Almost all floor coverings require thatunder them was an ideal horizontal base. Only in this case can you make a level floor in the room. Even a wooden floor, seemingly not touching the base, is easier to arrange on joists that rest on a plane without bumps. The main leveling element of the floor is still the screed. The recommendations that will be given below will help make the surface for finishing with any flooring material - from tiles to laminate. Only on a perfectly flat horizontal base can you make a level floor.

Only on a perfectly flat horizontal base can you make a level floor.

Preparatory stage

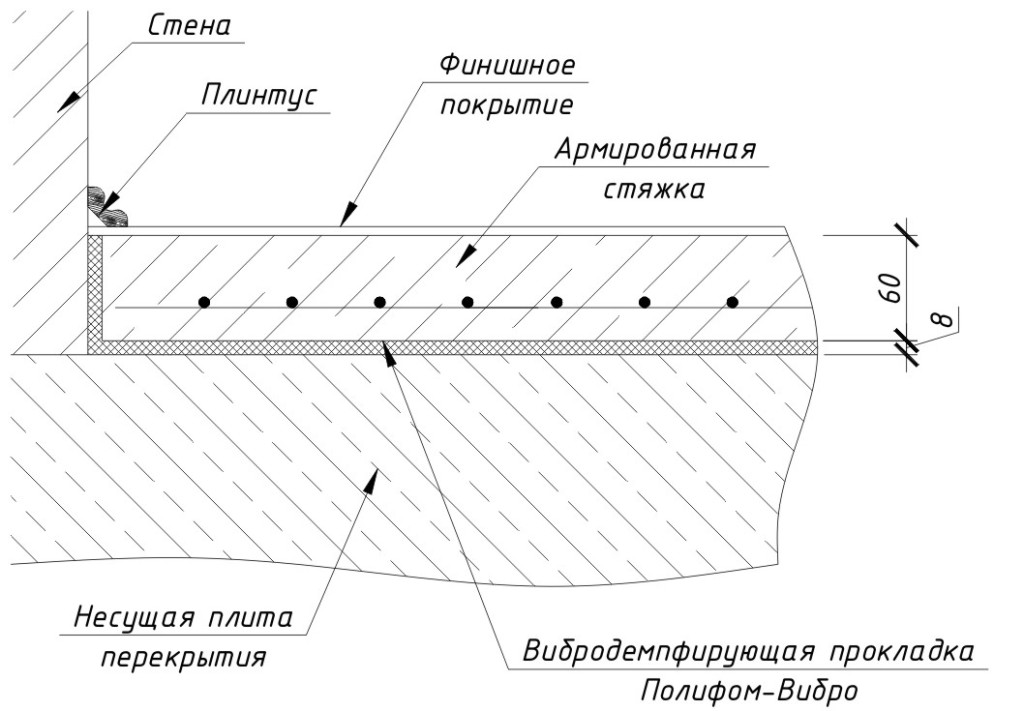

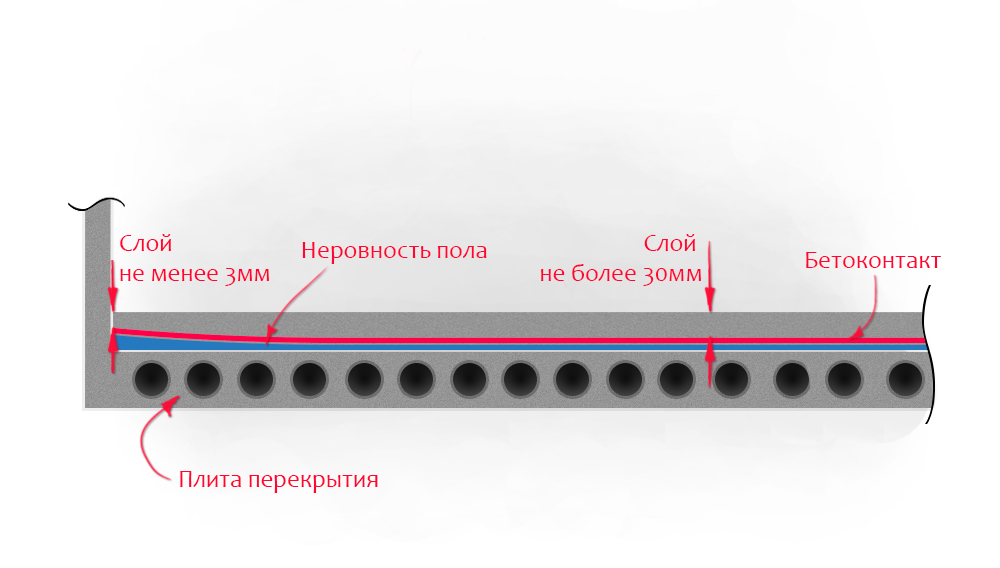

You will get a strong and durable floor screedonly if you properly prepare the surface for its installation. As much as you would like to skip this step and simply spread the mortar over the old coating, you will still have to remove it to the base. After this, all the remains of the screed, debris and dust are removed. Any cracks in the ceiling are sealed with mortar, and the surface itself is thoroughly dried. After this, waterproofing is laid on the slab. So, to remove the old coating and prepare the base for the new one, you will need: Scheme of floor leveling with concrete screed.

Scheme of floor leveling with concrete screed.

- perforator;

- shovel;

- trowel or spatula;

- broom;

