When furnishing a modern Russian apartmentIt often happens that you can't find a table in a store that would suit all parameters: cost, size, shape, color. In such a situation, all that remains is to decide: how to make a table with your own hands? The main advantage of this approach is the ability to get the piece of furniture you need and save up to 60-70% of your money. The simplest and most common option— a table with a rectangular tabletop and four straight legs. The table can be a classic dining table, extendable or collapsible, a coffee table, a serving table, a desk table, a computer table, or a summer house table. The only difference is in the size and shape of the tabletop, the length, shape and material of the legs. The tabletop can be round, oval, square, rectangular, made of laminated chipboard, solid wood or boards and equipped with one, two or four legs. If we are talking about legs, you can buy ready-made ones in a hardware store, or you can make them yourself. The easiest option is to make a table with a rectangular tabletop and four legs purchased in a store, which can be placed in the dining room or living room.

The simplest and most common option— a table with a rectangular tabletop and four straight legs. The table can be a classic dining table, extendable or collapsible, a coffee table, a serving table, a desk table, a computer table, or a summer house table. The only difference is in the size and shape of the tabletop, the length, shape and material of the legs. The tabletop can be round, oval, square, rectangular, made of laminated chipboard, solid wood or boards and equipped with one, two or four legs. If we are talking about legs, you can buy ready-made ones in a hardware store, or you can make them yourself. The easiest option is to make a table with a rectangular tabletop and four legs purchased in a store, which can be placed in the dining room or living room.

Materials and Tools

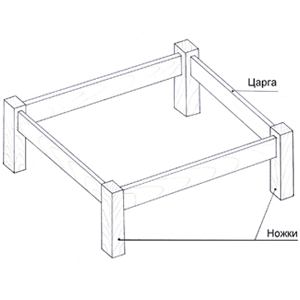

The set of materials depends on the type of countertop:Laminated chipboard, solid wood or wooden boards (oak, walnut, birch), 10x10 cm beams, ready-made legs, nails, screws, PVA glue, stain, varnish (paint). The tools you will need are a saw, jigsaw, drill (screwdriver), sander (sandpaper), tape measure, level, pencil, gloves and glasses. The height of the dining table is 75 cm. The finished legs look something like in image 1. Image 1.Scheme of table leg elements Chrome or gold-plated legs are not suitable for an apartment, so it is better to choose "matte metallic" or "bronze". The tabletop can be:

Image 1.Scheme of table leg elements Chrome or gold-plated legs are not suitable for an apartment, so it is better to choose "matte metallic" or "bronze". The tabletop can be:

- from the chipboard;

- from solid wood;

- or boards.

Return to Contents</a>

How to make a table with a table top made from chipboard?

Необходимо учесть, что толщина листа 16 или 18 mm, so you will have to join two layers and glue them with plastic edging. To do this, you will need an iron and a file. The edge must be applied to the end of the future tabletop and pressed with a heated iron, gradually moving it forward. The glue should change color and stand out a little beyond the edge. The plastic and glue are cooled with a rag soaked in cold water. Image 2.Scheme for making leg supports for a kitchen table. If you are making a table with your own hands with a solid wood tabletop, the best material is beech 45-50 mm thick. Solid wood is one board with a natural pattern, the edges of which need to be glued with a perforated strip (baguette) or an end strip. Experts advise sewing plywood to the bottom surface, which is 10 cm smaller in size than the tabletop. This will prevent deformation when the wood dries out during operation. Making a table with your own hands from several boards is a little more difficult. They need to be fastened together using bars and screws. The screws should be long enough not to damage the front surface. If you buy unsanded boards, you will have to sand them using a grinding machine (or sandpaper). After sanding, the material is impregnated with stain. Return to contents</a>

Image 2.Scheme for making leg supports for a kitchen table. If you are making a table with your own hands with a solid wood tabletop, the best material is beech 45-50 mm thick. Solid wood is one board with a natural pattern, the edges of which need to be glued with a perforated strip (baguette) or an end strip. Experts advise sewing plywood to the bottom surface, which is 10 cm smaller in size than the tabletop. This will prevent deformation when the wood dries out during operation. Making a table with your own hands from several boards is a little more difficult. They need to be fastened together using bars and screws. The screws should be long enough not to damage the front surface. If you buy unsanded boards, you will have to sand them using a grinding machine (or sandpaper). After sanding, the material is impregnated with stain. Return to contents</a>

Assembling the elements of the table

Assembling a table with your own hands - fasteningstandard legs for the table top (if it is made of laminated chipboard or solid wood). The advantage of "store" legs is that there is no need to install the frame. They are easy to attach (image 2). If the table top consists of several boards, then a box is mounted from the beams using self-tapping screws. The boards must be laid out on a flat surface with the front side down, the box is placed on them, and its inner contour is outlined. Beams are attached inside this contour, which should ensure the integrity of the table top. Then, using metal corners and self-tapping screws, the contour is attached and the legs are mounted. Such a table can be disassembled in a few minutes if necessary, and it costs several times less than a similar structure with wooden legs.