One of the most durable, reliable and inexpensiveoptions for flooring is the use of concrete screed. Due to the advantages of this coating, many people choose concrete screed for flooring in a house or garage, and therefore they often have a question: how to do it yourself? Floor screeding with concrete mixture is the highest quality and most durable option.

Floor screeding with concrete mixture is the highest quality and most durable option.

Preparatory work

For pouring concrete floors with your own handsconcrete is used, for the preparation of which cement grade M 75 and higher was used. Such a coating is laid on a cushion of crushed stone, its fraction should not exceed 15 mm, it is often used to create a warm floor in the house. Structural diagram of a concrete floor.The question of how to pour concrete scares many people, but there is nothing complicated in this process. You will just have to put in significant physical effort, and the entire technology of the work comes down to the correct preparation of the solution and the installation of beacons. At the first stage of the work, the floor must be cleared of the old coating. If the quality of the old screed is normal, then the new screed can be laid on top without removing the old coating. To remove the old concrete coating that has begun to crumble, you can use a hammer drill or a jackhammer. Before pouring the floor with mortar, it is necessary to determine the highest point of the floor in the room, for which you will have to use a water level or a level. There are cases when there is a very large difference in height between rooms, and then, in order to lay a concrete warm floor, they choose the option when it is done in each room separately. Although with this method, there will be differences in the height of the floor between the rooms, but they can be hidden with the help of decor, but the screed layer will not be too thick, the warm floor will work effectively and will not be subject to very high loads. Return to the table of contents</a>

Structural diagram of a concrete floor.The question of how to pour concrete scares many people, but there is nothing complicated in this process. You will just have to put in significant physical effort, and the entire technology of the work comes down to the correct preparation of the solution and the installation of beacons. At the first stage of the work, the floor must be cleared of the old coating. If the quality of the old screed is normal, then the new screed can be laid on top without removing the old coating. To remove the old concrete coating that has begun to crumble, you can use a hammer drill or a jackhammer. Before pouring the floor with mortar, it is necessary to determine the highest point of the floor in the room, for which you will have to use a water level or a level. There are cases when there is a very large difference in height between rooms, and then, in order to lay a concrete warm floor, they choose the option when it is done in each room separately. Although with this method, there will be differences in the height of the floor between the rooms, but they can be hidden with the help of decor, but the screed layer will not be too thick, the warm floor will work effectively and will not be subject to very high loads. Return to the table of contents</a>

Proper use of beacons

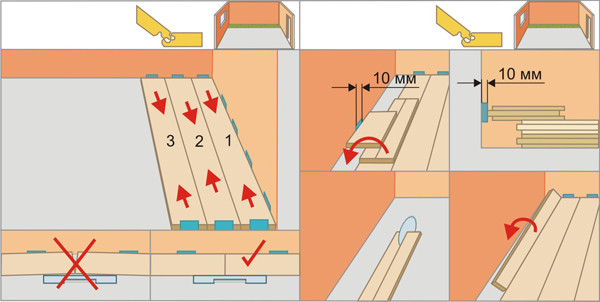

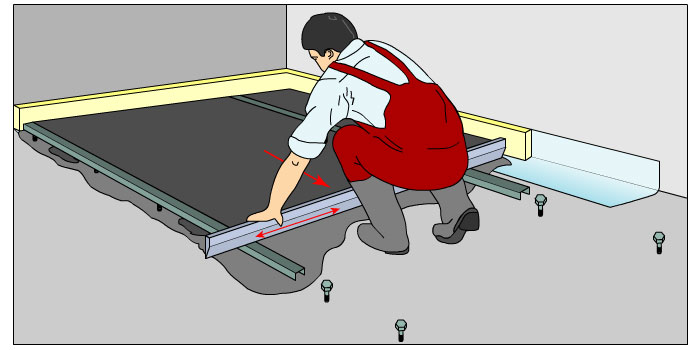

Scheme of beacon placement.The work starts from the highest point. Special T-shaped guides are best suited for making beacons, but if they are not available, other materials can be used, while wooden beacons can be used only in extreme cases. In order for the screed to have sufficient strength, its minimum thickness must be more than 7 mm. Beacons are placed on the floor surface in the form of sections, but the dimensions of these sections should not be greater than the length of the rule that will be used during the work. To align the beacons, a lining material is used. The distance between the linings should not be more than 30 cm, a building level is used to control the position of the beacon. To fix the beacons, you need to use the material from which the screed will be made, but most often they use alabaster, since it quickly sets and fixes the beacons in the desired position. It is clear that pouring a floor with concrete is a wet process, so chipboard or cardboard cannot be used as a lining material, since they can change shape under the influence of moisture, as a result of which the beacons will shift. For linings, it is best to use metal or plastic plates. Return to Contents</a>

Scheme of beacon placement.The work starts from the highest point. Special T-shaped guides are best suited for making beacons, but if they are not available, other materials can be used, while wooden beacons can be used only in extreme cases. In order for the screed to have sufficient strength, its minimum thickness must be more than 7 mm. Beacons are placed on the floor surface in the form of sections, but the dimensions of these sections should not be greater than the length of the rule that will be used during the work. To align the beacons, a lining material is used. The distance between the linings should not be more than 30 cm, a building level is used to control the position of the beacon. To fix the beacons, you need to use the material from which the screed will be made, but most often they use alabaster, since it quickly sets and fixes the beacons in the desired position. It is clear that pouring a floor with concrete is a wet process, so chipboard or cardboard cannot be used as a lining material, since they can change shape under the influence of moisture, as a result of which the beacons will shift. For linings, it is best to use metal or plastic plates. Return to Contents</a>

Preparation of the floor surface

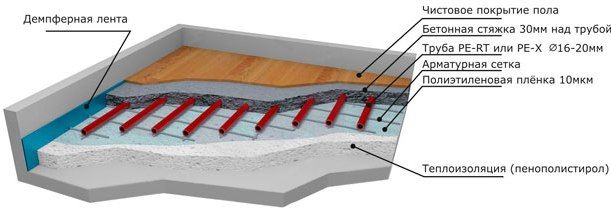

Tools and materials for carrying out work: Scheme of filling a warm floor with concrete.

