywood chair with dimensions.Where to start? On a sheet of paper 1 x 1 m (Whatman paper) you need to draw in 1:1 scale the parts from which the chair will be assembled. Cut them out. The selected model of the chair consists of the following parts:

Drawing of a folding plywood chair with dimensions.Where to start? On a sheet of paper 1 x 1 m (Whatman paper) you need to draw in 1:1 scale the parts from which the chair will be assembled. Cut them out. The selected model of the chair consists of the following parts:

- rear leg height 800 mm - two pieces;

- front leg height 440 mm - two pieces;

- slats for strengthening the structure of the chair, 400 mm long (side bars) - four pieces;

- seat size 360 x 400 mm - 1 piece.

- slats for reinforcing the seat structure: 400 mm - 2 pieces, 280 mm - 2 pieces.

- chair back measuring 300 x 450 mm - one piece.

Return to Contents</a>

Features of the manufacture of parts

Cut two 800mm beams for the rear legs.chair. At a distance of 200 mm from the base of the leg, cut out holes for the fastening strips (sidebars). To do this, fold the legs in a row and outline the boundaries of the grooves. Gouge holes on two adjacent sides of the chair legs using a chisel and hammer measuring 20x40 mm and to a depth of 15-20 mm strictly in the middle of the bar. It should turn out so that on the side of the bar at 60 mm the hole is located horizontally, and at 40 mm - vertically. Clean them thoroughly from wood dust. If this is not done, the strips will not fit securely into the grooves. To make the front legs, saw off two bars of 440 mm. At a distance of 200 mm from the base, similarly as on the back legs, make holes for the strips. Layout of chair parts on a sheet of plywood.Measure 15 mm from the top of the front legs and use a chisel and a saw to cut out 20 x 40 mm tenons for attaching to the base of the chair seat. The planks that give the chair strength should be made from timber. Cut off 4 pieces 380 mm long. Measure 10 mm on both sides and cut out tenons using a saw and a chisel, which will be inserted into the grooves of the legs when assembling the chair. This must be done with maximum precision so that the tenons enter the grooves only with force using a hammer. Despite the fact that sanded timber was chosen for making the chair, the manufactured legs and planks should be processed with sandpaper, since burrs could have formed during the work. Cut out the back using an electric jigsaw. To do this, draw the details on the plywood using paper templates prepared in advance. The jigsaw should be used smoothly, then sanded on all sides, thereby smoothing out any unevenness. Of course, you can make a simple chair without bending, but a chair with a curved back looks much more aesthetically pleasing, and it is more comfortable to sit on. In order to bend the back, you must first steam or soak it. The steaming process at home can be very difficult, since it is difficult to find a suitable container and steam it for several hours. A good alternative is soaking in warm water. Place the part in water at a temperature of 50-60 degrees and wait for 3-4 hours. After that, give the back the desired shape and fix it with a tourniquet until completely dry.

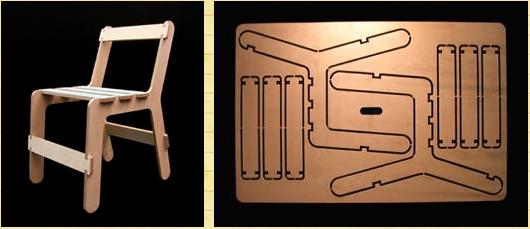

Layout of chair parts on a sheet of plywood.Measure 15 mm from the top of the front legs and use a chisel and a saw to cut out 20 x 40 mm tenons for attaching to the base of the chair seat. The planks that give the chair strength should be made from timber. Cut off 4 pieces 380 mm long. Measure 10 mm on both sides and cut out tenons using a saw and a chisel, which will be inserted into the grooves of the legs when assembling the chair. This must be done with maximum precision so that the tenons enter the grooves only with force using a hammer. Despite the fact that sanded timber was chosen for making the chair, the manufactured legs and planks should be processed with sandpaper, since burrs could have formed during the work. Cut out the back using an electric jigsaw. To do this, draw the details on the plywood using paper templates prepared in advance. The jigsaw should be used smoothly, then sanded on all sides, thereby smoothing out any unevenness. Of course, you can make a simple chair without bending, but a chair with a curved back looks much more aesthetically pleasing, and it is more comfortable to sit on. In order to bend the back, you must first steam or soak it. The steaming process at home can be very difficult, since it is difficult to find a suitable container and steam it for several hours. A good alternative is soaking in warm water. Place the part in water at a temperature of 50-60 degrees and wait for 3-4 hours. After that, give the back the desired shape and fix it with a tourniquet until completely dry. Before you start assembling the chair, you need tocut out all the details. There is another way to bend plywood. It can be used for plywood with a thickness of 15 mm. To do this, make cuts at the bend so that they do not reach the opposite side by 30%. The greater the bend angle, the more often the cuts need to be made. Bend the plywood sheet, fix it in the desired position and glue the thin veneer, then let it dry. This bending method is more labor-intensive and requires professional skills. Of all the three methods of bending plywood, it is recommended to choose the soaking in warm water method. Cut a seat out of plywood using a paper pattern. Prepare 2 planks of 400 mm and 2 planks of 320 mm from a bar to strengthen the structure of the chair. Cut tenons measuring 20 x 40 mm at both ends of the larger ones and 20 x 40 mm on the other two. grooves measuring 20 x 40 mm, stepping back from the edge by 10 mm. The finished parts should be processed with sandpaper. Before starting to assemble the chair, all parts should be varnished with any color and wait until completely dry. Return to contents</a>

