Today, self-leveling floorto do it yourself is more expensive than installing a regular cement-sand screed. However, it is also more effective. Self-leveling flooring allows you to create a high-quality rough base for decorative flooring. Such a base is characterized by reliability and durability. Self-leveling floor is necessary asrough base for the final decorative coating. In this way, the base can be prepared much faster: self-leveling coatings are fully ready for use in a week, while a regular cement screed dries for at least three weeks. Despite this, such a screed is not suitable for leveling surfaces with height differences greater than 3 cm. It can only be used to level out minor floor irregularities. The high cost is not an obstacle to using self-leveling mixtures. Especially if you know how to correctly calculate the necessary materials.

Self-leveling floor is necessary asrough base for the final decorative coating. In this way, the base can be prepared much faster: self-leveling coatings are fully ready for use in a week, while a regular cement screed dries for at least three weeks. Despite this, such a screed is not suitable for leveling surfaces with height differences greater than 3 cm. It can only be used to level out minor floor irregularities. The high cost is not an obstacle to using self-leveling mixtures. Especially if you know how to correctly calculate the necessary materials.

What is the consumption of self-leveling mixtures?

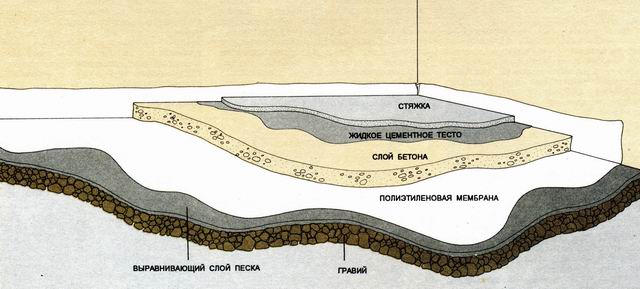

Floor area determination diagram.In order to pour the floor yourself without any problems (for example, not to finish the process ahead of schedule because the solution ran out at the wrong time), many components must be taken into account when calculating the amount of mixture. These include the size of the area to be poured, the planned thickness of the pouring layer, and the density of the working composition. To level the floor, the mixture consumption is compared with the quality of the base surface: its excellent condition implies a thin layer of the self-leveling mixture. To obtain a perfectly smooth rough screed, the layer thickness can be made about 1 mm, and its consumption will also be the smallest. The greater the number of distinguishable defects on the base, the thicker the pouring layer needs to be. It is for this reason that advance measures to prepare the base surface for pouring the self-leveling mixture make it possible to significantly reduce its consumption. The mass of the mixture is determined, among other things, by its purpose: much less mixture is consumed for a decorative finishing floor than for arranging leveling rough coatings. How to calculate the consumption of the composition? The following criteria are used in the calculations:

Floor area determination diagram.In order to pour the floor yourself without any problems (for example, not to finish the process ahead of schedule because the solution ran out at the wrong time), many components must be taken into account when calculating the amount of mixture. These include the size of the area to be poured, the planned thickness of the pouring layer, and the density of the working composition. To level the floor, the mixture consumption is compared with the quality of the base surface: its excellent condition implies a thin layer of the self-leveling mixture. To obtain a perfectly smooth rough screed, the layer thickness can be made about 1 mm, and its consumption will also be the smallest. The greater the number of distinguishable defects on the base, the thicker the pouring layer needs to be. It is for this reason that advance measures to prepare the base surface for pouring the self-leveling mixture make it possible to significantly reduce its consumption. The mass of the mixture is determined, among other things, by its purpose: much less mixture is consumed for a decorative finishing floor than for arranging leveling rough coatings. How to calculate the consumption of the composition? The following criteria are used in the calculations:

- thickness of the filler layer;

- structure density;

- additives in the form of special fillers to reduce the consumption of the mixture.