Scheme of filling a warm floor with concrete.

- perforator;

- jackhammer;

- water level

- level;

- rule;

- building level;

- mixer;

- cement

- sand;

- plasticizer.

Before pouring the heated floor, it is necessarylay pipes or cables. If you are just making a concrete screed, then the floor surface is wetted with water, you can use a roller for this, otherwise the concrete will peel off. Inspect the room, and if there are gaps between the floor and the wall, they need to be filled, for this, use mounting foam. To make the solution, use cement and sand in a ratio of 1:3, after which they are mixed until a homogeneous mass is obtained. To make the solution homogeneous, it is better to mix it not with a shovel, but with a mixer. The quality of the solution is important in any case, especially when pouring a warm floor and laying tiles. For 5 kg of cement-sand mixture, 1 liter of water is needed. It is necessary to add the mixture to the water, and not vice versa. After preparing the solution, it should stand for 1-2 minutes, and then it must be mixed again. Pouring cement mortar along beaconsis carried out by a rule. To simplify your work, you can buy a ready-made solution. If you want to get a perfectly flat surface, you can use a self-leveling screed, this option is chosen when it is necessary to lay tiles, linoleum or laminate. The composition of the self-leveling screed includes cement, gypsum and anhydrite. If you need a small thickness of the screed, up to 5 cm, then there are special solutions with microfibers that reinforce the screed and make it stronger. You can buy either a dry screed or a completely ready-to-use solution. Return to the table of contents</a>

Pouring cement mortar along beaconsis carried out by a rule. To simplify your work, you can buy a ready-made solution. If you want to get a perfectly flat surface, you can use a self-leveling screed, this option is chosen when it is necessary to lay tiles, linoleum or laminate. The composition of the self-leveling screed includes cement, gypsum and anhydrite. If you need a small thickness of the screed, up to 5 cm, then there are special solutions with microfibers that reinforce the screed and make it stronger. You can buy either a dry screed or a completely ready-to-use solution. Return to the table of contents</a>

Casting mortar

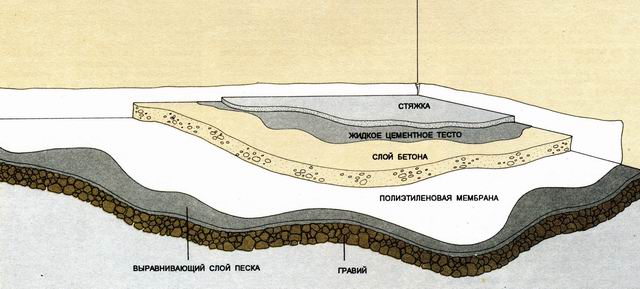

Three-stage cement floor diagram.This stage of work should be started from the corner that is furthest from the door. If you are working together, one person prepares the solution and the other pours it. The solution is poured onto the floor, then adjusted with a trowel and tightened with a rule, moving towards the exit of the room. The rule is moved along the beacons, making oval movements with it, such as when grouting walls. It is necessary to try to fill the room in one go, only in this case you will be able to get a monolithic and durable floor. After the solution hardens and retains its shape, the guides must be removed. When you can move around the floor, you need to seal the seams from the guides. If you use beacons, then you do not need to remove them from the screed, so the work is significantly accelerated and simplified. Although the screed will harden in a day, this does not mean that it is ready for use. In order for the floor to gain strength characteristics, it must remain without load for at least 7 days, but 21 days are better. To prevent concrete cracking, the screed should be moistened with water twice a day. To make the concrete stronger and to harden faster, a plasticizer can be used when preparing it. Return to contents</a>

Three-stage cement floor diagram.This stage of work should be started from the corner that is furthest from the door. If you are working together, one person prepares the solution and the other pours it. The solution is poured onto the floor, then adjusted with a trowel and tightened with a rule, moving towards the exit of the room. The rule is moved along the beacons, making oval movements with it, such as when grouting walls. It is necessary to try to fill the room in one go, only in this case you will be able to get a monolithic and durable floor. After the solution hardens and retains its shape, the guides must be removed. When you can move around the floor, you need to seal the seams from the guides. If you use beacons, then you do not need to remove them from the screed, so the work is significantly accelerated and simplified. Although the screed will harden in a day, this does not mean that it is ready for use. In order for the floor to gain strength characteristics, it must remain without load for at least 7 days, but 21 days are better. To prevent concrete cracking, the screed should be moistened with water twice a day. To make the concrete stronger and to harden faster, a plasticizer can be used when preparing it. Return to contents</a>

We estimate the quality of the work performed

Conduct an external inspection of the floor, it should beuniform in appearance and have a gray color. To determine how even the floor is, you need to take a rule, preferably 2 m long, and apply it to the floor surface. It is considered normal when the gaps between the rule and the floor do not exceed 4 mm. To determine the hardness of the coating, you need to hit it tangentially with a hammer, while the trace should be almost invisible. In order to cover 7-8 square meters of floor, you will need up to 10 bags of cement, it all depends on the thickness of the screed. To save money, you can first make a rough screed, using lower quality materials, and then make a finishing screed. The use of reinforcement, although it increases the cost of work, significantly increases the service life of the coating. Foam concrete screed is considered a more economical option, but it cannot be laid on the ground, first you need to make a rough screed with ordinary concrete.