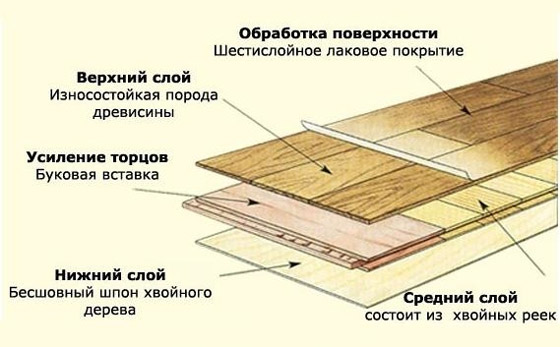

Parquet flooring has served faithfully for many centuriespalaces and rich houses. It was considered a symbol of wealth, creating a unique design. And even in our time, such a floor is quite expensive. Laying parquet with your own hands will significantly reduce its cost. Parquet board diagram.In addition to beauty, parquet is comfortable and durable. Many different design options and materials will satisfy any taste. Do-it-yourself installation of the flooring will ensure that all the owner's wishes are met.

Parquet board diagram.In addition to beauty, parquet is comfortable and durable. Many different design options and materials will satisfy any taste. Do-it-yourself installation of the flooring will ensure that all the owner's wishes are met.

Features of parquet

Parquet flooring is a type of finishingfloor covering, when the outer covering is made in the form of tightly laid wooden planks (piece parquet). Piece parquet is a plank 15-22 mm thick, 40-75 mm wide, up to 500 mm long. Each plank has a groove on one side and a comb on the other. They allow the planks to be joined during installation. The most common piece parquet is made from oak, ash and maple. Depending on the direction of sawing the wood and its type, there are several main types of piece parquet: select (longitudinal and cross-cut without defects in the wood structure); radial (only cross-cut); natural (cut in both directions with an emphasis on the natural defects of the wood); rustic (variegated color). The main advantages of parquet: a variety of possible laying forms, absolute harmlessness, high thermal insulation properties, sound insulation, mechanical strength, non-slip. Return to contents</a>

Types of laying parquet board

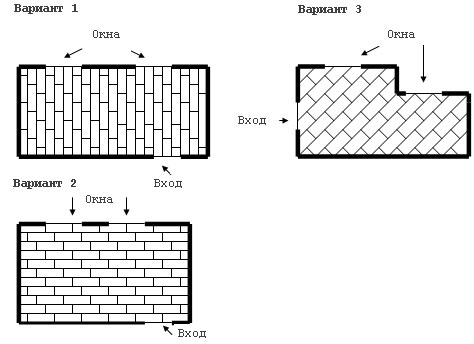

Technological table of parquet.The shape and properties of parquet flooring allow for various types of installation. The main types of parquet flooring arrangement that can be installed independently include deck installation, herringbone, square, diamond, and wicker. A more complex installation is the Sheremetyevo star. The simplest deck (regular) installation is characterized by a longitudinal arrangement of planks with each subsequent row offset relative to the previous one (usually by half a plank). A variation of deck installation is offset deck installation, when the planks are arranged in the same way, but with a general diagonal direction. Herringbone installation is performed using planks, each of which has a groove on two adjacent sides, and a ridge (tongue) on the other two adjacent sides. Planks can be installed at angles of 45 or 90 degrees to each other, but at an angle relative to the wall. Square installation means that the planks form a square of a given size. Then such squares are joined so that in adjacent squares the direction of the planks is opposite. It is possible to shift the squares relative to each other (chessboard effect). The braiding option is also based on the formation of squares, but in each square the planks are shifted relative to each other. The rhombic laying method differs from the square method in that the squares are located at an angle of 45 degrees to the wall. The Sheremetyevskaya star is a type of artistic laying and is made according to the specified installation parameters, using planks of different colors. Return to contents</a>

Technological table of parquet.The shape and properties of parquet flooring allow for various types of installation. The main types of parquet flooring arrangement that can be installed independently include deck installation, herringbone, square, diamond, and wicker. A more complex installation is the Sheremetyevo star. The simplest deck (regular) installation is characterized by a longitudinal arrangement of planks with each subsequent row offset relative to the previous one (usually by half a plank). A variation of deck installation is offset deck installation, when the planks are arranged in the same way, but with a general diagonal direction. Herringbone installation is performed using planks, each of which has a groove on two adjacent sides, and a ridge (tongue) on the other two adjacent sides. Planks can be installed at angles of 45 or 90 degrees to each other, but at an angle relative to the wall. Square installation means that the planks form a square of a given size. Then such squares are joined so that in adjacent squares the direction of the planks is opposite. It is possible to shift the squares relative to each other (chessboard effect). The braiding option is also based on the formation of squares, but in each square the planks are shifted relative to each other. The rhombic laying method differs from the square method in that the squares are located at an angle of 45 degrees to the wall. The Sheremetyevskaya star is a type of artistic laying and is made according to the specified installation parameters, using planks of different colors. Return to contents</a>