With the thickness of the fill layer taken equal to 1 mm,per square meter of area, you need to take 10 liters of self-leveling mixture. This volume is directly proportional to the density of the material used. In other words, for a density of one and a half kg per liter, the consumption of the mixture for a square meter will be 15 liters. Compositions from different manufacturers have different consumption. For example, Ceresit CN 69 - 1.8 kg per square meter, and our domestic Vetonit 3000 - 1.5 kilograms per 1 m². Return to contents</a>

Instructions for the development of self-leveling floors

To install a self-leveling floor, you will need a needle roller. To install a self-leveling floor, you need to prepare the following devices:

To install a self-leveling floor, you will need a needle roller. To install a self-leveling floor, you need to prepare the following devices:

- drill and nozzle for it;

- dishes for mixing;

- Needle roller.

Before starting the action, the floor surfaceclean from dust and seal the holes. The latter are often eliminated with the help of polyurethane foam. After the preparatory work, the base is covered with a primer and wait until it is completely dry. Pay enough attention to the primer. Insufficiently dense surfaces are treated several times. The effectiveness of all planned actions depends on the quality of the primer. The primer film will not allow the material that forms the base of the floor to swell and peel off. The next step is to apply the self-leveling mixture directly. For this purpose, dry powder is mixed in water in the ratio indicated on the packaging wrapper. First, fill the container with water, and then pour in the dry powder mixture. Mix the solution until it has a uniform consistency. Mixing is done with a drill attachment. Any improvised device is also allowed to mix the solution. However, a drill is more convenient and faster. Here you should take into account the nuance that the prepared solution will thicken right away. It must be used immediately. It is unacceptable to add liquid to the thickened solution. Pouring and leveling the mixture is the final procedure of the entire technology. The solution is poured onto the surface in small portions. It is poured in such a way that each subsequent portion is placed next to the previous one. The thickness of the self-leveling layer should be at least 5.0 cm. To give uniformity to the entire coating, a needle roller is rolled over the solution. Thanks to this, the solution is leveled, air bubbles are removed from it. Drying of the self-leveling screed lasts for 3 days to a couple of weeks (this is affected by the thickness and weather conditions). The final finishing of the floor is carried out only after the preliminary screed has completely dried. Return to the table of contents</a>

Some subtleties and rules of using technology

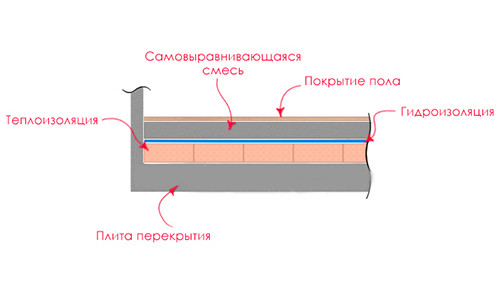

Scheme of the self-leveling floor device.At the stage of choosing a mixture, it is advisable to purchase all the necessary materials for arranging the screed from one manufacturer. Then there is a guarantee that all the ingredients of the solution will be best combined with each other. In particular, this is how you should approach the choice of the actual mixture and primer compositions. Considering the fact that the induced mixture has a short thickening period, the operations should be carried out at a fairly fast pace. Therefore, for work on arranging a self-leveling surface, it is best to use the services of a partner. Self-leveling screed is equally successfully used for the construction of industrial facilities and for residential ones. In housing, it finds its application as a coating on balconies, in bathrooms and kitchens. It is also used to make a rough base for flooring. Pouring a self-leveling mixture on a floor surface with your own hands is a procedure that any home craftsman will undertake to master with pleasure.

Scheme of the self-leveling floor device.At the stage of choosing a mixture, it is advisable to purchase all the necessary materials for arranging the screed from one manufacturer. Then there is a guarantee that all the ingredients of the solution will be best combined with each other. In particular, this is how you should approach the choice of the actual mixture and primer compositions. Considering the fact that the induced mixture has a short thickening period, the operations should be carried out at a fairly fast pace. Therefore, for work on arranging a self-leveling surface, it is best to use the services of a partner. Self-leveling screed is equally successfully used for the construction of industrial facilities and for residential ones. In housing, it finds its application as a coating on balconies, in bathrooms and kitchens. It is also used to make a rough base for flooring. Pouring a self-leveling mixture on a floor surface with your own hands is a procedure that any home craftsman will undertake to master with pleasure.