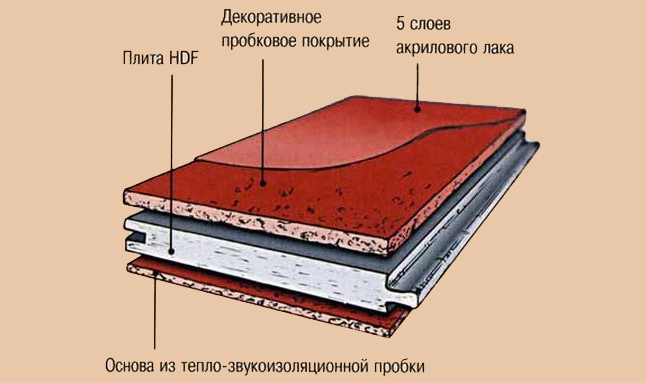

Among the modern materials thatare used when laying flooring, a special place is occupied by natural and environmentally friendly cork. Such a floor is quite durable and comfortable. It is pleasant to walk on cork even with bare feet, as it is elastic and quite warm. All the characteristics of the cork floor are achieved due to the porous structure of the material. It consists of solid cells that are filled with a mixture of nitrogen and oxygen. Cork flooring diagram.Cork flooring is not capable of causing allergies and does not electrify. It is quite fireproof, is not subject to the effects of rot and fungi. Do-it-yourself is quite an interesting and creative process. After all, each of its components has a unique pattern.

Cork flooring diagram.Cork flooring is not capable of causing allergies and does not electrify. It is quite fireproof, is not subject to the effects of rot and fungi. Do-it-yourself is quite an interesting and creative process. After all, each of its components has a unique pattern.

Select the cork floor

If you decide to install a floorcork flooring, then you will face a difficult task of choice. The modern construction market offers a wide variety of these panels. When buying material, you should pay attention to the interior design of the room in which the repair will be carried out. After all, cork is rich in various patterns. Not all of them will be appropriate. Your personal preferences are also important. The price range of flooring depends on the manufacturer, appearance and thickness of the panels. Of all the variety of cork, there is the following classification:

- cork plywood;

- laminate;

- MDF panels;

- pressed crumb of cork.

Cork floor coverings:agglomerate, cork veneer, a mixture of veneer and agglomerate. Cork board is considered the most expensive type of this material. It is a cut of cork tree, which is covered with durable varnish. Such coating is produced in large slabs or rolls. To facilitate installation, a protective vinyl film may be present on the reverse side. Cork laminate has standard dimensions. The installation instructions correspond to the installation of ordinary material. MDF panels are in the middle price range. Very often they are confused with cork board, although in terms of characteristics they are closest to laminate. The base of these panels consists of MDF, on which pressed cork chips are applied. Only on top they are covered with varnished veneer 2-3 mm thick. The most budget version of the boards is made of pressed cork chips. They have a characteristic structure with small grains, similar to a champagne cork. Natural veneer is characterized by complex patterns against a background of yellow and brown shades. In terms of quality, chip tiles are not much inferior to solid veneer and can be an excellent option for cork flooring for a family with an average income. Return to contents</a>

Cork floor coverings:agglomerate, cork veneer, a mixture of veneer and agglomerate. Cork board is considered the most expensive type of this material. It is a cut of cork tree, which is covered with durable varnish. Such coating is produced in large slabs or rolls. To facilitate installation, a protective vinyl film may be present on the reverse side. Cork laminate has standard dimensions. The installation instructions correspond to the installation of ordinary material. MDF panels are in the middle price range. Very often they are confused with cork board, although in terms of characteristics they are closest to laminate. The base of these panels consists of MDF, on which pressed cork chips are applied. Only on top they are covered with varnished veneer 2-3 mm thick. The most budget version of the boards is made of pressed cork chips. They have a characteristic structure with small grains, similar to a champagne cork. Natural veneer is characterized by complex patterns against a background of yellow and brown shades. In terms of quality, chip tiles are not much inferior to solid veneer and can be an excellent option for cork flooring for a family with an average income. Return to contents</a>

Preparing to install the cork cover

Laying cork flooring yourself can be done in three ways:

- installation of flooring is similar to that of laminate;

- floating floor;

- installation of cork on the glue.