Methods of laying the coating

Options for laying parquet boards.There are two main ways to install parquet flooring: floating or using glue. The floating installation method involves only joining the planks using the tongue and groove system without additional adhesion to the floor base. This type of parquet is completely independent of humidity and temperature fluctuations, but requires careful adjustment of the joining elements. Parquet without adhesion to the base is easy to repair if necessary. The method of laying using parquet glue does not require special quality planks, but its production takes much more time. The floor base requires more careful preparation when laying parquet in this way. In principle, there is also a third method - mechanical fastening. It involves fastening the planks with nails or screws. This method of laying is rarely used nowadays. Return to contents</a>

Options for laying parquet boards.There are two main ways to install parquet flooring: floating or using glue. The floating installation method involves only joining the planks using the tongue and groove system without additional adhesion to the floor base. This type of parquet is completely independent of humidity and temperature fluctuations, but requires careful adjustment of the joining elements. Parquet without adhesion to the base is easy to repair if necessary. The method of laying using parquet glue does not require special quality planks, but its production takes much more time. The floor base requires more careful preparation when laying parquet in this way. In principle, there is also a third method - mechanical fastening. It involves fastening the planks with nails or screws. This method of laying is rarely used nowadays. Return to contents</a>

Floor preparation for laying parquet

Preparing the floor surface for layingpiece parquet largely determines the final quality of the work. The floor surface must be perfectly flat, horizontal and durable. The floor base must not oscillate under any vertical loads. In addition, the surface must ensure adhesion to the parquet glue. Parquet laying scheme.Before laying the parquet, it is necessary to check the humidity of the floor surface, which should not exceed 2%. If the humidity is higher, the floor should be dried. To strengthen the floor screed for laying the parquet, it is advisable to lay a plywood covering. First, the floor surface should be primed with a special adhesive composition. After the primer has dried, moisture-resistant plywood is fixed. Plywood sheets are laid with a gap of at least 5 mm. If you are going to lay piece parquet in the absence of a subfloor, you need to start with making a screed. The screed is made with a special cement mortar for the floor. After the solution dries, the screed is thoroughly cleaned. Then a layer of waterproofing is applied to it. For these purposes, it is better to use a special polymer film. The film is applied with an overlap of at least 20 cm. A layer of thermal insulation is applied on top of it. It is recommended to use rolled foamed polyethylene. Plywood sheets 10-18 mm thick are applied on top of the thermal protection. It is advisable to pre-cut the plywood into squares. The plywood squares are laid with a gap of about 40 mm. Start laying the plywood, stepping back from the wall by 1-1.5 cm. The plywood is fixed with glue. For reliable fastening, in addition to glue, it is better to use screws. After fixing the plywood, its surface must be sanded with a grinding machine. The horizontality of the floor must be checked with a level. Return to the table of contents</a>

Parquet laying scheme.Before laying the parquet, it is necessary to check the humidity of the floor surface, which should not exceed 2%. If the humidity is higher, the floor should be dried. To strengthen the floor screed for laying the parquet, it is advisable to lay a plywood covering. First, the floor surface should be primed with a special adhesive composition. After the primer has dried, moisture-resistant plywood is fixed. Plywood sheets are laid with a gap of at least 5 mm. If you are going to lay piece parquet in the absence of a subfloor, you need to start with making a screed. The screed is made with a special cement mortar for the floor. After the solution dries, the screed is thoroughly cleaned. Then a layer of waterproofing is applied to it. For these purposes, it is better to use a special polymer film. The film is applied with an overlap of at least 20 cm. A layer of thermal insulation is applied on top of it. It is recommended to use rolled foamed polyethylene. Plywood sheets 10-18 mm thick are applied on top of the thermal protection. It is advisable to pre-cut the plywood into squares. The plywood squares are laid with a gap of about 40 mm. Start laying the plywood, stepping back from the wall by 1-1.5 cm. The plywood is fixed with glue. For reliable fastening, in addition to glue, it is better to use screws. After fixing the plywood, its surface must be sanded with a grinding machine. The horizontality of the floor must be checked with a level. Return to the table of contents</a>

