Decorating walls covered with plasterboard,It is possible not only by finishing its surface, but also by complementing the structure with various design elements made of the same material. Plasterboard as a finishing material does not have aesthetic qualities, but structures made from it allow you to implement various design solutions and improve the functionality of the room. Plasterboard structures are lightweight anddo not load the interfloor ceilings. With the help of partitions, niches, shelves made of plasterboard, you can completely change the geometry of wall structures. The arrangement of arches, semi-arches and other curvilinear elements blurs the boundaries between the wall and the ceiling. At the same time, the decorative ensemble can be either monochrome or with different coloring of elements and harmonious color transitions.

Plasterboard structures are lightweight anddo not load the interfloor ceilings. With the help of partitions, niches, shelves made of plasterboard, you can completely change the geometry of wall structures. The arrangement of arches, semi-arches and other curvilinear elements blurs the boundaries between the wall and the ceiling. At the same time, the decorative ensemble can be either monochrome or with different coloring of elements and harmonious color transitions.

Features of using drywall for decoration

Plasterboard (dry plaster) is mounted toconcrete, brick, block walls by direct fastening or using a frame made of wooden lathing or metal profiles. Finishing and decorating walls with plasterboard in comparison with using other materials for decorating a room has the following advantages: If a metal frame is not used when installing a plasterboard niche, the internal volume of the niche will increase by 2-5 cm.

If a metal frame is not used when installing a plasterboard niche, the internal volume of the niche will increase by 2-5 cm.

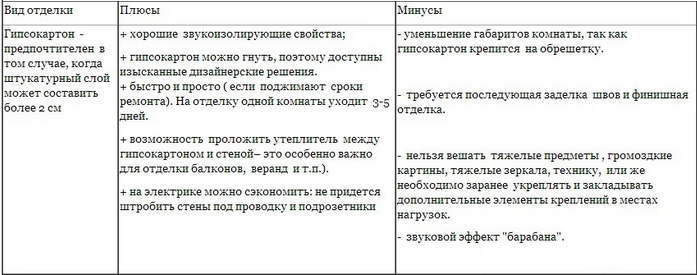

Pros and cons of finishing walls with plasterboard.The load-bearing capacity of walls covered with plasterboard using standard technology is quite low. Massive decorative elements (wall cabinets, mirrors, shelves for household appliances) are mounted on a frame reinforced with additional metal elements. Return to contents</a>

Pros and cons of finishing walls with plasterboard.The load-bearing capacity of walls covered with plasterboard using standard technology is quite low. Massive decorative elements (wall cabinets, mirrors, shelves for household appliances) are mounted on a frame reinforced with additional metal elements. Return to contents</a>

Types of structures to be mounted using plasterboard

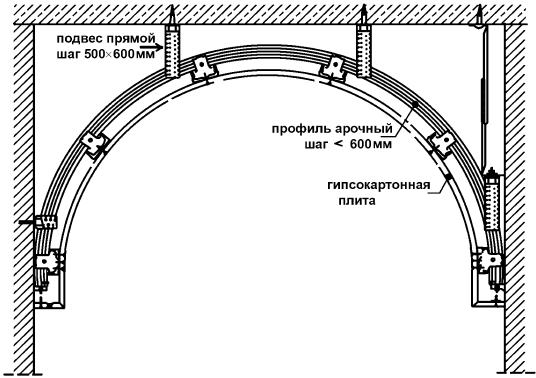

Plasterboards are mounted on the wallsdecorative structures of various shapes, sizes, functional capabilities, using original design solutions. Decorating with plasterboard sheets is often one of the stages of implementing a housing design project. The design project for wall decoration is first created on paper in the form of a drawing or sketch. Detailing of complex plasterboard structures can be developed using computer programs. Various techniques are used to decorate partitions and walls made of plasterboard: Installation diagram of a plasterboard arch.

Installation diagram of a plasterboard arch.

- Form niches, wall and corner shelves;

- built-in slides, wardrobes;

- The openings are equipped with arched elements;

- additional relief surfaces are mounted;

- Rounding of ends and angular matings is carried out;

- illumination of constructions is arranged, etc.