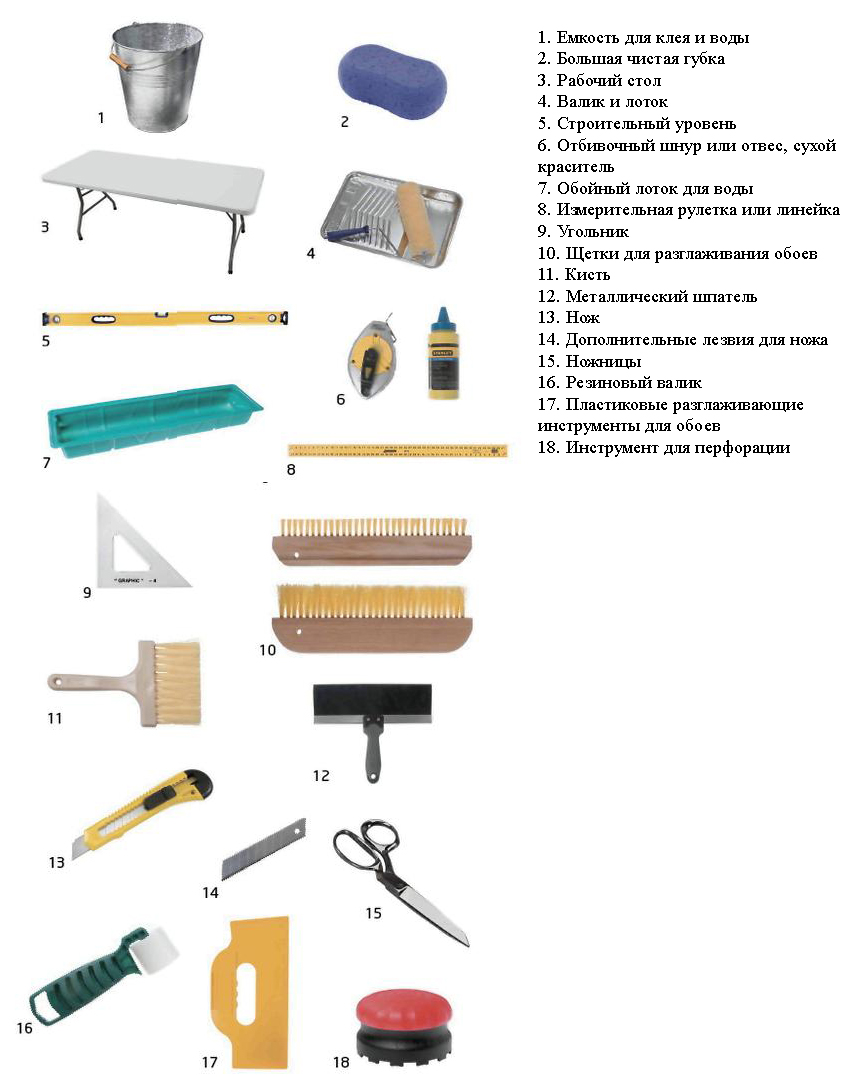

Tools for laying cork flooring.It is recommended to choose warm season for cork installation. Temperature difference during delivery should not exceed 7°C. After purchasing the material, it is advisable to leave it indoors to equalize the temperature. In addition, you should pay attention to the humidity level. When it reaches 70%, cork floor installation is not recommended. To install the flooring, you will need the following tools and materials:

Tools for laying cork flooring.It is recommended to choose warm season for cork installation. Temperature difference during delivery should not exceed 7°C. After purchasing the material, it is advisable to leave it indoors to equalize the temperature. In addition, you should pay attention to the humidity level. When it reaches 70%, cork floor installation is not recommended. To install the flooring, you will need the following tools and materials:

- electric jigsaw, which can be completely replaced by a Bulgarian;

- Rubber hammer;

- building level;

- plinth for cork floor;

- wedges for clearance around the perimeter of the masonry;

- roller and trowel when installing the cork on the glue;

- threshold for joints in the doorway;

- building corner.

The surface for laying the cork mustmeet some strict requirements. It is prohibited to install such a covering directly on the screed. This can lead to gradual crumbling of the cork slab. The floor surface must be perfectly dry, because the panels tend to instantly absorb moisture. For leveling, use a liquid agent to prevent damage to the fragile material. Return to contents</a>