- cement-sand mortar.

Before laying the waterproofing material, the surface mustbe treated with antifungal compounds. They are applied to the floor with a brush or roller. After the impregnation has dried, the floor is primed. The floor screed is installed after its waterproofing. A thick polyethylene film and roll materials based on bitumen can be used as a moisture-repellent membrane. Today, there are also liquid mastics that can be applied to the floor in one or more layers. Polyethylene is laid on the base with an overlap on the walls. The height of the overlaps should slightly exceed the thickness of the future coating. Roofing felt is laid in the same way. The edges of adjacent sheets of both film and bitumen material should overlap each other. The joints of the polyethylene are pasted over with tape, and the joints of the roofing felt are poured with bitumen. The waterproofing agent is fixed to the wall so as not to interfere with further work. Now the floor screed will be protected from moisture, which without the membrane could destroy it from below. Return to the table of contents</a>

Plotting a plane

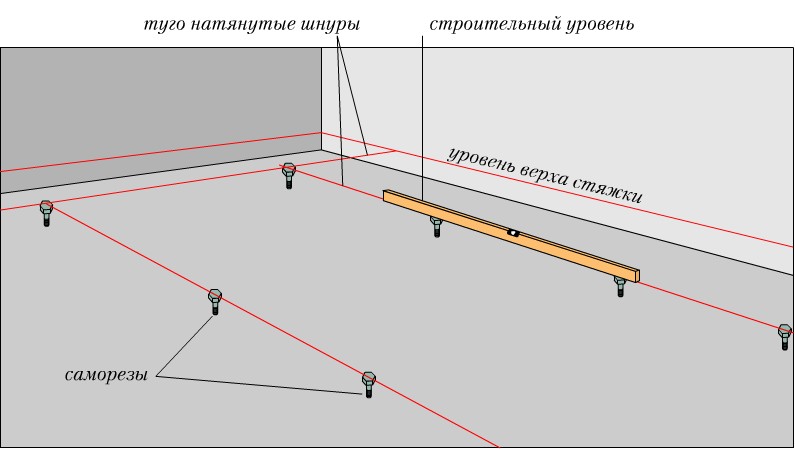

Before making a floor screed, you need to create a horizon that will make it easier to pour. For this stage of surface leveling, the following will be useful: Guideline for floor leveling.

Guideline for floor leveling.