Stacking of parquet: instruction

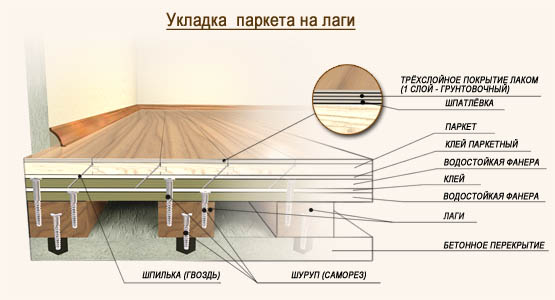

Scheme of laying parquet on joists.When laying parquet flooring in a deck (usual) manner, the installation of planks starts from the wall with a window, and you need to step back from it by 10-15 mm. The planks are laid parallel to each other, and the tongue of the plank should enter the groove of the adjacent one. The direction of laying is longitudinal to the direction of natural light. The first plank is laid in the corner of the floor along its full length. The next row is formed starting with a plank cut in half. This achieves a shift in the planks relative to each other in adjacent rows. The planks are cut with a jigsaw. Parquet glue is applied with a brush to the plywood surface and the lower surface of the parquet plank. You can connect the planks together by pushing the entire tongue into the groove of another plank or by inserting the tongue at a slight angle and gradually inserting the rest of the tongue into the groove. The planks must be connected tightly so that the planks are parallel to each other. In the process of forming rows, it is necessary to constantly check their parallelism to the wall. If the tenon is difficult to fit into the groove, you can lightly tap it with a rubber-coated mallet. On the planks that form the first row from the wall, it is necessary to saw off the tenon along the entire length. If you are laying piece parquet with your own hands diagonally, then the first row begins with laying a plank whose corners are sawn off at an angle. When laying in a herringbone pattern, the first row of planks along the side wall should form a straight line, for which pieces of planks are cut (beacon planks). It is better to form squares separately and fix them to the floor when assembled. They can be of different sizes: the side of the square is made of one plank or two planks. Return to contents</a>

Scheme of laying parquet on joists.When laying parquet flooring in a deck (usual) manner, the installation of planks starts from the wall with a window, and you need to step back from it by 10-15 mm. The planks are laid parallel to each other, and the tongue of the plank should enter the groove of the adjacent one. The direction of laying is longitudinal to the direction of natural light. The first plank is laid in the corner of the floor along its full length. The next row is formed starting with a plank cut in half. This achieves a shift in the planks relative to each other in adjacent rows. The planks are cut with a jigsaw. Parquet glue is applied with a brush to the plywood surface and the lower surface of the parquet plank. You can connect the planks together by pushing the entire tongue into the groove of another plank or by inserting the tongue at a slight angle and gradually inserting the rest of the tongue into the groove. The planks must be connected tightly so that the planks are parallel to each other. In the process of forming rows, it is necessary to constantly check their parallelism to the wall. If the tenon is difficult to fit into the groove, you can lightly tap it with a rubber-coated mallet. On the planks that form the first row from the wall, it is necessary to saw off the tenon along the entire length. If you are laying piece parquet with your own hands diagonally, then the first row begins with laying a plank whose corners are sawn off at an angle. When laying in a herringbone pattern, the first row of planks along the side wall should form a straight line, for which pieces of planks are cut (beacon planks). It is better to form squares separately and fix them to the floor when assembled. They can be of different sizes: the side of the square is made of one plank or two planks. Return to contents</a>

Grinding of parquet

Once the flooring is complete,it is sanded. A special parquet sanding machine is used for this. The task of sanding is to remove all the unevenness at the joints of the parquet planks and to create a single, even surface. The corners of the floor are sanded with another tool - an angle grinder with a special attachment. Sanding is done in two stages. First, a hard attachment is used to remove all the unevenness. Then a softer attachment is installed, polishing the surface. Return to contents</a>

Toning and varnishing of parquet

Tools for laying parquet boards.Before carrying out the final operations, the parquet surface is cleaned of dust using a vacuum cleaner. Parquet tinting is done with special mixtures intended for this purpose. The composition is applied evenly and rubbed onto the entire surface. The tinted parquet must dry completely. Varnishing is done after a new thorough cleaning of the surface. The varnish is applied with a brush in three layers. After applying each layer, it is necessary to allow time for drying. The drying time is about 24 hours. The installation of the coating is completed by mounting and fixing the baseboard, which will hide all the inaccuracies of the installation at the junction with the wall. The tool required for laying block parquet:

Tools for laying parquet boards.Before carrying out the final operations, the parquet surface is cleaned of dust using a vacuum cleaner. Parquet tinting is done with special mixtures intended for this purpose. The composition is applied evenly and rubbed onto the entire surface. The tinted parquet must dry completely. Varnishing is done after a new thorough cleaning of the surface. The varnish is applied with a brush in three layers. After applying each layer, it is necessary to allow time for drying. The drying time is about 24 hours. The installation of the coating is completed by mounting and fixing the baseboard, which will hide all the inaccuracies of the installation at the junction with the wall. The tool required for laying block parquet:

- Grinder;

- angle grinder;

- electric jig saw;

- Bulgarian;

- a hammer;

- mallet;

- grinding mesh;

- Screwdriver;

- hacksaw;

- level;

- roulette;

- the meter line;

- paint brush;

- platen roller, knife.

Parquet is a comfortable and beautiful flooringcovering. Its durability and aesthetics depend on the quality of laying the piece parquet with your own hands. If you follow the basic rules, laying the parquet yourself is quite accessible and feasible.