Before you start assembling the chair, you need tocut out all the details. There is another way to bend plywood. It can be used for plywood with a thickness of 15 mm. To do this, make cuts at the bend so that they do not reach the opposite side by 30%. The greater the bend angle, the more often the cuts need to be made. Bend the plywood sheet, fix it in the desired position and glue the thin veneer, then let it dry. This bending method is more labor-intensive and requires professional skills. Of all the three methods of bending plywood, it is recommended to choose the soaking in warm water method. Cut a seat out of plywood using a paper pattern. Prepare 2 planks of 400 mm and 2 planks of 320 mm from a bar to strengthen the structure of the chair. Cut tenons measuring 20 x 40 mm at both ends of the larger ones and 20 x 40 mm on the other two. grooves measuring 20 x 40 mm, stepping back from the edge by 10 mm. The finished parts should be processed with sandpaper. Before starting to assemble the chair, all parts should be varnished with any color and wait until completely dry. Return to contents</a>

Chair assembly: recommendations

Details and dimensions of a plywood chair.First, you need to assemble the base, which consists of 4 legs and planks to strengthen the structure. Having pre-treated the tenons on the planks with furniture glue (or any glue that is suitable for gluing wooden surfaces), insert them into the grooves on the legs. It is considered that the parts are cut correctly if this process required effort. Next, you need to assemble the frame for the seat from the 4 remaining planks, also pre-lubricating the tenons with glue. Also coat the base of the seat with glue along the edges and fasten it to the frame. You can strengthen the structure with self-tapping screws. Cut the foam rubber to the size of the seat. Glue it to the base of the chair. Cut a cover from fabric or leatherette. Using a furniture stapler, fasten the fabric to the lower sides of the chair frame, carefully tucking the edges so that the grooves are free. The seat is ready. Treat the tenons of the front legs with glue and insert them into the grooves. The back legs are fastened to the seat with screws screwed into the end of the frame. The back of the chair can also be made soft, similar to the seat, or left unchanged. It's a matter of taste. The back of the chair is attached to the upper part of the back legs with screws. Is it possible to make it at home from plywood? Yes. If you carefully approach the choice of high-quality materials. Don't be lazy and draw out the parts of the chair on paper. Measure all the dimensions to the millimeter. Before assembly, process all the parts with sandpaper and varnish. And finally, show a little design skills and choose a beautiful fabric for the upholstery of the chair. As a result, you will get a comfortable, exclusive chair with minimal costs for its manufacture.</ ul>

Details and dimensions of a plywood chair.First, you need to assemble the base, which consists of 4 legs and planks to strengthen the structure. Having pre-treated the tenons on the planks with furniture glue (or any glue that is suitable for gluing wooden surfaces), insert them into the grooves on the legs. It is considered that the parts are cut correctly if this process required effort. Next, you need to assemble the frame for the seat from the 4 remaining planks, also pre-lubricating the tenons with glue. Also coat the base of the seat with glue along the edges and fasten it to the frame. You can strengthen the structure with self-tapping screws. Cut the foam rubber to the size of the seat. Glue it to the base of the chair. Cut a cover from fabric or leatherette. Using a furniture stapler, fasten the fabric to the lower sides of the chair frame, carefully tucking the edges so that the grooves are free. The seat is ready. Treat the tenons of the front legs with glue and insert them into the grooves. The back legs are fastened to the seat with screws screwed into the end of the frame. The back of the chair can also be made soft, similar to the seat, or left unchanged. It's a matter of taste. The back of the chair is attached to the upper part of the back legs with screws. Is it possible to make it at home from plywood? Yes. If you carefully approach the choice of high-quality materials. Don't be lazy and draw out the parts of the chair on paper. Measure all the dimensions to the millimeter. Before assembly, process all the parts with sandpaper and varnish. And finally, show a little design skills and choose a beautiful fabric for the upholstery of the chair. As a result, you will get a comfortable, exclusive chair with minimal costs for its manufacture.</ ul>