- hydro level;

- long ruler with a level;

- a piece of chalk;

- a painting line;

- dowel-nails;

- alabaster or gypsum;

- hammer drill;

- Screwdriver;

- trowel;

- metal beacons;

- synthetic yarn.

Now take chalk and hydraulic in your handlevel. Make a mark on the wall of the room near some corner. The point can be located at any height from the floor, as long as it is convenient for you to make the markings, but it is best to do it at a height of 1.5 m. Using the level, make another mark on the other side of the wall. Make markings on the other surfaces of the room in the same way. On walls longer than 3 m, it is better to make more than 2 points. Adjacent marks on the walls are connected by lines beaten off with a chalk-rubbed painter's cord. You have the so-called zero horizontal, starting from which you will create the floor plane. Scheme of a self-leveling floor.To do this, you need to measure the distance from the line to the floor at equal intervals. In most cases, the height of the overlap in different areas will differ. Take the smallest gap between the horizontal and the floor as a basis and subtract the screed thickness from it. At this distance from the horizontal, make marks on the walls and draw lines with a cord. Drill holes along them, drive dowel nails into the walls and stretch threads between the opposite surfaces. The result is the plane of the future floor. Beacons are installed under the threads. The first and last profiles are placed 10-15 cm from the walls. The distance between the beacons should be 15-20 cm less than the length of the rule. The beacons are directed from the far wall to the door to the room. The profile is laid on slides made of gypsum or alabaster diluted with water. The distance between the gypsum supports is 25-30 cm. If the beacon protrudes from the plane, then it is pressed into the slide with a construction ruler and level. Additional portions of mortar are applied to supports of insufficient height. The horizontal is checked again using a ruler with a level, applied along and between the beacons. Return to contents</a>

Scheme of a self-leveling floor.To do this, you need to measure the distance from the line to the floor at equal intervals. In most cases, the height of the overlap in different areas will differ. Take the smallest gap between the horizontal and the floor as a basis and subtract the screed thickness from it. At this distance from the horizontal, make marks on the walls and draw lines with a cord. Drill holes along them, drive dowel nails into the walls and stretch threads between the opposite surfaces. The result is the plane of the future floor. Beacons are installed under the threads. The first and last profiles are placed 10-15 cm from the walls. The distance between the beacons should be 15-20 cm less than the length of the rule. The beacons are directed from the far wall to the door to the room. The profile is laid on slides made of gypsum or alabaster diluted with water. The distance between the gypsum supports is 25-30 cm. If the beacon protrudes from the plane, then it is pressed into the slide with a construction ruler and level. Additional portions of mortar are applied to supports of insufficient height. The horizontal is checked again using a ruler with a level, applied along and between the beacons. Return to contents</a>

Filling and leveling the screed

The work must be carried out at a temperature of 15 to25° C. It is advisable to complete the pouring of the floor in one go, otherwise cracks may appear in it later. In addition, the quality of the screed is affected by the homogeneity of the solution composition. It is necessary to ensure that each batch is carried out in exactly the same proportions as the first. The following tools are required for the work: Tools for floor leveling.

Tools for floor leveling.

- shovel;

- rule;

- Master OK;

- semifunctional;

- putty knife;

- pliers.

Pour the solution into the space between the wall andthe first 2 profiles. Run the rule along the beacons. Pull the device towards you. The rule removes excess mortar and forms a flat surface. After leveling (after 20-30 minutes), the area can be rubbed with a float. Fill the next square to the right or left of the first. Move towards the entrance, not forgetting to rub the leveled areas. The screed is not ready yet. After 2-3 days, the beacons should be removed from it, since there is a possibility of rust forming on them, which will come out over time. To make it easier to remove the profile, marks should be made on the walls when laying it. The beacons are pulled out with a scraper, which exposes the edge of the profile. Then pliers or pincers come into play. The remaining cracks are sealed with a primer, after which they are filled with mortar. The mixture is leveled with the rest of the surface with a spatula. Do not remove the profile immediately after pouring the screed, this will have a more detrimental effect on its integrity. In a month, the coating will be ready for laying tiles or a wooden floor. Within 3-5 days, the floor screed must be moistened with water. In the first ten days, the solution must harden under a polyethylene film. Return to the table of contents</a>