"Floating" technology for laying cork floors

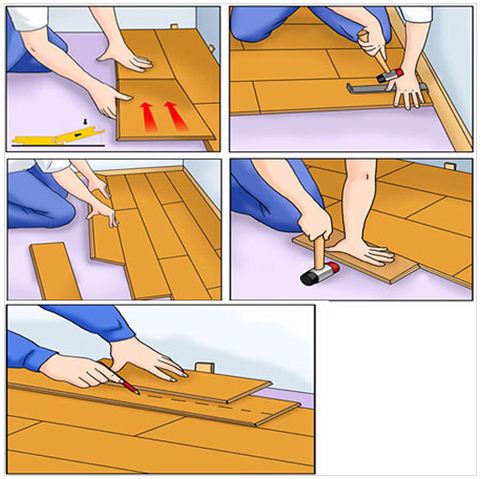

Photo 1.Cork flooring installation sequence. Installation of a "floating" floor is similar to installation of laminate. It is used for slabs with a locking connection. Installation of a cork floor begins with waterproofing works. You need to cover the entire room with polyethylene film. Leave a small reserve above the baseboards. The joints of the film must be carefully sealed with tape. A polypropylene base is laid on top of the film, the recommended thickness of which should be at least 0.2-0.3 cm. The sheets are installed end to end. Then we measure the length of the room across the direction of cork installation. This value should be divided by the width of the panel to calculate their required number. The extreme part should not exceed 0.5 cm. Cork flooring is installed from the right corner of the room. The ridge of the first row should be located towards the wall. After completing the installation of the cork along the starting line, wedges should be inserted to provide a gap around the perimeter. If the walls are crooked, the panel must be carefully trimmed. It is advisable to choose the direction of laying the cork floor from the window opening. The next row of the flooring starts from the end panel of the first row. If the previous line was laid without trimming, the initial component will have to be shortened to prevent the joints from coinciding (photo 1). The second row is connected to the first by installing the panel in the grooves at a right angle. After pressing it down a little, it can be lowered onto the base. We do the same with the next part of the flooring. For a stronger connection, it is advisable to tap the entire structure with a rubber hammer. When laying the cork, sometimes you have to bend around various pipes and other means of communication. In this case, it is recommended to leave a small gap of 0.1 cm. A special threshold is used to join the slabs in the doorway. It is attached to the floor itself with screws. After completing the work on laying the cork, you should immediately remove the wedges for the gaps. The baseboards are installed by attaching them to the wall, and not to the floor covering. Return to the table of contents</a>

Photo 1.Cork flooring installation sequence. Installation of a "floating" floor is similar to installation of laminate. It is used for slabs with a locking connection. Installation of a cork floor begins with waterproofing works. You need to cover the entire room with polyethylene film. Leave a small reserve above the baseboards. The joints of the film must be carefully sealed with tape. A polypropylene base is laid on top of the film, the recommended thickness of which should be at least 0.2-0.3 cm. The sheets are installed end to end. Then we measure the length of the room across the direction of cork installation. This value should be divided by the width of the panel to calculate their required number. The extreme part should not exceed 0.5 cm. Cork flooring is installed from the right corner of the room. The ridge of the first row should be located towards the wall. After completing the installation of the cork along the starting line, wedges should be inserted to provide a gap around the perimeter. If the walls are crooked, the panel must be carefully trimmed. It is advisable to choose the direction of laying the cork floor from the window opening. The next row of the flooring starts from the end panel of the first row. If the previous line was laid without trimming, the initial component will have to be shortened to prevent the joints from coinciding (photo 1). The second row is connected to the first by installing the panel in the grooves at a right angle. After pressing it down a little, it can be lowered onto the base. We do the same with the next part of the flooring. For a stronger connection, it is advisable to tap the entire structure with a rubber hammer. When laying the cork, sometimes you have to bend around various pipes and other means of communication. In this case, it is recommended to leave a small gap of 0.1 cm. A special threshold is used to join the slabs in the doorway. It is attached to the floor itself with screws. After completing the work on laying the cork, you should immediately remove the wedges for the gaps. The baseboards are installed by attaching them to the wall, and not to the floor covering. Return to the table of contents</a>

Laying the cork floor on the adhesive

Technology of laying the coating usinggluing starts from the center of the room. Then, clockwise, the cork is laid with a gradual increase in the working surface. It is recommended to lay out all the slabs on the floor before installation and determine the shift between them. It is allowed to lay the cork floor without shifting. There is no need to pre-cover the entire surface. To create the whole picture, you only need to lay out 2 m². It is not recommended to use PVA glue for laying cork on glue. It contains water, and cork panels tend to absorb moisture. There are special products for gluing cork slabs. When buying glue, pay attention to its drying time. Beginners are advised to use a product with a setting period of 10 minutes. Installation of cork covering on glue allows it to be spread on the floor or directly on the panel (video 1). After laying the cork, it should be pressed with a roller, carefully adjusted with a rubber hammer and be sure to check the evenness with a building level. A small gap should be left around the perimeter of the room. This coating will dry within a day or two.</ ul>