When making wall decoration elementsThe purpose of the room is taken into account. The bedroom design uses simple relief structures without cluttering them with unnecessary recesses and volumetric assemblies. A large corridor can be equipped with full-fledged niches and shelves for clothes, shoes and other items. In kitchens, niches are sometimes equipped with sliding systems or lightweight doors made of MDF, chipboard, etc. The structure of plasterboard does not allow the use of hanging hinged elements with a high operational load in structures. Furniture made of gypsum board is a kind of continuation of the wall and is made according to standard technological principles. Suitable furniture facades and fittings are used. To arrange the shelves, a profile frame is created, reinforced with load-bearing CD profiles. The difference from the installation of the base surface is the sheathing with material on both sides and, accordingly, the installation of load-bearing profiles in opposite directions. The frame of the corner shelves is formed with a base in the form of a triangle. The decoration of plasterboard walls is also carried out in combination with other decorative materials. Mirrors, glass elements, special fabrics, mosaics, etc. are used in the constructions. Return to the table of contents</a>

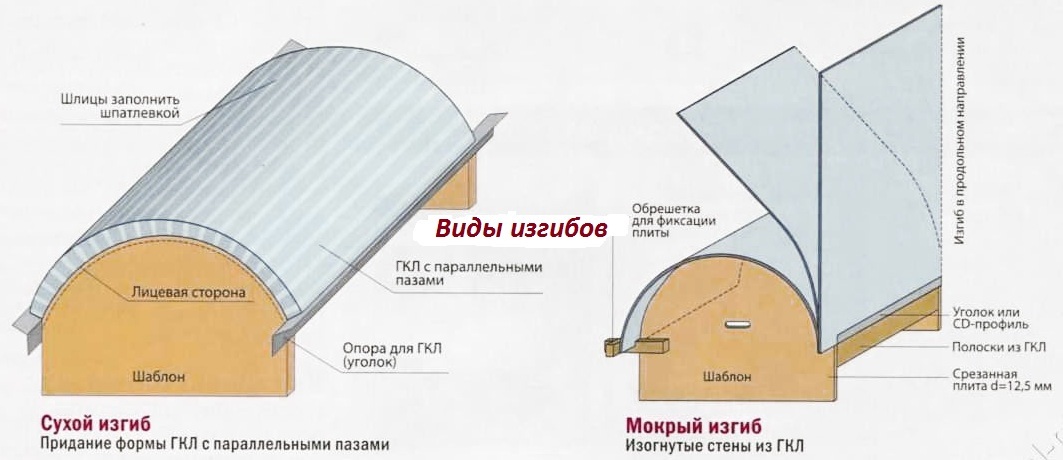

Curved surfaces of plasterboard

Types of gypsum board bending: dry and wet.Radius surfaces are used in the connection of walls with ceilings, arched structures of door and window openings, when forming niche decor. It is not always possible to purchase bent plasterboard structures ready-made, and it is necessary to bend the sheets using improvised means. The manufacture of curved wall decor elements requires special skills, and it is better to entrust it to experienced specialists. The following methods are used to bend the material along a given radius:

Types of gypsum board bending: dry and wet.Radius surfaces are used in the connection of walls with ceilings, arched structures of door and window openings, when forming niche decor. It is not always possible to purchase bent plasterboard structures ready-made, and it is necessary to bend the sheets using improvised means. The manufacture of curved wall decor elements requires special skills, and it is better to entrust it to experienced specialists. The following methods are used to bend the material along a given radius:

- bending of dry sheets with a radius of 1 m;

- rounding of moistened elements using a needle roller;

- making cuts on the stretchable surface of a sheet of small size.

For wet processing are usednon-moisture-resistant plasterboard sheets. When using the "wet" method, the surface of the sheet subject to compression is pierced with a needle roller and moistened. In the concave surface, the cardboard is pierced from the front side, in convex elements - from the back. The bending element of the structure is moistened with water until completely moistened and fixed with masking tape on a template of the desired diameter. Pipes or wooden circles used for laying brick arches are used as such. The bend is performed only along the web, which is kept on the template until completely dry. Installation of curvilinear elements is carried out with self-tapping screws on a frame fastened from profile segments, or a profile bent due to shelf cuts. Bent structures are mounted after drying and taking the desired shape. It is more practical to purchase ready-made elements that have undergone additional processing for creating wall decor from plasterboard. It is not worth using a large number of decorations for wall structures of small rooms. An interior saturated with design elements makes the perception of the room heavier.</ ul>