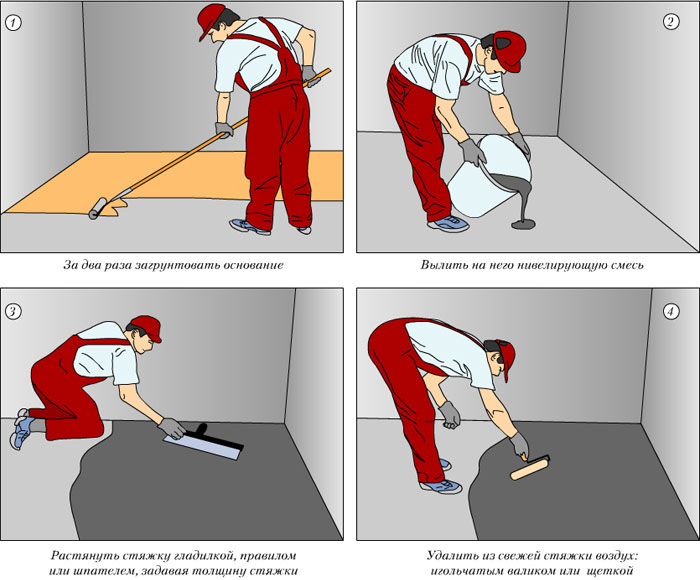

How to make leveling screeds in bulk materials

Scheme of using self-leveling mixture.The screed made of mortar has already created a smooth surface ready for finishing with many materials, but the ideal plane of the floor is achieved by laying a self-leveling floor. In addition, it will create a durable and strong waterproof film on the screed. In addition, it can serve both as a floor covering and as a base for further finishing. Still, the screed is subject to some shrinkage, so the self-leveling floor can correct this drawback. Before pouring it, the screed is primed to seal microcracks in the surface. An expansion compensator - a damper tape - must be laid along the walls (it is removed after the work is completed, and the remaining groove is sealed with a sealant). It is necessary to work with self-leveling floors in the absence of drafts. Each layer of the coating should not be thicker than 0.5 cm. Pouring a medium-thick mixture also begins from the area farthest from the door. The self-leveling floor is leveled with a squeegee. Air bubbles form in the solution during pouring. To get rid of them, before the mixture hardens, you should roll the surface with a needle roller. You can step on the self-leveling floor only in shoes specially designed for this work. A few hours after application, the self-leveling floor will harden. Complete hardening will be completed in 3-4 days.</ ul>

Scheme of using self-leveling mixture.The screed made of mortar has already created a smooth surface ready for finishing with many materials, but the ideal plane of the floor is achieved by laying a self-leveling floor. In addition, it will create a durable and strong waterproof film on the screed. In addition, it can serve both as a floor covering and as a base for further finishing. Still, the screed is subject to some shrinkage, so the self-leveling floor can correct this drawback. Before pouring it, the screed is primed to seal microcracks in the surface. An expansion compensator - a damper tape - must be laid along the walls (it is removed after the work is completed, and the remaining groove is sealed with a sealant). It is necessary to work with self-leveling floors in the absence of drafts. Each layer of the coating should not be thicker than 0.5 cm. Pouring a medium-thick mixture also begins from the area farthest from the door. The self-leveling floor is leveled with a squeegee. Air bubbles form in the solution during pouring. To get rid of them, before the mixture hardens, you should roll the surface with a needle roller. You can step on the self-leveling floor only in shoes specially designed for this work. A few hours after application, the self-leveling floor will harden. Complete hardening will be completed in 3-4 days.</ ul>