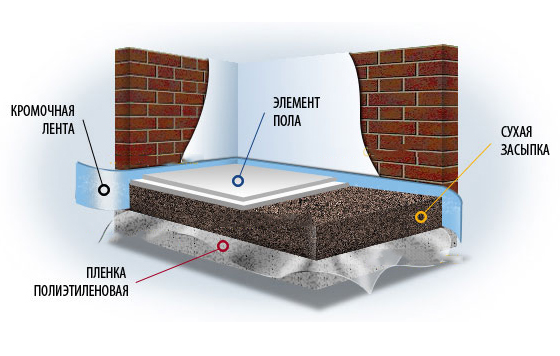

There are many reasons why this happensimpossible to carry out a conventional cement floor screed. This is a limited time frame for preparing the base for a decorative floor covering, unfavorable climatic conditions of the room for the full drying of the wet concrete layer or the need to have constant access to the laid communications. But we must not forget that the ability to give the floor an ideal flatness with minimal costs and in a short time using a dry screed has its own characteristics. Dry floor screed diagram.

Dry floor screed diagram.

Features of dry floor screed

There are two types of floor screed:made of wet cement-sand mortar or prefabricated, also called dry. The latter method is considered much more economical and therefore is becoming increasingly widespread in construction and repair work. Another reason for its popularity was the relative simplicity of the device of a dry floor screed, which does not require complex preparatory operations and high professionalism of the craftsmen. The base is leveled using loose materials of a small fraction. Usually, expanded clay or perlite expanded sand is used for this purpose. Subsequent ramming allows you to compact the backfill, making it perfectly flat, and the coating with gypsum fiber sheets creates a stable and durable rough floor base. Return to contents</a>

Disadvantages of floor screed, carried out by dry method

Floor screed laying scheme.The disadvantages of using dry screed are fewer than the advantages it has. Despite this fact, the disadvantages of this means of leveling the base are quite serious. Before making a final decision on the use of this method, it is necessary to take into account all the factors that can subsequently affect the quality and durability of the base. The main disadvantage of dry screed is the need to avoid any contact with moisture. In rooms such as the kitchen and bathroom, its installation is contraindicated, since the penetration of water into the thickness of the backfill will inevitably lead to the formation of mold and mildew, which can only be eliminated by completely dismantling and replacing the base. For the same reason, it becomes impossible to install a water-heated floor system - the slightest leak will cause irreparable damage to the base. Even the installation of reinforced waterproofing will not protect the backfill layer and gypsum fiber board from water penetration. It is better to carry out dry screed installation work in dry and warm weather so that the expanded clay or sand mixture does not absorb moisture. Dry screed cannot be used to level floors in rooms without heating and with high humidity. Basements, ground floors and other similar places are not suitable for its use.

Floor screed laying scheme.The disadvantages of using dry screed are fewer than the advantages it has. Despite this fact, the disadvantages of this means of leveling the base are quite serious. Before making a final decision on the use of this method, it is necessary to take into account all the factors that can subsequently affect the quality and durability of the base. The main disadvantage of dry screed is the need to avoid any contact with moisture. In rooms such as the kitchen and bathroom, its installation is contraindicated, since the penetration of water into the thickness of the backfill will inevitably lead to the formation of mold and mildew, which can only be eliminated by completely dismantling and replacing the base. For the same reason, it becomes impossible to install a water-heated floor system - the slightest leak will cause irreparable damage to the base. Even the installation of reinforced waterproofing will not protect the backfill layer and gypsum fiber board from water penetration. It is better to carry out dry screed installation work in dry and warm weather so that the expanded clay or sand mixture does not absorb moisture. Dry screed cannot be used to level floors in rooms without heating and with high humidity. Basements, ground floors and other similar places are not suitable for its use. Tools for dry floor screed.Dry screed has a rather soft base and does not tolerate mechanical stress well. Plasterboard covering does not withstand constant physical pressure on the surface in crowded places, so dry screed is more suitable for residential premises. The main criterion for the strength of this method is good quality of compaction of the dry mixture. Violation of the technology of this process can lead to low stability of the base. Fine-grained filler is a loose and rather unstable material. Its uneven shrinkage can lead to changes in the surface level and the appearance of bends in the decorative floor covering. All this will contribute to the violation of its integrity and rapid wear of the floor. It is not recommended to subject the floor surface, the basis of which is dry loose screed, to any increased physical pressure. This applies to the installation of massive partitions made of slabs, blocks or bricks. They can press through the base with their weight, which will serve as a reason for unscheduled repairs. The same applies to heavy furniture. In rooms with low ceilings, it should be taken into account that a large layer of dry backfill will significantly reduce the height of the room. Before deciding on the choice of floor leveling method, it is worth making the necessary calculations and measurements so as not to subsequently encounter a significant deterioration in the interior and a decrease in the free space of the room. Another negative aspect of the dry method of screeding is the rustling of expanded clay when moving along the floor at first after the end of the work. This effect will stop after the complete shrinkage of the backfill level, but for some time you will have to put up with the unpleasant sound. The reproduction of insects and rodents in the dry mixture layer is also a weak point of the dry method. Therefore, when using it in private homes, you will have to carry out regular disinsection and deratization to get rid of dangerous rodents and pests.

Tools for dry floor screed.Dry screed has a rather soft base and does not tolerate mechanical stress well. Plasterboard covering does not withstand constant physical pressure on the surface in crowded places, so dry screed is more suitable for residential premises. The main criterion for the strength of this method is good quality of compaction of the dry mixture. Violation of the technology of this process can lead to low stability of the base. Fine-grained filler is a loose and rather unstable material. Its uneven shrinkage can lead to changes in the surface level and the appearance of bends in the decorative floor covering. All this will contribute to the violation of its integrity and rapid wear of the floor. It is not recommended to subject the floor surface, the basis of which is dry loose screed, to any increased physical pressure. This applies to the installation of massive partitions made of slabs, blocks or bricks. They can press through the base with their weight, which will serve as a reason for unscheduled repairs. The same applies to heavy furniture. In rooms with low ceilings, it should be taken into account that a large layer of dry backfill will significantly reduce the height of the room. Before deciding on the choice of floor leveling method, it is worth making the necessary calculations and measurements so as not to subsequently encounter a significant deterioration in the interior and a decrease in the free space of the room. Another negative aspect of the dry method of screeding is the rustling of expanded clay when moving along the floor at first after the end of the work. This effect will stop after the complete shrinkage of the backfill level, but for some time you will have to put up with the unpleasant sound. The reproduction of insects and rodents in the dry mixture layer is also a weak point of the dry method. Therefore, when using it in private homes, you will have to carry out regular disinsection and deratization to get rid of dangerous rodents and pests.